What is the best choice of textile factory design in manufacturing?

The textile industry on the market today is developed considerably. Therefore, more and more textile factories were born. At that time, the demand for factories and workshops to be designed and built increased. Thus, there are many factories with standard facilities. There are many models of textile factories designed with different sizes depending on the size of the company. Textile factories at the present time have been invested in ensuring their aesthetics and their functions. Let's find out in detail about the design of textile factories chosen by many businesses.

1. Special features when designing textile factories

Enterprises build textile factories because they are suitable for large-volume production of products which have many advantages over conventional garment factories.

- The business purpose when designing a textile factory is because of mass production and the need for large space.

- Creating high working efficiency saves time and manpower because it can accommodate large industrial textile machines.

- Designing a textile factory also helps reduce pressure on the cost of goods sold for businesses.

- Designing a textile factory with a high degree of professionalism and optimal support for large orders. Besides, there are not many human resources to create a favorable working environment for workers.

- The design of a textile factory will be cooled by pressure.

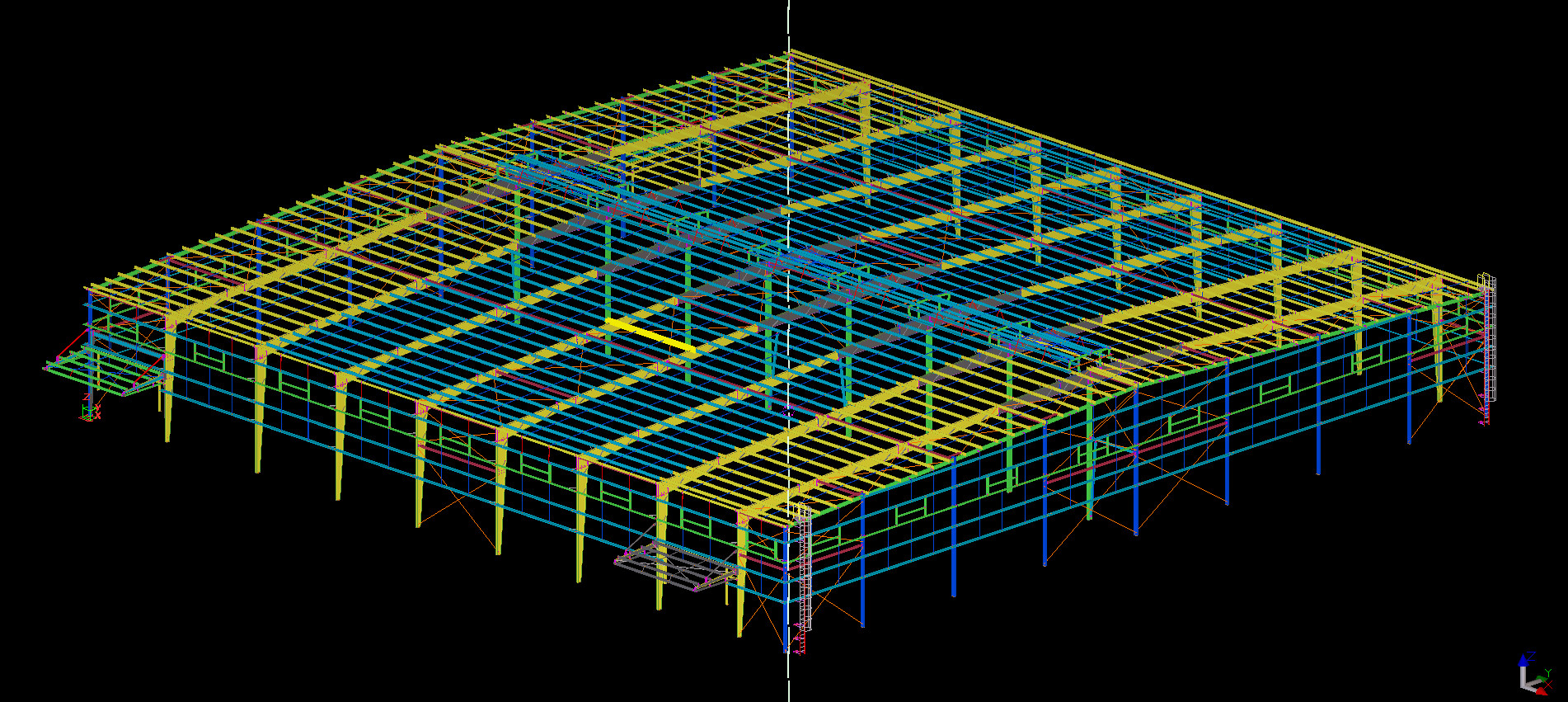

2. Structure of textile factory

Textile factory design includes the following structures:

Construction of foundation and floor: Textile factory will build with single foundation or pile foundation and pour surrounding girder. The background of the textile factory has a thickness of 150-200mm, besides the elastic background design. These measures help to reduce the load from the compressing superstructure.

Structure of trusses and purlins of textile factories: To optimize the structure, columns and trusses need to choose the appropriate design. Today's textile factories often use composite steel frames in the shape of the letter I. However, it can also be replaced by foundation bolts linked to the factory column and C and Z purlins.

Roofing for textile factories: Regarding roofing, we will choose quality assurance combined with suitable insulation materials, ensuring the optimal working environment for workers. In parallel, you should also select lightweight roofing sheets to reduce the load on other structures.

The panel of the textile factory will usually have a considerable height of about 5 to 7m. That creates a height with good ventilation. Moreover, the arrangement of the mezzanine floor will be more straightforward. The back panel will help businesses or investors change, expand the space, and use it flexibly during use.

3. Advantages of a textile factory

- Textile factories have a long service life, stable operation, and flexible use.

- Easy to design and install, save investment costs, and operate quickly and effectively.

- Reducing the amount of gas emissions into the environment when the hot gas emissions are low.

- The textile factory has an automatic and safe operating system.

- During use, the simple structure makes it easy to repair, renovate and upgrade.

- Large comfortable working space for workers and production process.

4. Enterprise, which is suitable for choosing a textile factory

Textile and garment enterprises, depending on the orders they receive, select the size of the factory. Small, medium and large enterprises will choose a workshop with the corresponding space size for the production line as well as space for workers to work efficiently.

You should choose a factory design with many sizes, such as 10,000m2, 150,000m2, and 300,000m2 depending on the purpose of building a reasonable factory design to optimize the area in production.

5. Things businesses need to keep in mind when choosing to build a textile factory

When designing a textile factory, you need to pay attention to the following:

- Choose the construction design of the foundation suitable for the factory scale.

- Fully prepare all soundproofing, ventilation, cover, etc.

- Prepare a plan for the cost of designing and building a garment factory.

- Choose a reputable construction company with high-quality works. From the very beginning, choosing an unprofessional construction team will affect the construction process and cause unnecessary business losses.

- Make detailed design drawings of garment factories to avoid having to revise many times, leading to increased investment costs.

6. Samples of textile factories

Detailed information about the textile factory has been provided in detail above; hopefully, it will be helpful information for businesses to make the right choice as well as get the best textile factory to bring high business efficiency during use.