Xuan Thanh Cement Project - Giant Dome

Each completed project marks an important milestone in BMB Steel's career. The project "Xuan Thanh Cement Factory" is also one of the typical projects that BMB Steel still remembers to this day because of the complexity of this work in the period of 2018–2020. A complex structural work must ensure the aesthetics as well as the quality of the work for the investor. Below is a detailed article about the project "Xuan Thanh Cement Factory", invite everyone to follow us to know more about this project!

1. Overall information about the project

Located at the southern gateway of Hanoi's capital, Ha Nam province has a diversified transportation system with roads (including National Highway 1A, Phap Van - Cau Gie expressway, the Cau Gie - Ninh Binh highway, and the system of national highways, provincial roads linking upland areas), North-South railway, and a river transport system. This is a favorable condition for the province to exchange economic, cultural, scientific, - technical information with other provinces and cities in the region and the whole country, especially the key economic region of the North; development of industrial-urban services. Here, the leadership of Xuan Thanh Cement Joint Stock Company decided to choose Thanh Nghi commune, Thanh Liem district, as the location for their cement plant.

Here is some preliminary information about the project:

|

Project Name |

Xuan Thanh Cement Factory |

|

Owner Name |

Xuan Thanh Cement Joint Stock Company |

|

Location |

Thanh Nghi commune, Thanh Liem district, Ha Nam province |

|

Construction contractor |

BMB Steel |

|

Total land square |

50,000 m2 |

|

Gross weight (tons) |

~2000 tons |

|

Time |

~210 days |

2. Xuan Thanh Cement Joint Stock Company

Xuan Thanh Cement Joint Stock Company, which belongs to the Xuan Thanh Group, is one of the leading cement manufacturers in Vietnam. With advanced technology, the most modern automation lines in the world of firms (LOSECHE GmbH, HAVER-BOECKER, FLSmidth, etc.) have confirmed their quality in domestic and foreign markets.

With abundant limestone raw materials, the best quality in Vietnam, right next to the factory, along with clay materials 5km from the factory, creating favorable conditions for production. The factory is only 1km from National Highway 1A and with the Day River system located along the length of the factory, it has created very favorable natural conditions for road and waterway traffic so that the factory's products can be supplied to customers. provinces in the country and exported to the international market with a total capacity of 5.5 million tons of cement/year/two lines.

The factory's second cement production line has equipment and technology designed and supplied by Flsmith Group - the Kingdom of Denmark, with more than 100 years of experience in the cement industry. The plant uses the world's most advanced dry rotary kiln system with a capacity of 12,500 tons of clinker/day, equivalent to 4.5 million tons of cement per year, making it the largest in the world. With the advanced drying technology of F.L. Smidth, Denmark. The whole factory is a closed, automatic production system. Equipment in the production line is designed and manufactured by famous firms in the European cement industry, such as Flsmith, Fls-Fuller, Siemens, etc. The factory's production process begins with receiving raw materials and fuels. Data for the production of products for customers is controlled completely automatically from the central control room (CCR)) through the computer system and PLC. At the factory, there is a PNGAA online rapid analysis system, a program to optimize ingredients, and an automatic control system with thousands of measuring points, ensuring continuous control and monitoring. ensure the best and most stable product quality.

The factory has a team of skilled personnel and technicians, well-trained in accordance with the process, along with the cooperation of German, Swiss, and Danish experts to help Xuan Thanh have strong human resources to meet future growth.

3. Project details

Upon receiving the winning bid from the investor, BMB engineers quickly proceeded to work and determined that this is a project of high complexity that needs to ensure aesthetics, accuracy, and quality at the same time, ensure the completion time of the project delivered to the customer. In this "Xuan Thanh Cement Plant" project, BMB decided to transport more than 2,000 tons of steel to serve the project built on 50,000 m2.

In more detail, for the roof and wall corrugated iron, we use 0.5 mm AZ150 thickness, color-coated aluminum zinc alloy corrugated iron in 9 waveforms, and opaque white corrugated iron with a thickness of 1.2 mm. This type of corrugated iron has the advantage that it is a zinc-aluminum alloy coating with an optimal composition ratio, high strength, and high resistance to corrosion and rust. Effective heat resistance, heat resistance, and a variety of colors and designs are suitable for many types of projects.

As for the paint, we chose Epoxy paint with a thickness of 120 microns, which is a paint widely used in the industry, especially floor paint for factory floors. Epoxy paint enjoys a lot of advantages from epoxy active ingredients and is widely applied in the construction of factory floor paint, basement paint, anti-static paint, antibacterial paint, etc. But in general, epoxy paint has advantages such as being Antibacterial, easy to clean, waterproof, anti-slip, wear-resistant, does not generate dust, has a good load capacity, etc.

