A LEADING

STEEL STRUCTURE CONTRACTOR

BMB Steel is a steel structure company specializing in designing and building pre-engineered steel buildings with the top outstanding quality in steel structural construction in Vietnam and Southeast Asia. BMB Steel proposes solutions and provides design, fabrication, and erection service packages for high-quality steel structures, optimal costs for projects and constructions such as shipyard building, international airport, exhibition center, hydroelectric plant, warehouse, factory, workshop, showroom, cold-storage, steel mill tower and a varietty kind of structural steel buildings.

Design

BMB Steel designs according to international

standards, gaining customer trust for many years by

providing quality and reasonable price solutions for structure

buildings.

More >

Fabrication

The high-quality engineers' crew proficiently

use calculation software and specialized design applications

to give clients quick feedback on the solution to the project,

and the overall estimates include proposal and approval

drawings.

More >

Installation

Providing complete construction solutions

for many types of projects: pre-engineered steel buildings,

steel structures, high-rise buildings, steel roof systems, and

many kinds of steel structure buildings. Fully customizable

buildings are built to your specifications, from warehouses/

factories to large-scale industrial projects for businesses

looking to develop production scale or expand business

models. We have the right solution for your vision.

More >

Safety

The construction practice goes through 4 steps to

ensure safety before putting into use: Project planning,

project implementation, project inspection, project

evaluation.

More >

Steel structure

+60,000

tons/year

Total of pre-engineered building areas

+2,000,000

sqm/year

Constructions

+3,000

projects

About Us

When constructing a factory, warehouse, or pre-engineered

steel building, you need specific and practical solutions to

optimize costs and meet your requirements for use and

aesthetic needs. With BMB Steel, we are one of the leading

pre-engineer steel buildings and steel structure contractors.

BMB Steel is proud of our staff, which has many years of

experience and is well-trained and specialized. Not only

that, but we have also received many large projects with the

trust of large, reputable partners. BMB Steel always brings

the best experiences to our customers with high-quality and

international-standard projects.

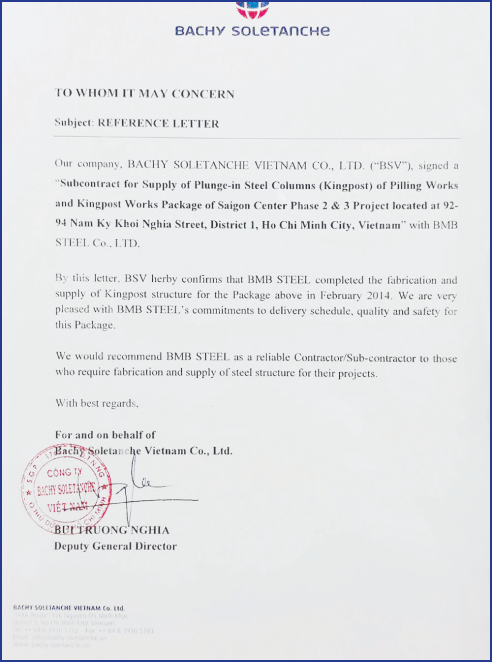

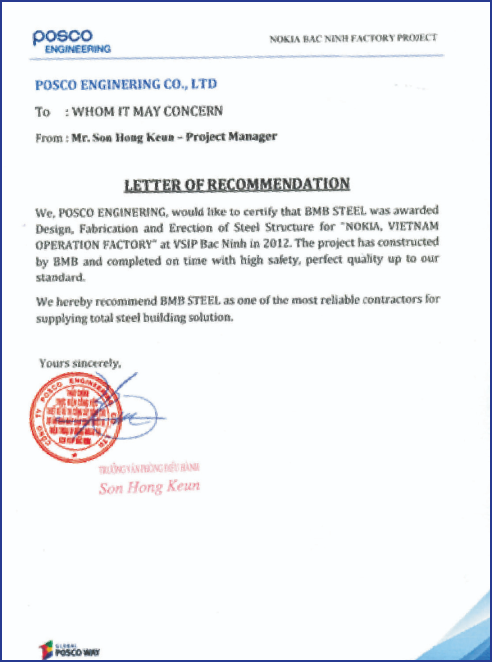

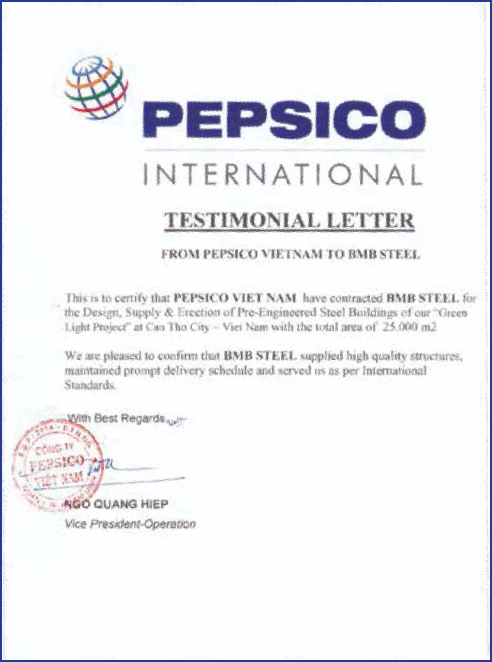

CLIENTs & PARTNERs

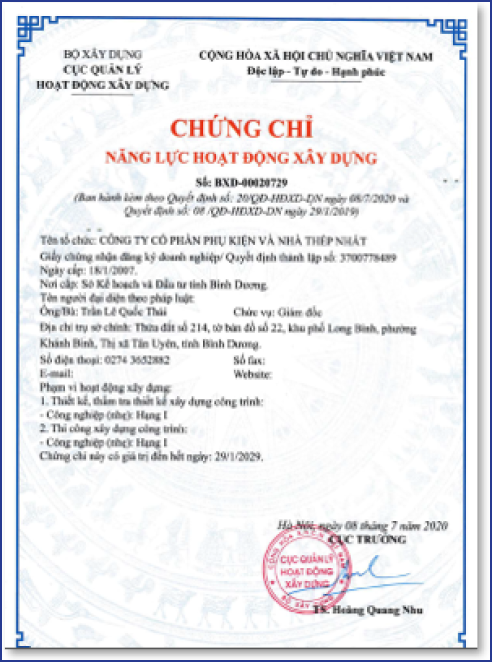

Awards and Certificates

News

On May 6, 2025, BMB Steel was honored to welcome over 30 final-year students from Ton Duc Thang University as part of the Factory Tour – Real-World Experience Program.

On April 25, 2025, the BMB Steel booth was set up at the University of Science and Technology to participate in the scho...

On April 21, 2025, BMB Steel officially celebrated 21 years of establishment and development.

On April 18, 2025, BMB Steel had the honor of being one of the businesses connected and accompanying all the students of...

On April 11, 2025, BMB's Myanmar branch was present in the Sagaing and Mandalay regions, which had just suffered a sever...

Sign up for a consultation

Click register we will call you for advice