Primary framing options in pre-engineered steel building systems

Pre-engineered steel buildings have gained popularity in the construction industry due to their numerous benefits. One of the key components that contribute to the structural integrity and functionality of these buildings is the primary framing system. The primary framing system forms the skeleton of the structure, providing support and stability. In this article, we will explore the primary framing options commonly used in pre-engineered steel building systems.

1. A brief introduction to the pre-engineered steel building concept

Pre-engineered steel buildings refer to structures that are designed, fabricated, and assembled using standardized components and methods before being transported to the construction site. These buildings are engineered to meet specific requirements and are manufactured off-site, allowing for faster and more efficient construction processes.

The components of pre-engineered steel buildings, such as columns, beams, and panels, are fabricated in a factory and then assembled on-site. This construction method provides numerous advantages, including cost-effectiveness, customization options, durability, and compliance with building codes and regulations. Pre-engineered steel buildings have gained popularity in various industries to meet the unique needs of different applications.

2. Primary framing options in pre-engineered steel building systems

The primary framing system is a crucial component in pre-engineered steel building systems. Clearspan rigid frames, modular frames, single-slope frames, lean-to frames, and multi-span frames are among the primary framing options available. Each option offers unique advantages and is suited for specific building requirements.

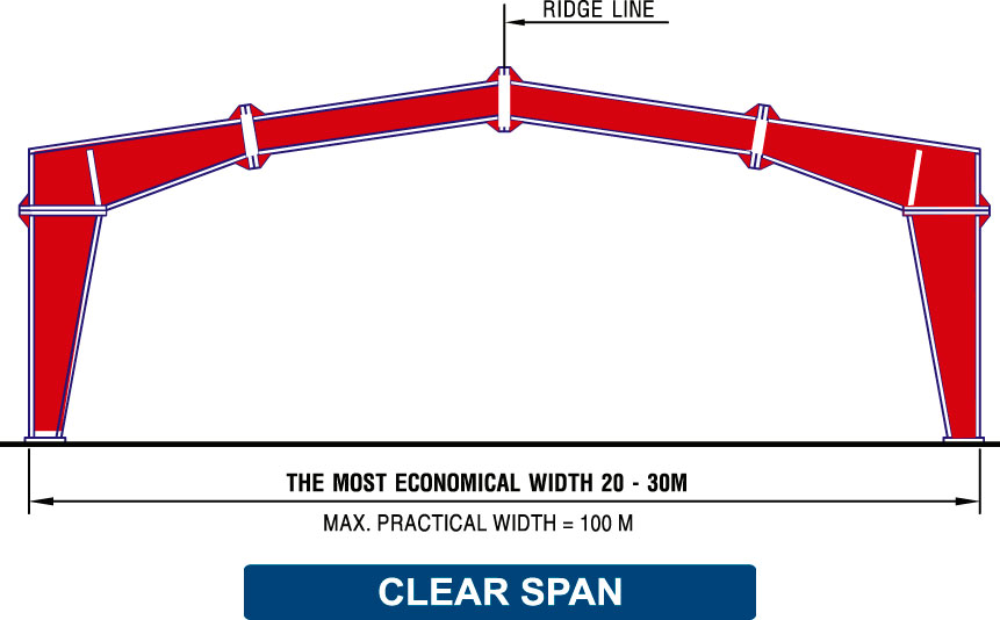

2.1 Clear-span frames

Clearspan rigid frames are a popular choice for pre-engineered steel buildings that require spacious interiors without the hindrance of interior columns. These frames consist of columns and rafters connected by rigid moment connections. With clearspan frames, there are no obstructions, allowing for maximum flexibility in utilizing the interior space. This makes them well-suited for applications such as warehouses, manufacturing facilities, and sports arenas.