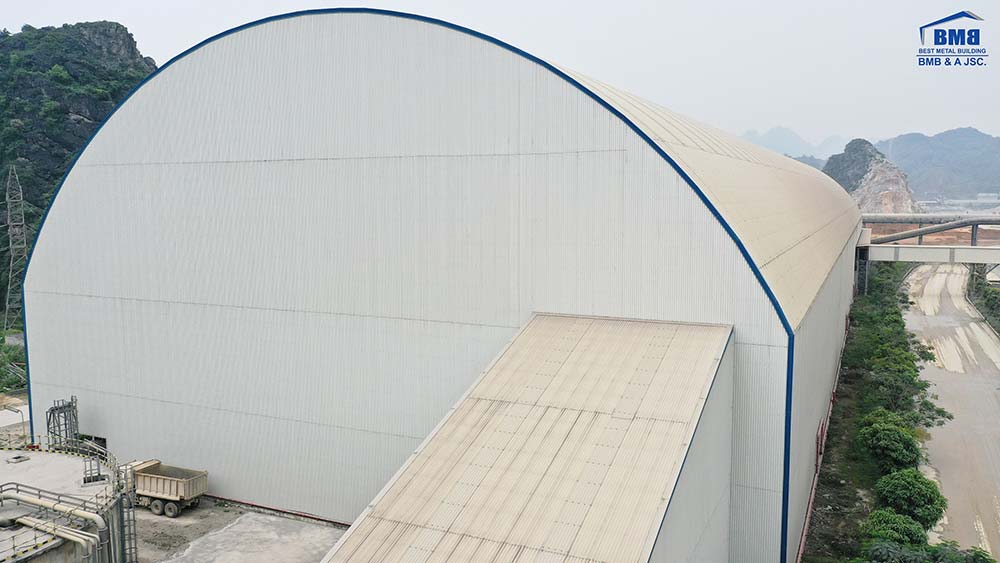

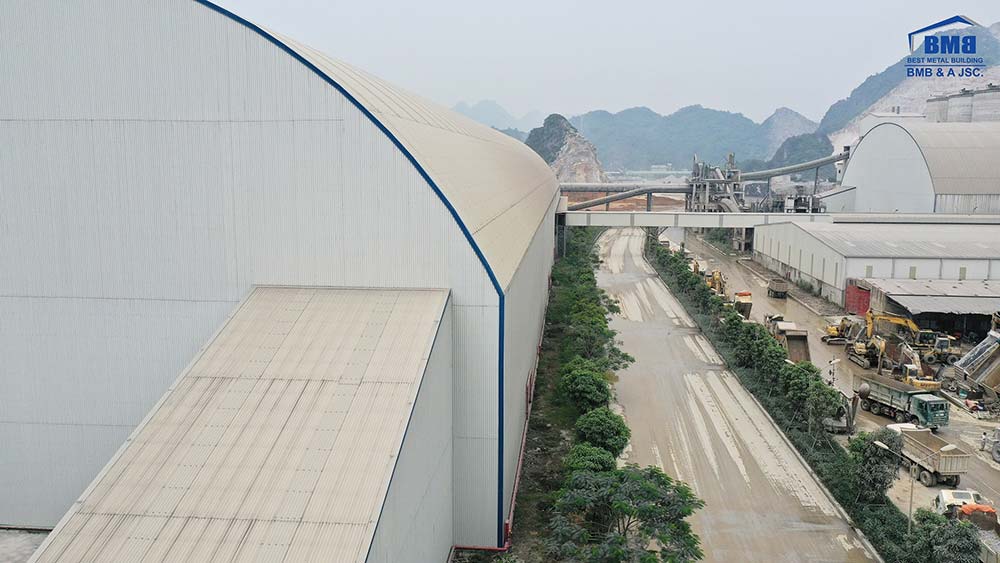

Solid dome structure, high aesthetic

The last step is the cleaning work to hand over to the customer. In the last days of staying with the project "Xuan Thanh cement factory", BMB Steel still works seriously with optimal productivity without delay neglecting work to improve the spirit of "work safety". This is also the criterion that BMB Steel has always adhered to since its establishment, assessing the success and reliability of investors when they come to BMB Steel.

4. Detailed pictures of project construction

Some typical images of the project

Looking back at the journey that BMB Steel went on with the project "Xuan Thanh Cement Factory", during that time, we and the investor always stuck together. BMB Steel understands the importance and expectations of investors when they choose us as the main contractor for their project this time. Although this project does not have a "superior" area like the others that BMB has built, it is a project that marks the outstanding maturity of BMB. We are always listening, sharing, and ready to serve our customers, from mid-range to high-level projects. Do not hesitate to contact BMB Steel if you are wondering how to choose the type of pre-engineered steel building for your project!