Collection of 15+ Modern Pre-Engineered Steel Structure Factory Design Drawings.

- 1. Design drawings of pre-engineered steel factories and industrial buildings

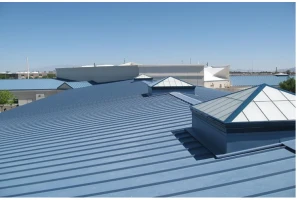

- 2. Factory and Industrial Building Design Drawing Samples

- 2.1 Level 4 Pre-Engineered Warehouse Drawing Sample

- 2.2 12m Pre-Engineered Steel Frame Factory Drawing Sample

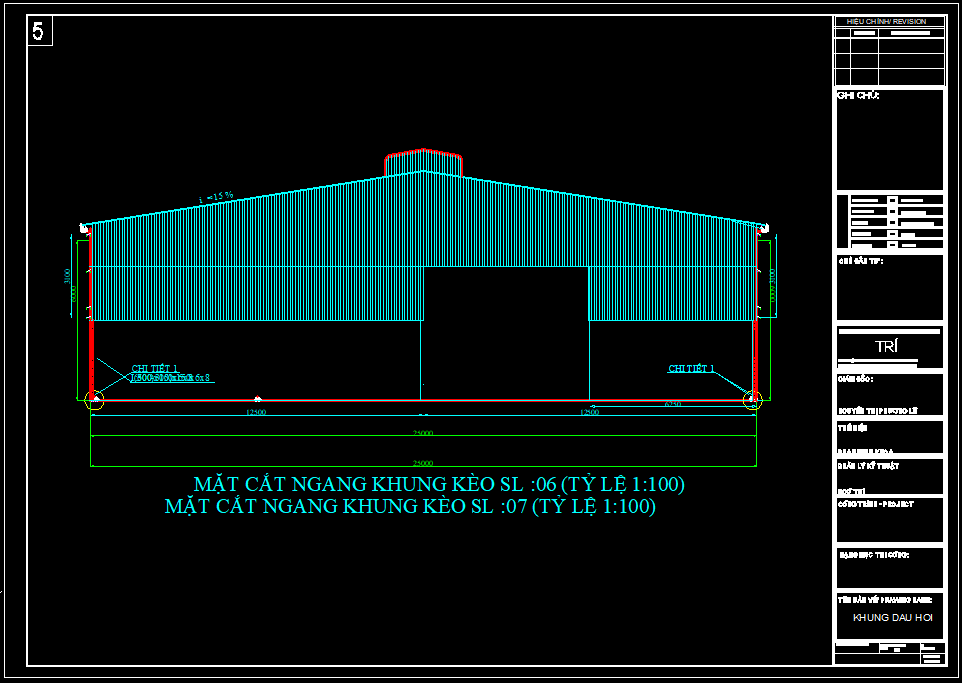

- 2.3 25m Pre-Engineered Steel Frame Factory Drawing Sample

- 2.4 300m2 Pre-Engineered Steel Frame Factory Drawing Sample

- 2.5 2000m2 Pre-Engineered Steel Frame Factory Drawing Sample

- 2.6 Pre-Engineered Agricultural Storage Warehouse Drawing Sample

