Prefabricated buildings have become a construction trend

- 1. What are prefabricated buildings

- 2. How are prefabricated buildings designed?

- 3. Prefabricated building application

- 4. Why prefabricated buildings become popular

- 5. The difference between prefabricated buildings and pre-engineered buildings

- 6. Some high-end prefabricated building models from only 2,000$

Prefabricated buildings are quickly becoming a favored option in construction due to their cost-effectiveness, speed, and sustainability. Starting at just $2,000, these structures offer an affordable solution, with rapid assembly and minimal environmental impact. Prefabrication provides a modern, efficient alternative to traditional construction methods, making it a rising trend in the global housing market.

1. What are prefabricated buildings

Prefabricated buildings (also known as assembly buildings or modular buildings) are buildings that are prefabricated from lightweight materials such as steel, wood, lightweight concrete at the factory and then transported to the construction site for assembly. The components of the prefabricated buildings are designed to meet specific requirements, assembled with bolts and screws, ensuring solidity and saving construction costs. Prefabricated buildings are soundproof, heat-insulated, and environmentally friendly, offering flexible solutions to meet customer needs.

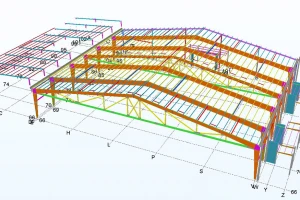

2. How are prefabricated buildings designed?

The structure of a prefabricated building is typically divided into 6 main parts: frame, partitions, roof, doors, ceiling and accessories.

2.1 Frame

The frame is made of C steel, galvanized steel box or CT3, forming the backbone of the buildings. The steel frame is pre-manufactured at the factory, designed into components for easy transportation and assembly. This frame is painted with anti-rust paint, galvanized or hot-dip to increase durability.

2.2 Partitions

The partition system consists of panels (corrugated iron + foam + corrugated iron), offering excellent soundproofing and heat insulation with a thickness of 50mm to 100mm, ensuring tightness and soundproofing for the interior space.

2.3 Roof

The roof is made of PU + PP corrugated iron or foam corrugated iron, with a thickness of 50mm to 100mm, providing good soundproofing, heat insulation and rust resistance.

2.4 Doors, windows

Use foam panel doors, aluminum glass or reinforced steel core plastic. Windows are usually aluminum glass or Korean plastic, ensuring strength and aesthetic appeal.

2.5 Ceiling

The ceiling can be made of plaster or plastic ceiling depending on project requirements.

2.6 Accessories

Accessories include connecting bolts, roof trim/flashing, eaves, gutters, and water pipe systems.

3. Prefabricated building application

Prefabricated buildings are gaining popularity across various industries due to their rapid construction, improved quality, and cost-efficiency. These structures are built using standardized designs and materials, making them versatile and suitable for many sectors.

Here are some applications of prefabricated buildings:

- Healthcare facilities, pharmacies

- Commercial retail spaces

- Hospitalities

- Educational facilities (schools, universities)

- Prefabricated offices

- Low-income housing solutions

4. Why prefabricated buildings become popular

4.1 Eco-Friendly

Prefabricated construction significantly reduces material waste by using recyclable materials and streamlined processes. Since it takes place in controlled factory environments, it minimizes environmental impact at the construction site while promoting energy efficiency through faster build times.

4.2 Safe

Building in a factory eliminates risks associated with weather, ground conditions, and other site hazards. Prefabricated materials, such as lightweight yet durable components, improve the structural safety of the final building.

4.3 Affordable

Prefabricated construction is more cost-effective than traditional methods, base on shorter build times and lower labor and material costs. Additionally, some prefab systems provide insulation benefits, which help reduce long-term energy bills.

4.4 Quick and efficient

With components produced offsite in controlled environments, on-site assembly time is significantly reduced. This process also avoids common delays caused by weather or resource shortages, speeding up project timelines and making it an ideal solution for addressing housing shortages.