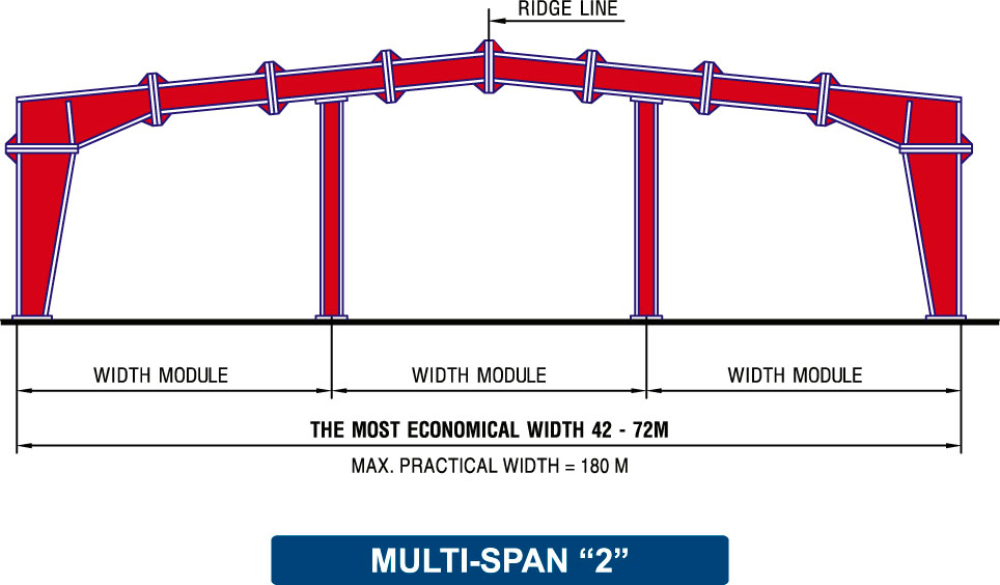

2.2 Multi-span frames

Multi-span frames consist of multiple bays with intermediate columns and beams, providing structural support and flexibility. These intermediate columns and beams are strategically placed to distribute the load and provide structural integrity. The spans between the columns can vary in length based on design requirements and the desired layout of the building. Multi-span frames are suitable for applications where versatility and efficient use of interior space are essential, such as warehouses, distribution centers, and manufacturing facilities.

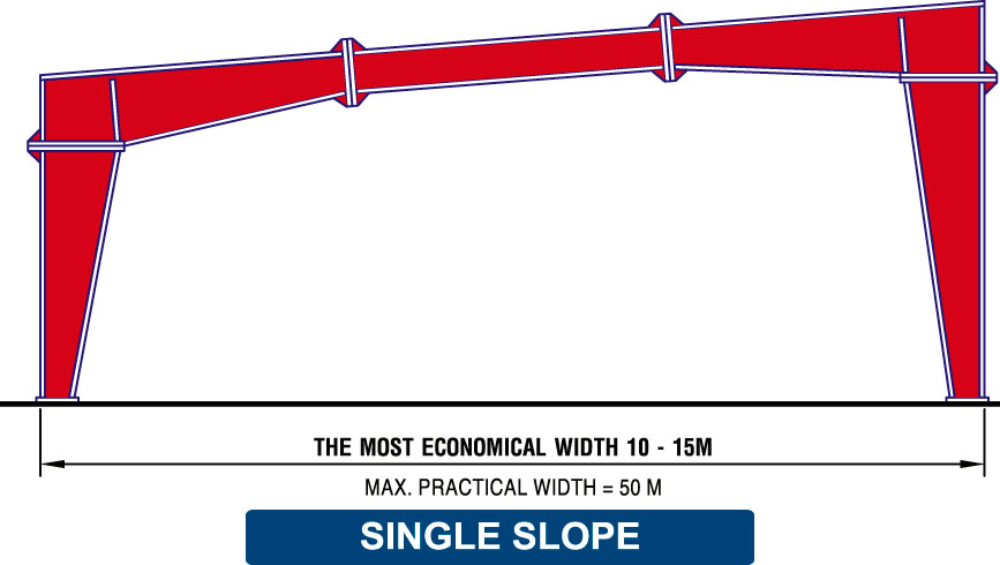

2.3 Single-slope frames

Single-slope frames are designed with a sloped roof, making them suitable for buildings that require efficient rainwater drainage or a distinct architectural aesthetic. These frames consist of tapered or straight columns and rafters, creating a single-slope roof. Single-slope frames find application in retail facilities, car dealerships, and agricultural buildings.