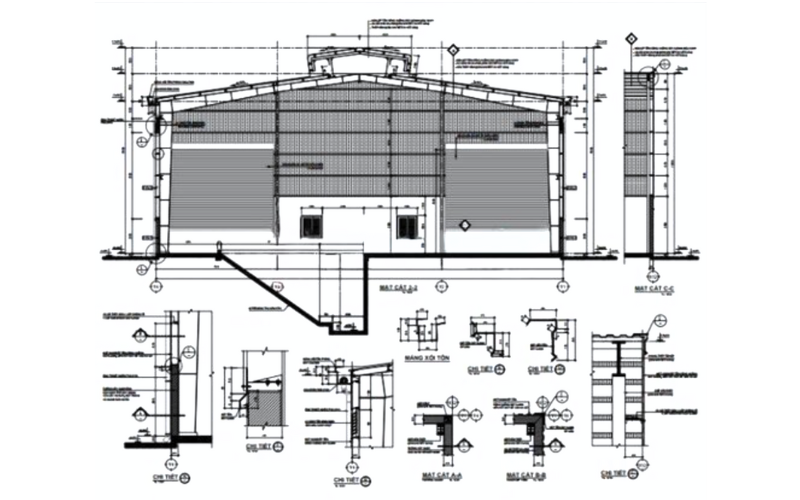

- 2.7 Single-Story Pre-Engineered Steel Frame Factory Drawing Sample

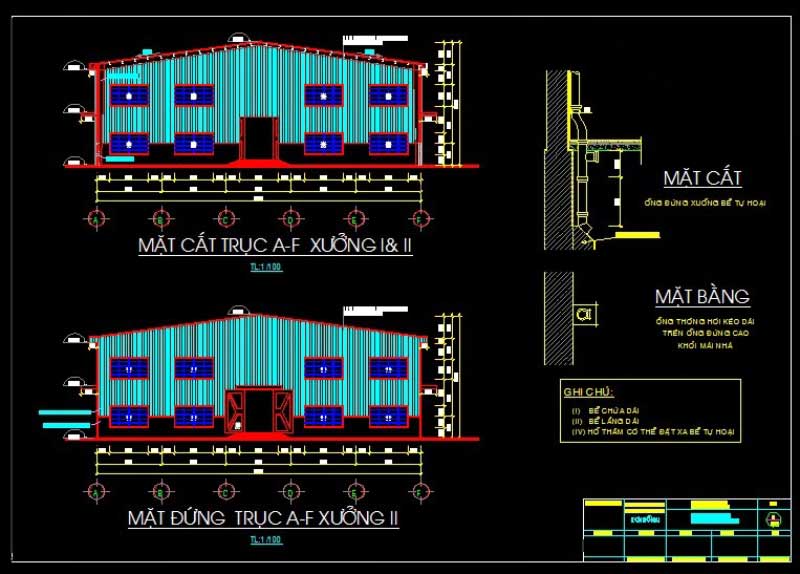

- 2.8 Garment Factory Drawing Sample

- 2.9 Mechanical Workshop Drawing Sample

- 2.10 Two-Story Pre-Engineered Steel Building Drawing Sample

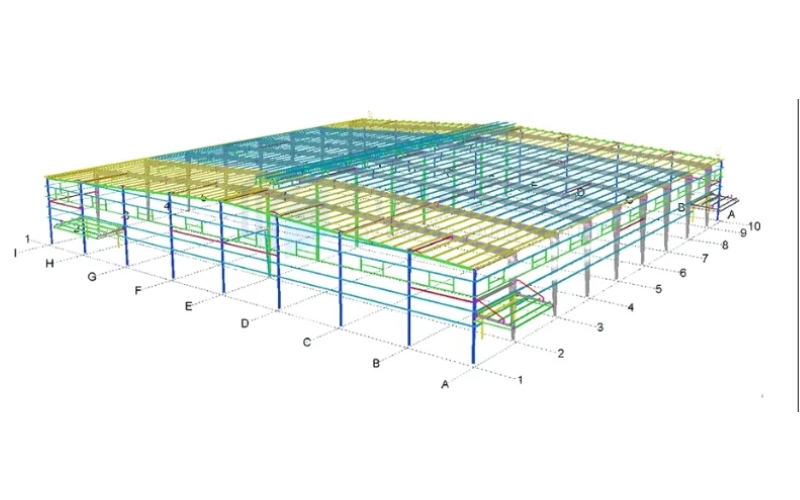

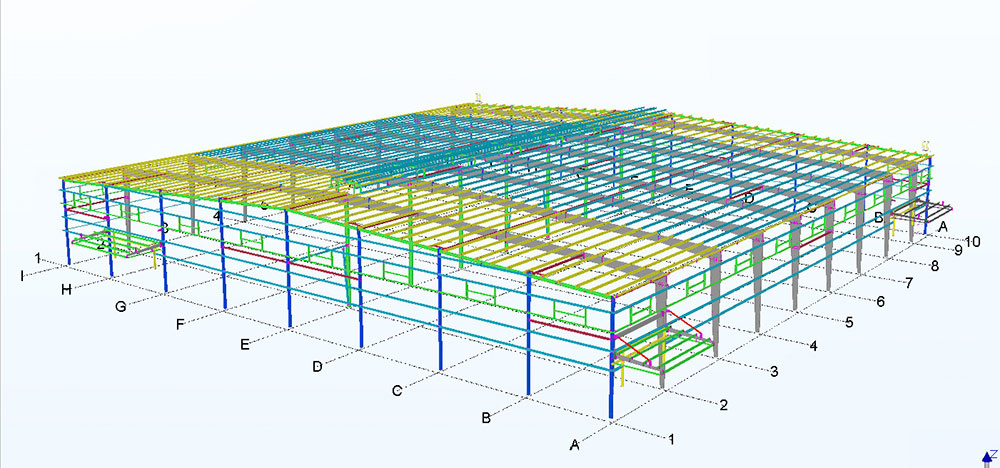

- 2.11 10,000m2 Industrial Factory Drawing Sample

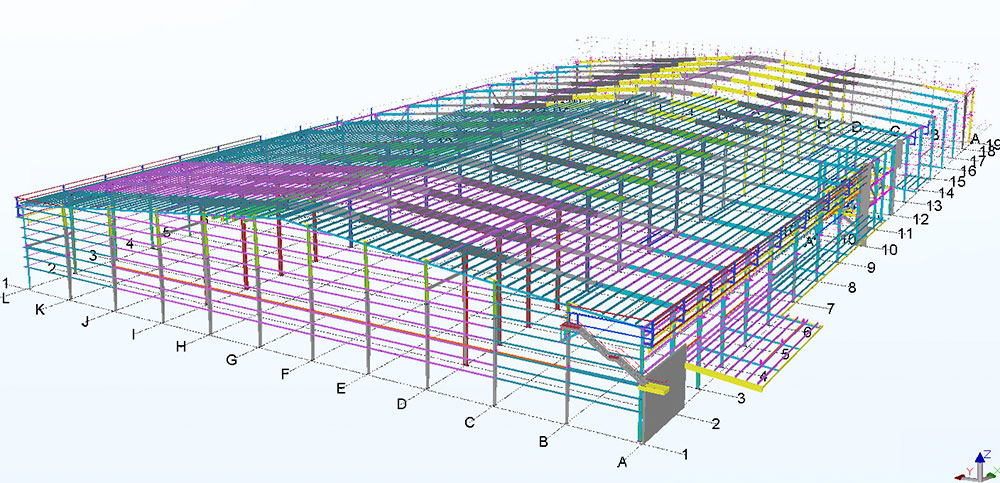

- 2.12 20,000m2 Industrial Factory Drawing Sample

- 2.13 30,000m2 Industrial Factory Drawing Sample

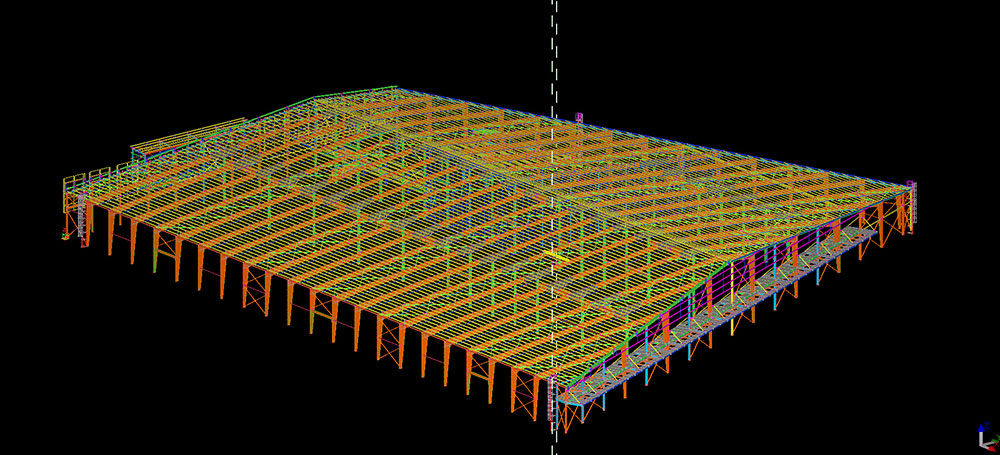

- 2.14 60,000m2 Industrial Factory Drawing Sample

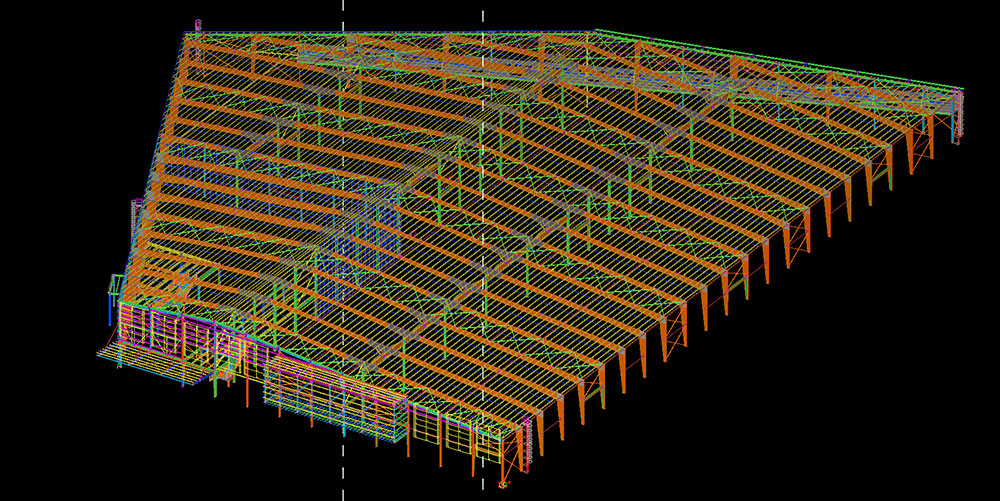

- 2.15 100,000m2 Industrial Factory Drawing Sample

- 3. Why are factory design drawings needed before construction?

- 4. Requirements of a factory construction design drawing

- 5. Steps to design industrial factory drawings

- 6. Important Considerations When Designing Industrial Factory Drawings

When constructing a project, the design drawing is indispensable and has to be entirely and meticulously prepared. A factory design drawing will describe all the required data to build a perfect building. How to make a professional design drawing? What are the requirements of factory construction design drawings? To learn more, let's figure out with BMB Steel in the article below.