4.5 Cost-effective

Prefabrication enables bulk-buying of materials and minimizes the need for on-site labor, resulting in lower overall costs. These savings can often be passed on to homebuyers, making housing more affordable.

4.6 Sustainable

Prefabrication supports sustainability by minimizing construction waste and creating energy-efficient buildings. These benefits continue long after construction is complete, leading to reduced energy consumption and lower operating costs.

4.7 Design flexibility

Contrary to the perception of rigid, cookie-cutter designs, modern prefabrication offers a high degree of design flexibility. Advanced technology allows for the customization of components to meet specific architectural needs, ensuring unique and functional designs without compromising efficiency.

5. The difference between prefabricated buildings and pre-engineered buildings

|

Prefabricated buildings |

Pre-engineered building |

|

|

Characteristic |

Manufactured as modules in the factory, the components are then transported to the construction site for final assembly. Prefabricated buildings often use lightweight materials such as foam corrugated iron, insulated panels, and light steel. |

The structure is built from steel components that are pre-fabricated at the factory and then transported to the construction site for erection. |

|

Application |

Often used for house, homestay, temporary office, coffee shop, weak condition ground. |

Often used for industrial building such as factory, warehouse, super market, showroom, or large scale building and high load-bearring demand. |

If you are interested in building pre-engineered steel buildings for industrial projects or factories, contact BMB Steel for detailed advice and construction support.

6. Some high-end prefabricated building models from only 2,000$

Prefabricated building with a small area of 15sqm

A 15m² prefabricated house is suitable for personal living space or office work. This model optimizes space while ensuring convenience and comfort, making it an ideal solution for those on a limited budget.

Compact Thai-roof prefabricated building

The Thai roof prefab house model combines traditional style with modern elements. Its design not only provides excellent insulation and heat resistance but also enhances aesthetics. This model is ideal for those who appreciate simplicity paired with sophistication.

Modern flat-roof prefabricated building

The flat roof design features a simple yet luxurious style, making it perfect for those who appreciate modernity and freshness in their living space.

Mobile prefabricated building 15sqm

The mobile prefabricated house model features a compact 15m² design that is easy to move and assemble. This flexible option is ideal for those seeking temporary living space or who frequently change locations.

Prefabricated container building

Prefabricated container houses offer a unique structure made from containers. This model is cost-effective and particularly well-suited for temporary offices at construction sites or for café setups.

Prefabricated homestay house with mini swimming pool

This is the ideal choice for those looking to start a tourism business. With a mini swimming pool and a modern, comfortable design, this house model becomes increasingly appealing, ensuring your guests feel at home.

Prefabricated house with wooden porch

This design offers a warm living space enhanced by a spacious wooden porch. The porch adds an aesthetic appeal and serves as an ideal spot to relax and enjoy the fresh air.

Prefabricated building for a small cafe

With an open layout, this house model features a cozy design, making it perfect for those looking to run a small café, helping to attract customers.

Prefabricated dome building

The dome roof is the standout feature of this house design, offering a unique and fresh aesthetic. This design is not only striking but also optimizes the interior space effectively.

Nhà lắp ghép kiểu mái vòm độc đáo

Prefabricated bungalow building

The bungalow-style prefabricated house offers a relaxing atmosphere that connects you with nature, allowing you to enjoy a peaceful life. This model is an ideal choice for resorts or homestays.

Office prefabricated building

Prefab office buildings are designed for modernity and comfort, making them ideal for small businesses or temporary offices. They offer a smart solution for anyone in need of a flexible workspace.

Prefabricated buildings offer an affordable, efficient, and eco-friendly solution for modern construction. Their growing popularity highlights their potential to revolutionize both residential and commercial building industries. BMB Steel hopes that the above information has provided valuable insights into prefabricated houses. If you need further advice or support, feel free to contact BMB Steel for assistance.