Why pre-engineered steel buildings considered a sustainable construction solution

- 1. The construction process of pre-engineered steel structures does not require much energy and material

- 2. The lifespan of pre-engineered steel structures is long

- 3. The change in design does not require lots of energy and materials

- 4. The material of pre-engineered steel structures can be recycled and reused for different purposes

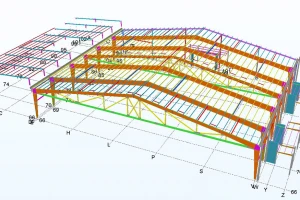

Sustainability has been a trend and priority in all industries worldwide. In the steel construction industry, construction enterprises are trying to investigate more thoroughly methods of sustainable construction. Compared to conventional steel building, pre-engineered steel building is considered to be a more sustainable construction method. This article shall discuss 4 main reasons why pre-engineered steel building is considered sustainable. In order to do that, we will focus on analyzing the life cycle of pre-engineered steel buildings.

1. The construction process of pre-engineered steel structures does not require much energy and material

Pre-engineered steel buildings usually save a lot of materials, energy, and space.

First of all, most details of a pre-engineered steel building are designed carefully and accurately fabricated in the factory. They are so exact that there is less chance of excess materials or errors during the construction process. What is more, nowadays, there are a variety of methods of design and fabrication that reduce an abundant amount of steel material. For example, to prevent wasting too much steel, engineers taper the sections based on the bending moment's shape. This design also helps enlarge space for other details of the building.

Another design method, section-moment simulation, involves creating lightweight structural parts, which makes the structure much lighter. This helps reduce a large amount of transportation costs and energy.

Besides, construction time, wastage, and energy of pre-engineered steel construction are much lower compared to conventional steel construction. This is because pre-engineered steel building details are designed and fabricated in the factory, then transported in a completely knocked-down condition to the construction site where they are erected with nut-bolts according to the construction plan. There is no time and energy wasted waiting for each step to be completed as in conventional steel construction. Assembling steel components with nut bolts leads to a decrease in the use of electricity and energy for the heating and cooling process, which cuts down on bills.

Not only does a reduction in the consumption of energy help customers save costs of building but it is also friendly to the environment.

2. The lifespan of pre-engineered steel structures is long

Another important factor that contributes to a sustainable structure is the long span, and it is proven that pre-engineered steel buildings are more durable over a high level of accuracy, so after the steel frames are built, they are unlikely to change shape or become loose over time. Accessories of the structures also remain close tightly, reducing the risks of air leaks.

Besides, most pre-engineered steel buildings are well-designed with a great ability of resistance to fire as well as other risks. They are also highly resistant to seismic force thanks to their flexible and light frames while the heavy structure of conventional steel buildings makes them less effective in seismic areas.

Thanks to their excellent structures, pre-engineered steel constructions can remain for decades without rotting and deteriorating under the harshest weather and roughest terrain.

3. The change in design does not require lots of energy and materials

Not only do pre-engineered steel buildings provide a large spacing for the owners to locate their racking system, equipment, and machinery, but they can easily be expanded or narrowed down.

Basically, pre-engineered steel structures are designed in a way in which they can be erected easily at construction sites. The structure is very flexible. For example, an expansion of the building can be made by removing the end of the building, erecting a new framework, and adding matching roofs and wall panels.

Compared to other types of construction, expanding a pre-engineered steel building does not require too much energy and time, which is profitable and sustainable in many ways.

4. The material of pre-engineered steel structures can be recycled and reused for different purposes

Another important factor of sustainable construction is the ability of the material to be reused afterward.

Since the building is made out of steel, once the life cycle is completed, pre-engineered steel buildings end up at a recycling center where they are melted and used for other purposes rather than being dumped at the local landfills.

This helps reduce a significant amount of construction and demolition waste, which helps save a lot of landfill space and protect the environment better.

The process of construction and maintenance of buildings consumes a significant amount of energy, which poses a huge negative impact on the environment. Therefore, choosing a suitable method for construction projects is the responsibility of every company and individual.

As per the above analysis, a pre-engineered steel building can be considered a sustainable method of construction because it is not expensive to maintain and improve, it is environmentally friendly and it helps reduce time, costs, and energy spent on the building process. Selecting pre-engineered steel buildings can be a good choice for your enterprise. Consider it and you will not regret it.

Above are some reasons why pre-engineered steel structures are considered sustainable. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.