Top 10 affordable mezzanine prefabricated house designs

- 1. What is a mezzanine prefabricated steel house?

- 2. Pros and cons of choosing a mezzanine prefabricated house

- 3. 10 latest mezzanine prefabricated house designs in 2025

- 3.1. Minimalist modern mezzanine prefabricated house

- 3.2. Stylish slanted roof mezzanine prefabricated house

- 3.3. Japanese-inspired mezzanine prefabricated house

- 3.4. Mezzanine prefabricated house with a small workshop

- 3.5. Mezzanine prefabricated house for mini apartments, homestays

- 3.6. Compact 3x12m mezzanine prefabricated house

- 3.7. Thai-style roof mezzanine prefabricated house

- 3.8. Green space mezzanine prefabricated house

- 3.9. Mezzanine prefabricated house for businesses

- 3.10. Industrial mezzanine prefabricated house

- 4. Important structural considerations when building a mezzanine prefabricated house

- 5. Construction process of a mezzanine prefabricated house

- 6. Comprehensive construction cost for mezzanine prefabricated houses

Mezzanine prefabricated houses are becoming a modern construction trend thanks to their affordable costs, quick construction time, flexible design. This type of house is especially suitable for small or narrow plots of land, offering a comfortable, aesthetically pleasing living space. In this article, BMB Steel presents 10 of the most notable affordable, modern mezzanine prefabricated house designs today, along with essential notes on structural systems and construction costs to help you easily choose the right design.

1. What is a mezzanine prefabricated steel house?

A mezzanine prefabricated house consists of one main completed floor with an additional small mezzanine level above. This mezzanine is not considered a full second floor as it occupies less than 80% of the main floor area.

Instead of reinforced concrete like in traditional construction, this house type relies on steel structures. Components such as columns, beams, purlins, etc. are pre-manufactured in factories according to technical drawings and design specifications provided by architects, then transported to the site for rapid assembly, significantly shortening construction time.

The mezzanine level is usually supported by sturdy horizontal beams and secondary columns, made from steel or engineered wood, ensuring strong load-bearing capacity. With its flexible design, the mezzanine prefab house is suitable for various purposes, including residential homes, rental rooms, storage spaces, small-scale workshops.

Read more: 13+ Modern popular industrial building drawings

2. Pros and cons of choosing a mezzanine prefabricated house

2.1. Pros of mezzanine prefabricated houses

Maximizes land usage

With its smart design, a prefabricated house with a mezzanine optimizes usable space. The mezzanine extends the living area without expanding the building’s footprint. This is especially beneficial for narrow or irregularly shaped plots where traditional construction methods are less feasible. The mezzanine can be used as a bedroom, workspace, living area, storage space.

Fast construction time

Thanks to prefabricated steel components manufactured in factories based on technical drawings, construction becomes quick and efficient. Installation is simple and a mezzanine prefab house can typically be completed within 1-2 months, significantly faster than conventional reinforced concrete buildings.

Cost-effective construction, increase benefit

Prefab materials and components are reasonably priced, which helps lower overall construction costs. Additionally, the shorter construction time means reduced labor and operational expenses. Used soon is also helping owner benefit. These houses also require less maintenance and are less prone to major damage, resulting in long-term savings for the owner.

Durable and safe

Steel frames are resilient against harsh weather conditions such as storms, floods, earthquakes. Unlike wood, steel is resistant to termites and warping, and unlike concrete, it doesn’t crack easily, ensuring long-lasting durability. Some structural systems are even fire-resistant, enhancing overall safety. Especially, steel structure can against earthquake very well.

Aesthetic and flexible

Mezzanine prefabricated houses not only meet functional needs but also offer strong aesthetic appeal, easily customizable to suit modern, minimalist, industrial styles. Their modular nature allows for easy assembly, expansion, relocation, or upgrading, providing great flexibility for future changes.

Read more: Collection of 15+ Modern Pre-Engineered Steel Structure Factory Design Drawings

2.2. Cons of mezzanine prefabricated houses

Prone to corrosion over time

Steel structures can be vulnerable in humid, rainy, coastal environments. Without proper treatment and maintenance, the steel frame may corrode.

Poor sound and thermal insulation

Due to the use of lightweight materials like steel, panel boards, prefabricated mezzanine houses typically have inferior soundproofing and thermal insulation compared to brick or concrete structures. Sound can easily echo and travel through partitions, affecting privacy. In hot seasons, indoor temperatures may rise quickly, while in winter, it can get quite cold. Therefore, additional air conditioning or specialized insulation systems are often necessary to ensure comfort.

3. 10 latest mezzanine prefabricated house designs in 2025

3.1. Minimalist modern mezzanine prefabricated house

This design features clean lines and neutral tones, ideal for homeowners who value simplicity and neatness in their living space.

Read more: Standard industrial factory construction process

3.2. Stylish slanted roof mezzanine prefabricated house

With its eye-catching slanted roof, this design not only adds a unique visual touch but also increases the ceiling height and airflow for the mezzanine area.

3.3. Japanese-inspired mezzanine prefabricated house

Using lightweight wooden furniture, sliding doors and a minimalist layout, this design creates a peaceful, warm, and elegant atmosphere inspired by traditional Japanese aesthetics.

3.4. Mezzanine prefabricated house with a small workshop

Perfect for home-based businesses, this model combines living space on the ground floor and mezzanine with a compact workshop or storage area in the back.

Read more: Top 7 reputable pre-engineered steel building construction companies in Ho Chi Minh City

3.5. Mezzanine prefabricated house for mini apartments, homestays

Compact yet fully functional, this design is optimized for short-term rentals. It offers a cozy, unique, and budget-friendly option for small homestays or rental units.