1. Design drawings of pre-engineered steel factories and industrial buildings

Steel factory and industrial building drawings are descriptions that are illustrated by images and data parameters. It altogether provides readers with detail, structure, and what constitutes a building. In terms of purpose and designing plan, the more meticulous and legible the drawing is, the more standard the new construction will be. Moreover, only when these conditions are met can the cost of investment be determined.

It is compulsory to design the drawings of pre-engineered factories and industrial buildings from the first stages. Apart from using specialized technical support software, this step must be conducted by a highly qualified construction engineer. Thus, the drawing will achieve high accuracy, and the pre-engineered factory will be of the best quality.

2. Factory and Industrial Building Design Drawing Samples

BMB Steel has compiled beautiful and popular factory design and industrial building drawing samples currently in use. Let's explore:

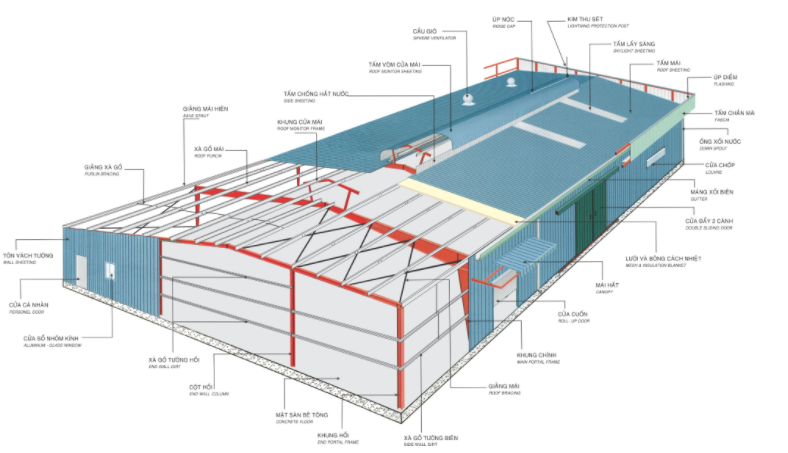

2.1 Level 4 Pre-Engineered Warehouse Drawing Sample

- Designed with compact scale, suitable for small and medium enterprises

- Drawings show simple structure, easy to construct

- Average height of 4-5m

- Allows flexible expansion according to needs

2.2 12m Pre-Engineered Steel Frame Factory Drawing Sample

- Large 12m span suitable for medium-scale warehouses or production facilities

- Design prioritizes flexibility with sloped or dome roofs for effective drainage

Important elements required in factory drawings:

- Overall floor plan and detailed area drawings

- Foundation and steel frame structure drawings

- Electrical, water, and fire protection system drawings

- Joint and connection details

- Materials and equipment statistics

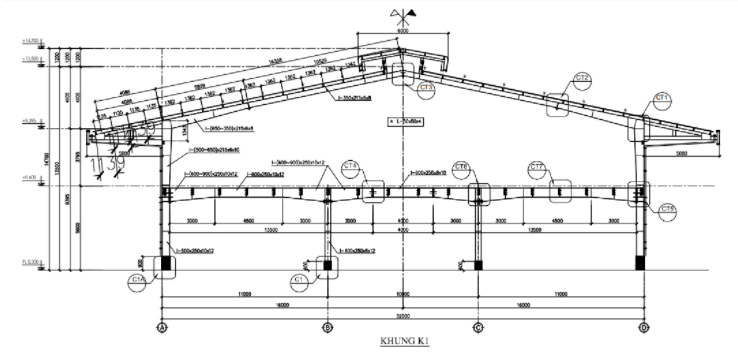

2.3 25m Pre-Engineered Steel Frame Factory Drawing Sample

- 25m design suitable for businesses needing large spaces

- Drawings clearly show column-truss system, connection system and foundation details for durability

2.4 300m2 Pre-Engineered Steel Frame Factory Drawing Sample

- Popular choice for medium enterprises

- Drawings show complete primary and secondary structural systems

- Investment cost ranges from 500-750 million VND depending on specific requirements