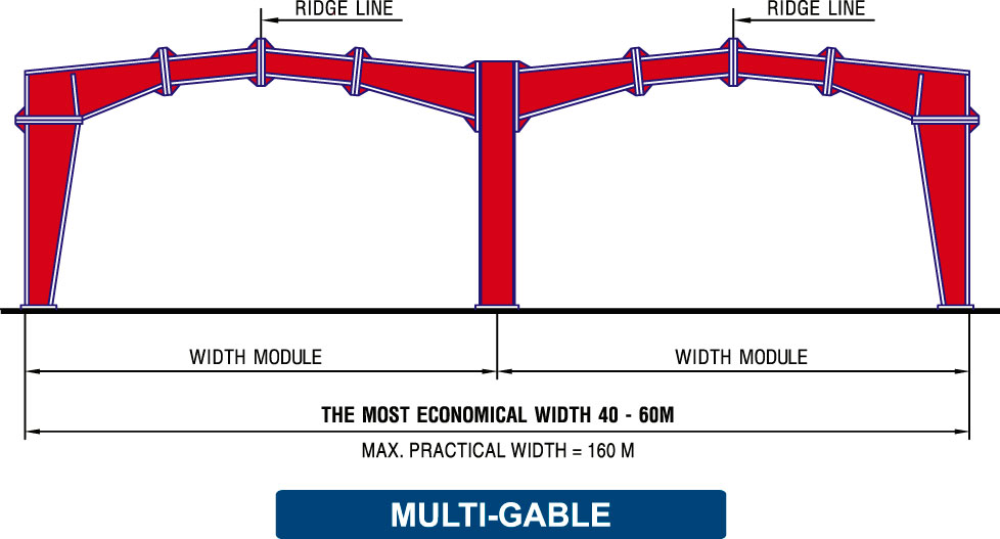

2.4 Multi-gable frames

Multi-gable frames are utilized to build two or more gable buildings sharing common sidewall columns. Multi-gable frames are suitable for large buildings to reduce ridge height. By sharing common sidewall columns, these buildings provide a seamless movement across the width of the structure and allow efficient utilization of materials. This framing option is well-suited for buildings that require architectural interest, such as churches, community centers, and recreational facilities.

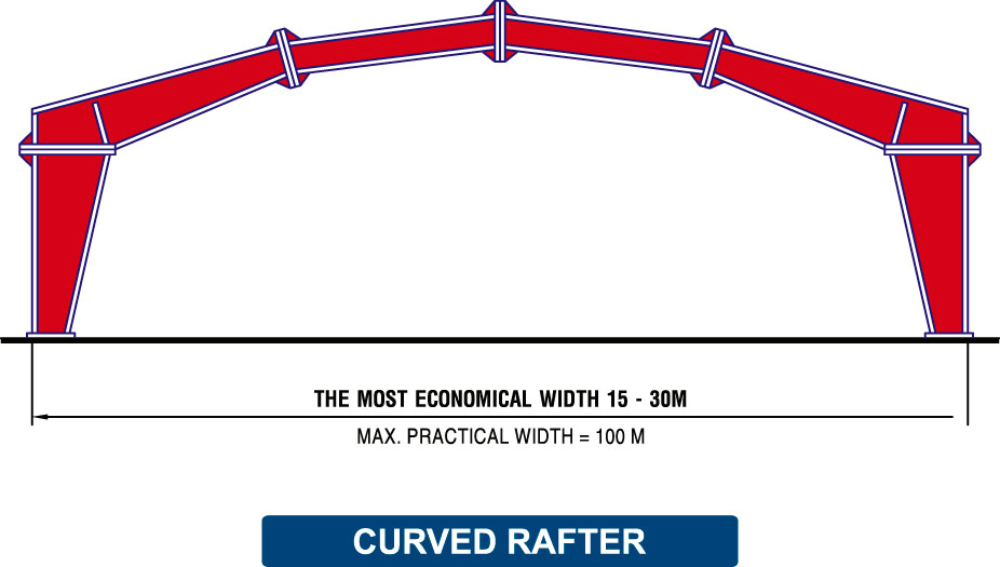

2.5 Curved-rafter frames

Curved rafter frames offer a unique design option in pre-engineered steel buildings. These frames feature curved roof rafters, providing an elegant and distinctive architectural appeal. Curved rafter frames are often employed in structures such as sports facilities, convention centers, and museums, where a visually striking design is desired.

3. Factors to consider when choosing primary framing options in pre-engineered steel buildings

Choosing the right primary framing option in a pre-engineered steel building system is crucial for ensuring structural integrity, functionality, and cost-effectiveness. Here are some key factors to consider when making this decision:

- Building purpose and design requirements: Understand the purpose of the building and its design requirements. Consider factors such as the intended use, desired interior space, load-bearing capacity, and architectural aesthetics. For example, warehouses may benefit from clearspan rigid frames to maximize storage space, while commercial buildings may require multi-span frames for flexible layouts.

- Span requirements: Evaluate the span requirements of the building. Determine the desired width and length of the interior space, taking into account any limitations or restrictions. Consider the need for large, uninterrupted areas or multiple compartments.

- Building height: Consider the height of the building. Tall buildings may require additional considerations for structural stability and lateral support. Consult with structural engineers to determine the appropriate primary framing option that can handle the vertical loads and provide necessary resistance to wind and seismic forces.

- Budget and cost considerations: Evaluate the budget available for the project. Different primary framing options have varying costs associated with materials, fabrication, and installation. Consider the long-term cost implications, including maintenance and operational expenses.

- Local building codes and regulations: Ensure compliance with local building codes and regulations. Each framing option must meet the required standards for structural safety and performance.

- Future expansion and flexibility: Consider the potential need for future expansion or modifications to the building. Evaluate the adaptability and flexibility of each primary framing option to accommodate future changes. Certain options, such as multi-span frames, may offer greater flexibility for future expansion or reconfiguration.

- Construction timelines: Assess the desired construction timelines and project schedule.

By carefully evaluating these factors and seeking professional guidance, you can choose the primary framing option that best meets your needs in terms of structural integrity, functionality, aesthetics, and cost-effectiveness.

Above is some information regarding primary framing options in pre-engineered steel building systems. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.