Things to know about small industrial factory drawing

Are you a business looking to build a factory with an area ranging from 200m2 to 1,000m2? Are you looking for a small industrial factory design drawing? This article will be the optimal solution for you because we will introduce you to some popular small industrial factory drawings in the article below.

1. Advantages of building a small industrial factory

Why is the type of small industrial factory such as the 300m2, 500m2, 800m2 factory models becoming popular recently? Let's find out some advantages of a small industrial factory!

- Space saving: Small industrial workshops have an area that is not too large, which does not take up much land space. However, it is also suitable for use with many purposes such as production workshops, processing workshops, installation workshops, garages, etc. Therefore, this type of factory will be suitable for companies, small and medium enterprises - companies that do not have a large budget to spend on factories.

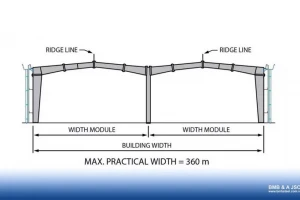

- Small industrial workshops can be installed on many grounds: Because of the small size, the requirements for the ground, the space requirements of this type of workshop will not be complicated. If the business owner builds a factory with a pre-engineered steel frame, the factory can also be built on weak and uneven terrain.

- Cost savings: Compared with large factories, factories under 1,000m2 will save costs for businesses. Because of the small area, of course, the costs for design, construction and construction are also minimized. Businesses can eliminate unnecessary expenses and use that money for business activities. In addition, small factories also help investment owners save on annual operating and maintenance costs.

2. Some drawings of small industrial factories

On the market today, there are many small, beautiful and convenient factory models. Below are drawings of some of the most popular factory models today, such as:

2.1 Factory with an area of 300m2

The 300m2 factory will have a small area and simple construction conditions, suitable for individual or household businesses with low cost, not requiring too much space, area or facilities. Newly established businesses can also choose this factory model to save space, area and cost.

2.2 Factory model with an area of 500m2

Another choice for small businesses is the factory model with an area of 500m2. This type of workshop is suitable for storing goods, installing machinery and equipment or processing workshops. The factory with an area of 500m2 is also easy to install, saving time and construction costs for businesses.

2.3 Factory model with an area of 800m2

Medium-scale manufacturing enterprises or goods service enterprises can choose a factory model with an area of 800m2. The larger area helps to increase the usable space, this factory can also be divided into several zones with separate tasks, making it easy for businesses to manage the production process.

2.4 Factory sample with an area of 1,000m2

If you want to have more storage space and production space, you can consider a factory model with an area of 1,000m2. This factory model is suitable for warehouses, production workshops, installation workshops, etc. With this area, the factory looks quite large so that businesses can be more comfortable in the distribution of production areas.

3. Some notes when designing small industrial factories

Here, BMB Steel would like to share with customers some factors to pay attention to in the design process of the factory so that the construction process takes place most effectively.