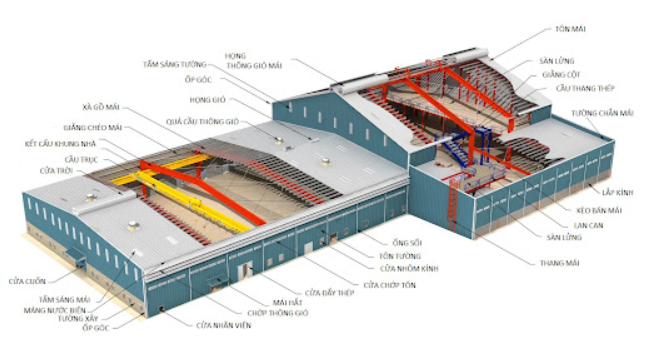

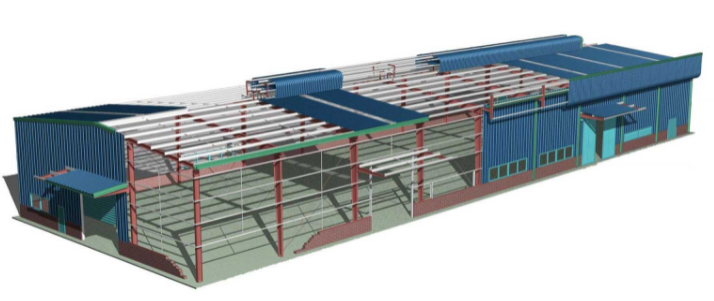

2.5 2000m2 Pre-Engineered Steel Frame Factory Drawing Sample

- Large-scale design suitable for industrial manufacturing plants

- Drawings include multiple functional zones like main production area, storage, management office with complex structural systems

2.6 Pre-Engineered Agricultural Storage Warehouse Drawing Sample

- Design specially focuses on insulation and preservation

- Drawings clearly show use of insulation materials like panels, ventilation systems and humidity control

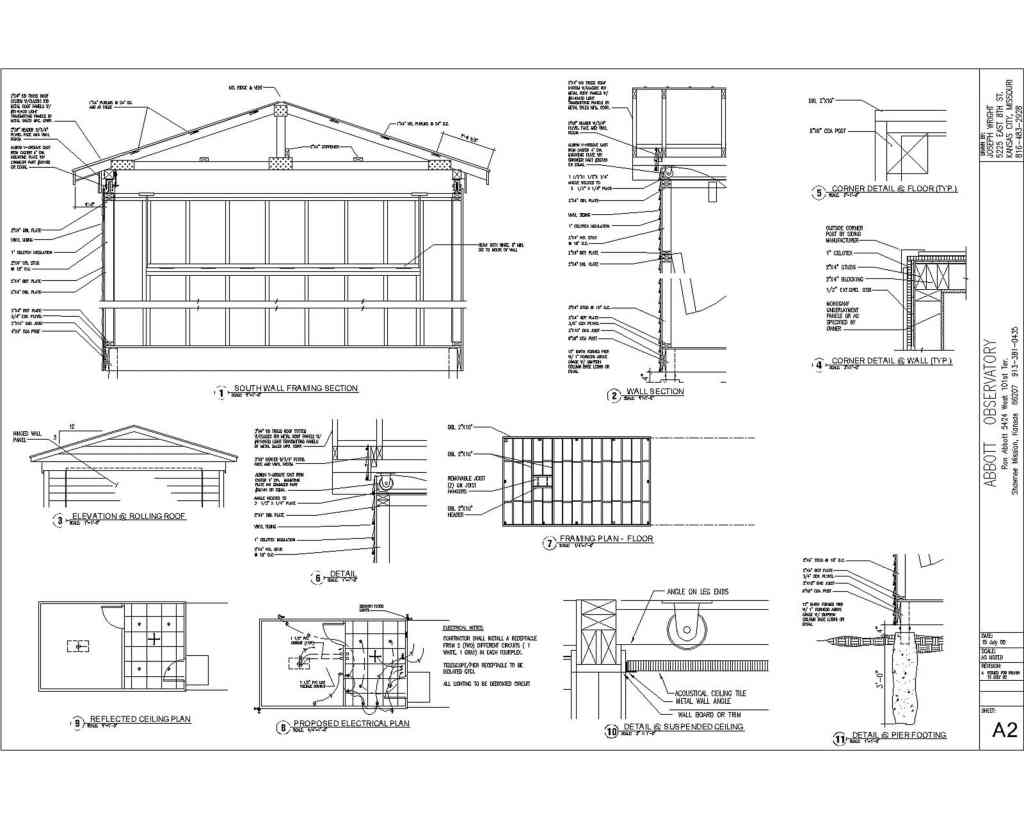

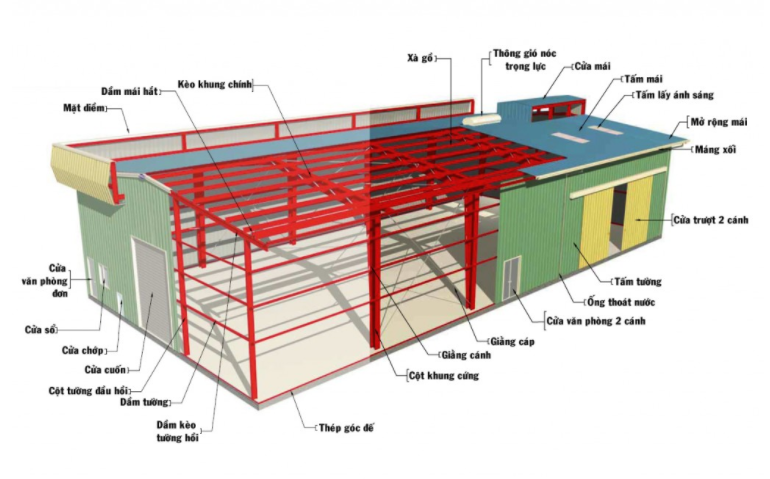

2.7 Single-Story Pre-Engineered Steel Frame Factory Drawing Sample

- Detailed technical document describing entire structure and components

- Important foundation for design, production and construction processes

- Ensures construction meets standards for safety and efficiency

2.8 Garment Factory Drawing Sample

- Optimized production line layout

- Detailed areas for cutting room, sewing area, raw materials storage and finished products

