Professional pre-engineered steel building construction process

Construction of pre-engineered steel factories is gradually replacing traditional reinforced concrete factories. Hence, how will a pre-engineered steel building construction process take place? Let's learn more with BMB Steel through the following article.

1. The advantages of the construction of pre-engineered steel buildings

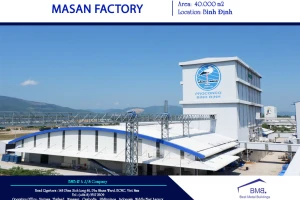

Pre-engineered factory or pre-engineered steel frame factory is a type of workshop that is mainly composed of pre-engineered steel frames and installed according to available designed drawings.

The construction of pre-engineered steel frame factories has many advantages compared to reinforced concrete factory such as:

- Construction of pre-engineered steel buildings helps to optimize costs for businesses: According to some surveys, building factories with pre-engineered steel frames saves 30% of costs compared to building traditional reinforced concrete houses. Pre-engineered steel buildings help save material costs in areas with low bearing capacity.

- Faster construction time of pre-engineered steel buildings: The structural components that make up the steel buildings are manufactured and then brought to the erection site. The process of manufacturing components and erection involves a team of engineers with many years of experience and the support of modern machinery to help the work be completed more quickly.

- Steel structure is easy to create flexibility in design, investors can unleash their creativity to create modern, impressive and unique pre-engineered steel buildings according to their expectations. The steel frames are linked by bolts, so they can be disassembled and reused if desired, expanding or upgrading the building is also easier than in a reinforced concrete factory.

- Using a steel frame to reduce the load on the foundation structure makes pre-engineered steel buildings suitable for construction on many sites, including weak soils or frequent small earthquakes.

2. Construction process of pre-engineered steel buildings

The construction process of pre-engineered steel buildings normally goes through 3 stages: Design, manufacture of components, construction and erection of pre-engineered steel buildings. Here, let's dive into each stage of the pre-engineered steel building construction process!

2.1 Phase 1: Design of pre-engineered steel buildings

This is an indispensible stage in the construction process of pre-engineered steel buildings. During this phase, architects will calculate the required specifications and survey construction sites to complete architectural drawings. The design steps of pre-engineered steel buildings include:

- Architects survey the site and offer design solutions, explain to investors and then propose the most optimal solution.

- Complete construction drawing design documents, including: architectural drawings, structural drawings, electrical network drawings, water drawings, etc. The drawings must be absolutely accurate in size, detail, quantity and technical requirements. Errors in the drawings will lead to misunderstandings by the construction worker and affect the quality of the workshop.

2.2 Stage 2: Processing pre-engineered steel building structures

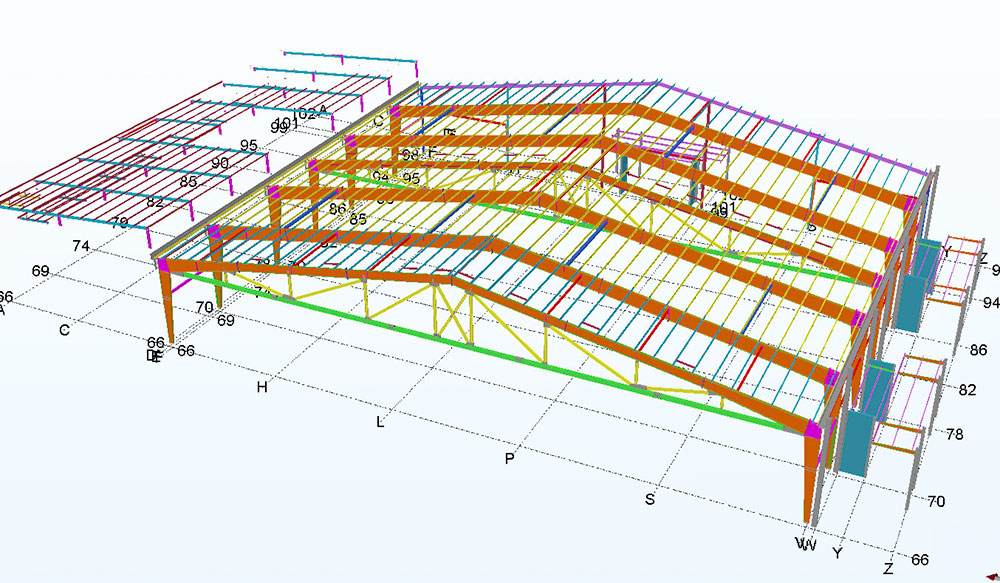

The process of processing components must be carried out in workshops with modern machinery systems and the quality of components must be carefully checked. The components processing steps include: receiving materials, cutting, combining, welding, surface cleaning, and painting. After the processing is complete, the components will gather at the yard to check the quantity, size and quality before being stamped and transported to the assembly place.

2.3 Stage 3: The process of erecting pre-engineered steel buildings

The followings are the main stages of a pre-engineered steel building erection process:

- Fabrication and erection of foundation bolts for factories.

- Fabrication and erection of the main frame system of the factory: erection of hard locking booths, installation of truss frames, construction of locking trusses, erection of trusses and purlins, installation of anti-purlins. After the installation is complete, it is necessary to re-calibrate the entire main frame system to ensure the stability of the work.

- Carrying out pulling corrugated iron and roofing: pulling corrugated iron to the roof, roofing corrugated iron, installing details of wall purlins, corrugated iron, gutters.

- Installing doors and other accessories for the factory.

- Conducting re-inspection of the work, repaint and repair scratched components, complete and hand over the work.

3. Notes when constructing pre-engineered steel buildings

Here are some notes for businesses and construction companies when constructing pre-engineered steel buildings:

- During the construction process, it is significant to pay attention to the foundation construction. When building works on soft and muddy soil, it is necessary to have measures to strengthen the foundation firmly such as pressing piles.

- If building a factory on soft ground or using a lot of moving vehicles that cause vibrations that affect the bearing capacity of the factory, the weight of the steel frames should be minimized as possible to reduce the impact on the foundation.

- It is recommended to use smartboard cement panels with a thickness of 10mm to 20mm to make partitions that help increase the solidity and bearing capacity for the wall covering the prefabricated house in the future. Avoid placing goods and machinery close to the partition to avoid direct impact on the partition.

- Workers performing the erection must ensure alertness and concentration during the working process. They should be fully equipped with safety protective equipment.

- When there is bad weather, strong wind or storm, the construction must be stopped.

- To ensure the safe construction of pre-engineered steel buildings, the first step to do is to install a rigid bracing compartment. After completing the rigid bracing, the contractor must check and align the accuracy of the frame, then continue to install other frames with the main bracing frame. It is necessary to install at least 50% of the purlins of each compartment, preferably 100% of the purlins.

BMB Steel hopes that the article has provided customers with necessary information about the typical pre-engineered steel building construction process.