3.1 Identify the main materials used in the construction of the factory

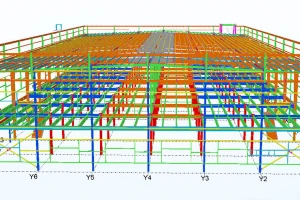

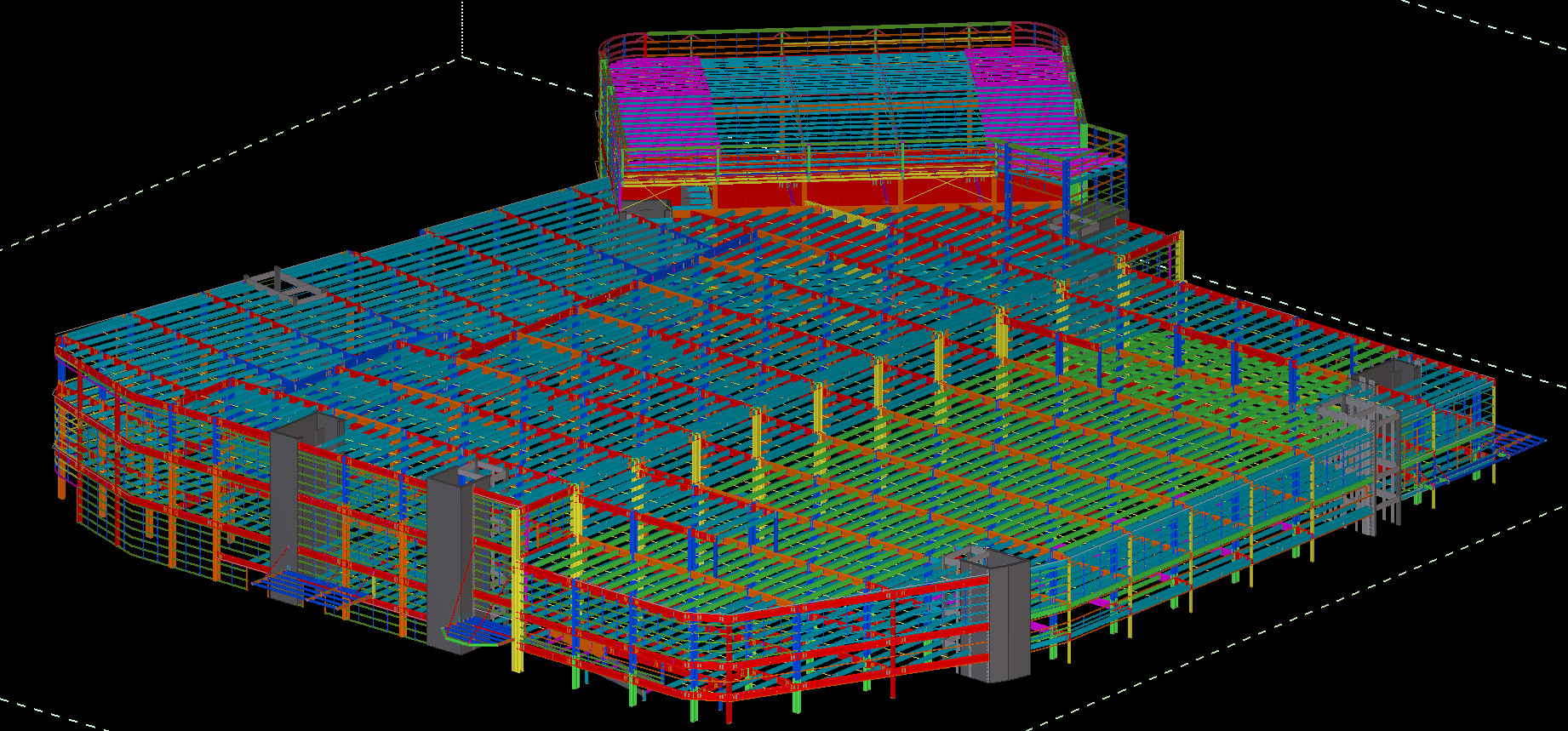

The first step when designing construction drawings is to choose the main materials that make up the factory. Construction materials must be sturdy and suitable for business purposes. Enterprises can use traditional materials such as bricks, sand, cement, concrete or modern materials such as pre-engineered steel frames, unburnt bricks, etc to make the main building materials.

3.2 Make a plan to deal with problems arising during the construction process

There are many problems that can arise during construction that seriously affect the factory. Therefore, from the first steps such as designing drawings, businesses need to anticipate and provide solutions for possible problems related to the foundation, reinforcement, foundation, and machinery. Some problems that may occur are the deformed structural system, collapse of the building, lack of capital, lack of raw materials, fire, explosion, etc.

3.3 Ensuring labor safety for employees

Employee safety must be a top priority. During the construction process, enterprises should pay attention to install enough labor protection equipment to avoid unfortunate events. In addition, enterprises must place warning signs for labor in dangerous areas, prone to accidents.

3.4 Ensuring environmental quality

Environmental protection when building factories is also a notable issue of investors. During the construction process, enterprises must take measures to handle excess raw materials and construction waste to limit environmental pollution. Enterprises must comply with regulations on environmental protection in construction work according to Circular No. 02/2018/TT-BXD.

3.5 Building a suitable lighting system for the factory

When designing a factory drawing, the enterprise will design the lighting system inside it. The factory projection system will need to be selected and calculated appropriately, because otherwise, it may cause waste and inefficient production performance. For small factory models, small-capacity LED factory lights should be used such as 50W LED factory lights or 100W LED factory lights.

Above is all the information about the construction and design of small industrial factories that BMB Steel wants to share with customers. We hope that the information we provide will help you in the process of building your factory.