- Ensures smooth production flow

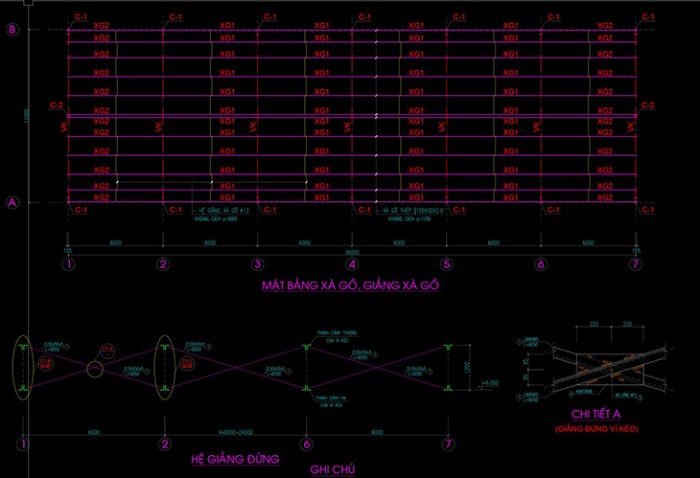

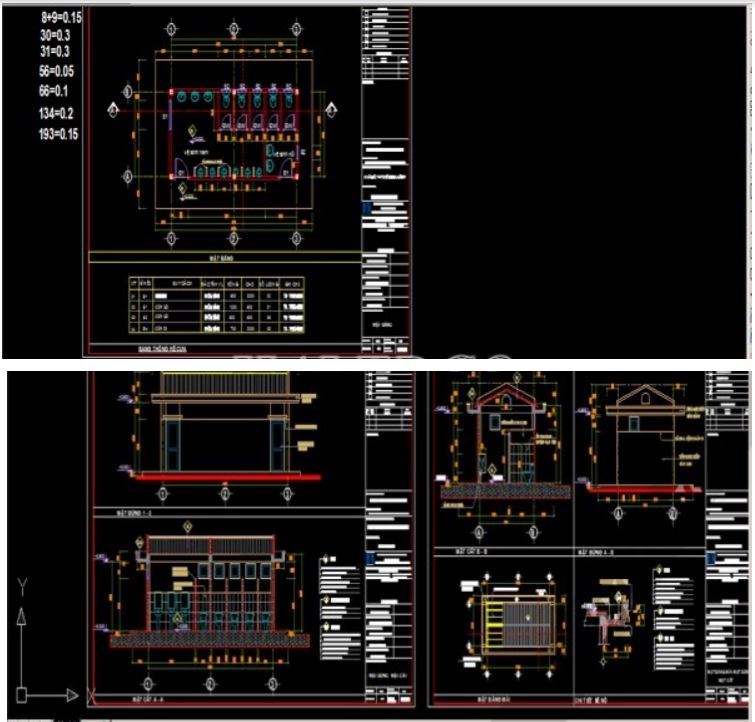

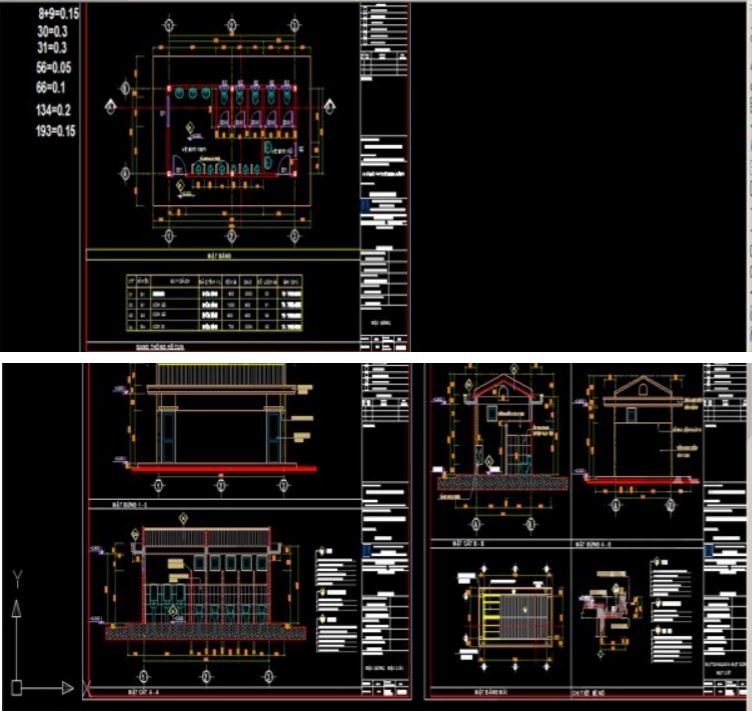

2.9 Mechanical Workshop Drawing Sample

- Requires careful load and space calculations

- Shows clear positioning of machinery, heavy equipment, crane systems

- Includes specific safety requirements

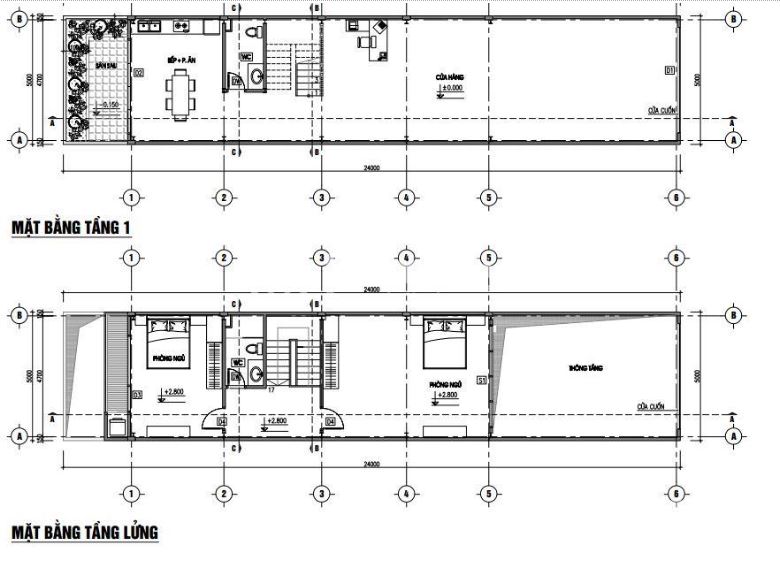

2.10 Two-Story Pre-Engineered Steel Building Drawing Sample

- Optimal solution for narrow spaces

- Two-story design maximizes floor area

- Shows detailed floor structure, stairs, load-bearing system and escape routes

2.11 10,000m2 Industrial Factory Drawing Sample

- Relatively simple design requiring spacious area to accommodate multiple equipment and machinery

- Suitable for small and medium enterprises

- Commonly used for goods storage, machinery storage or production equipment

- Major advantage in floor area provides solution for future production line expansion

2.12 20,000m2 Industrial Factory Drawing Sample

- Compared to 10,000m2 model, offers more spacious and airy environment

- Expands storage capacity

- Saves costs on raw material storage construction

- Suitable for small and medium enterprises with higher financial capacity

2.13 30,000m2 Industrial Factory Drawing Sample

- Suitable for small, medium and large enterprises investing in production processes or large warehouse storage

- Features large area with simple, spacious, and open design

- Helps businesses be more flexible in distributing production areas

2.14 60,000m2 Industrial Factory Drawing Sample

- Suitable for medium and large enterprises

- Features large structure and high load capacity

- Can store large volume of resources

- Businesses can divide production line positions into zones for easy management

2.15 100,000m2 Industrial Factory Drawing Sample

- Suitable for businesses in agriculture, forestry and fisheries sectors

- For enterprises with production line processes ranging from 20 billion to 100 billion VND

- Provides extremely large and open operating space

- Can accommodate production processes and warehousing