3.6. Compact 3x12m mezzanine prefabricated house

Designed to maximize use of narrow plots, this house stretches lengthwise with the mezzanine placed flexibly at the front or middle, perfect for small and tight land spaces.

3.7. Thai-style roof mezzanine prefabricated house

Blending a modern steel frame with a traditional Thai-style roof, this design creates an elegant, familiar aesthetic ideal for rural or suburban areas.

3.8. Green space mezzanine prefabricated house

This eco-friendly design incorporates natural light, green plants and skylights to create a refreshing, nature-connected living environment. The mezzanine is positioned to provide a view of the lush garden below.

3.9. Mezzanine prefabricated house for businesses

Ideal for small businesses, this design is suitable for use as a café, shop, small office. The mezzanine level extends usable space and can be utilized for seating, resting, or storage.

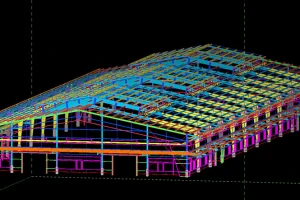

3.10. Industrial mezzanine prefabricated house

Designed for factories, warehouses, small-scale production facilities, etc., this model uses the mezzanine for offices, monitoring stations, storage.

4. Important structural considerations when building a mezzanine prefabricated house

When constructing a prefabricated house with a mezzanine, ensuring a solid and well-designed structural system is key to achieving a safe and long-lasting building. Below are three critical structural components you should pay attention to:

4.1. Main structure

This is the "backbone" of the entire house, including the foundation, primary steel frame, columns, beams, roofing system. All of these components must be carefully calculated to support the load of both the main floor and the mezzanine above.

4.2. Secondary structure

This includes elements such as exterior walls, partitions, staircases, roof purlins. While these parts do not bear the main structural load, they are essential for the house’s comfort and aesthetic appeal.

4.3. Shaping and enclosure structure

This is the finishing part, consisting of the main door system, windows, wall panels, etc. To create a visually appealing and harmonious design, architects often focus on the proportional balance of structural volumes, door placement, ceiling height. A few specific notes:

- Doors should be positioned in places that allow easy opening/closing and do not obstruct movement or interior layout.

- Common door dimensions: height from 1.8-2.1m, single-leaf door width around 650-800mm; double-leaf doors range from 1200-1400mm.

- Door materials should be durable, easy to install and low-maintenance in the long term.

5. Construction process of a mezzanine prefabricated house

To ensure a high-quality prefabricated mezzanine house, the construction process must follow a systematic and standardized procedure.

Step 1: Consultation and information gathering

The process begins when the client contacts a reputable construction companies. At this stage, you will receive detailed consultation on design options, dimensions, suitable materials, cost estimates tailored to your usage needs and budget.

Step 2: Site survey and project assessment

The construction team will survey the condition of the land, assess the geology, building location, other factors that impact the project’s durability, safety, load-bearing capacity, corrosion resistance, waterproofing.

Step 3: Technical drawing design

Based on the survey results and customer preferences, the companies will develop detailed technical drawings. These include the structural frame, electrical and plumbing systems, etc. Once completed, the drawings are submitted to the client for approval before moving to the construction phase.

Step 4: Preparation of construction permit documents

After the drawings are approved, the construction companies will assist the client in preparing the necessary legal documents to apply for a construction permit. This includes land ownership documents, technical drawings, safety reports and implementation methods in compliance with local regulations.

Step 5: Construction and installation

Once the permit is granted, steel frame components are fabricated in the factory and transported to the site for assembly.

Step 6: Finishing and handover

After the structural work is complete, the interior will be finished, systems checked, and the site cleaned. Finally, both parties will conduct an inspection and handover. If any part of the project does not meet the agreed standards, the client may request adjustments or corrections based on the contract.

6. Comprehensive construction cost for mezzanine prefabricated houses

The cost of building a prefabricated house with a mezzanine depends on various factors such as total construction area, types of materials used, design style and the desired level of finish.

To give you an overview, below is a reference price list for each category when constructing a mezzanine prefabricated house:

|

Category |

Unit price (VND/m²) |

|

Prefabricated steel frame |

1.200.000 – 1.600.000 |

|

Corrugated iron roof + purlins |

350.000 – 500.000 |

|

Mezzanine floor (panel or deck) |

700.000 – 1.200.000 |

|

Cladding walls (iron sheet, panel,etc.) |

450.000 – 650.000 |

|

Basic interior finishing |

1.000.000 – 1.500.000 |

|

Average total construction cost |

3.700.000 – 5.500.000 |

Below is a reference table of turnkey construction costs for mezzanine prefabricated houses:

|

Category |

Unit price (VNĐ/m2) |

|

30m² prefabricated steel house |

30.000.000 – 50.000.000 |

|

50m² prefabricated steel house |

125.000.000 – 150.000.000 |

|

100m² prefabricated steel house |

200.000.000 – 300.000.000 |

Note: The prices above include all stages from structural construction to basic finishing. Actual costs may vary depending on site conditions and specific project requirements.

A mezzanine prefabricated house is an ideal choice for those seeking a cost-effective, fast-construction and flexible housing solution. Whether used for residential, commercial or industrial purposes, these house models can be easily customized to meet practical needs. However, to ensure durability and safety, special attention must be given to the structural system and selecting a reputable construction companies. With the design ideas, pricing details, and construction process shared in this article, BMB Steel hopes to help you find the optimal solution for your future project.