- However, large area means extremely high investment costs

- Businesses need proper cost accounting to avoid unnecessary waste

Each of these large-scale designs comes with comprehensive technical drawings showing structural details, zoning, and specific requirements for the intended industrial use. The designs progressively increase in complexity and specialized features as the scale increases.

3. Why are factory design drawings needed before construction?

Why do we need to carry out the design drawing process before constructing any building? Let's review the benefits that factory structural drawings provide:

- Ensures that the production facility's functionality meets the requirements and intended purposes set by the investor.

- Ensures the factory design complies with building codes and standards applicable to construction projects according to construction laws.

- Design drawings serve as the basis for monitoring and managing construction quality during the industrial factory construction process, as well as for inspection and acceptance testing before operation.

- Design drawings are also used for creating estimates, budgeting costs, and implementing construction according to estimates to ensure the project's economic efficiency.

4. Requirements of a factory construction design drawing

It is insufficient when a factory building is only shown on one drawing. Every structure and separated area needs both a general and a detailed drawing. The drawings need to be scientifically placed in the correct order, both vertically and horizontally. A complete pre-engineered steel building project requires these below drawings:

4.1 Architectural drawing

The architectural drawing is the overall drawing that shows how to distribute areas and plan to use the ground properly. Besides, the front elevation and cross-section are also demonstrated in this design drawing. The drawing has to show the height, width, and division ratios for areas in the factory building. The front elevation shows the general shape of the whole building; the cross-section will clearly show the details and crannies inside your pre-engineered factory.

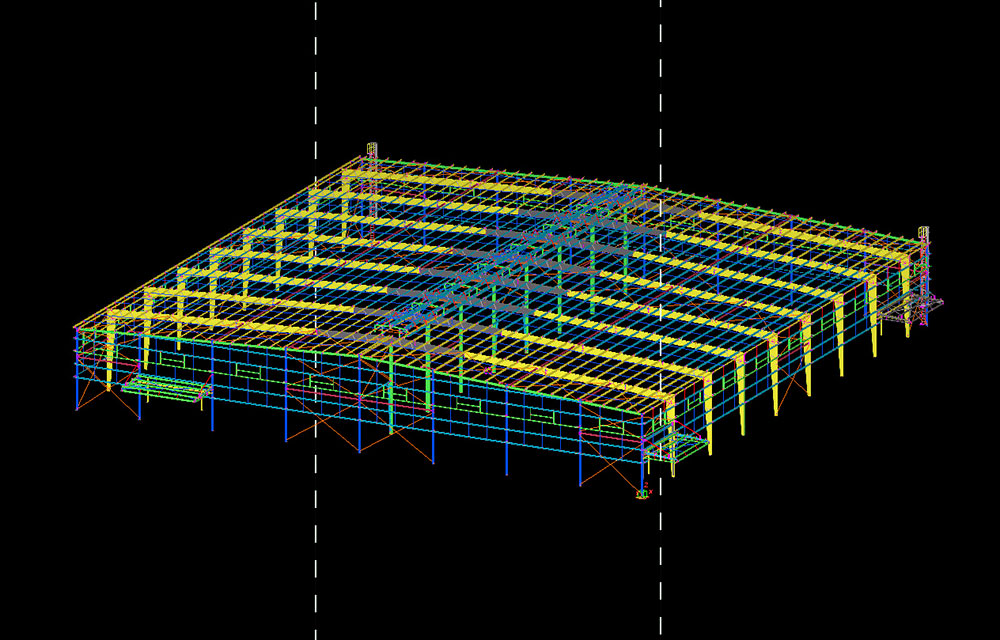

4.2 Drawing of steel structures

The steel structure drawing includes the details of the plan and the locations which are positioned accurately. Additionally, it comprises components of the foundation, column, beam, truss, steel columns, and the crossbars that need to be used. Besides, the entire frame making the general steel structure for the house is also shown on this drawing.

4.3 Drawing of electrical and lighting system

The lighting system is an integral part of a pre-engineered factory architecture or pre fabricated building architecture. This drawing demonstrates where to distribute the luminaires, the location of the sockets, how to carry out the electrical diagram, etc. It needs to make detailed and accurate drawings of the lighting system to ensure safety during the use of the factory.

4.4 Drawing of the water system

The water system also needs to be made a detailed drawing to complete the construction. It comprises a water supply system, water pipeline, drainage pipe, etc. Another thing that should be focused on is that the construction needs to be waterproof and robust enough to ensure load-bearing.

The drawing not only shows the shape of the structure but also shows the construction materials. Furthermore, it calculates how much money to invest in a project. Thus, the investment will reduce the incurred cost, and the construction will not miss any components.

5. Steps to design industrial factory drawings

Step 1: Basic Design The basic design drawings will include two parts: Written Description and Drawings.

Written Description Part:

- Description of construction site, technical infrastructure, and building design solutions

- Technology solutions to be used

- Architectural solutions

- Main structural solutions and technical systems

- Fire prevention and protection solutions according to state regulations

- Environmental protection solutions during construction

Drawing Part:

- Overall building drawings (elevations, horizontal views, cross-sections of the building)

- Production line drawings and technology diagrams

- Architectural solution drawings

- Main structural solution drawings

Step 2: Construction Drawing Design The design drawing documentation will include these main contents:

- Overall floor plan

- Technology diagram floor plan and accompanying auxiliary structures

- Building perspective and architectural documentation

- Frame and truss structure documentation

- Electrical and plumbing technical documentation

- Fire protection and wastewater treatment documentation

- Underground water tank

6. Important Considerations When Designing Industrial Factory Drawings

- Factory designers must thoroughly understand the use of materials.

- Parameters in the drawings must be calculated with absolute accuracy, ensuring compliance with construction regulations and laws.

- Drawings must fully demonstrate the factory's technical specifications, detailed steel material composition with standards sufficient for construction implementation.

- Drawings need to clearly show the layout of each area and the position of each piece of machinery.

- Businesses need to select a good construction contractor to whom they can entrust their complete building project.

Designing perfect factory design drawings and industrial building drawings is the first step in building a good factory. Industrial production facilities are the most important factor for a manufacturing business, therefore businesses should carefully consider before choosing a construction company to place their trust in. With 18 years of operation along with a team of experienced and passionate engineers and staff, BMB Steel is confident in delivering high-quality, unique, and distinctive pre-engineered steel building construction projects to our customers.