Factory construction: A complete guide to process and unit Prices (2026)

- 1. What is an building factory construction?

- 2. Basic requirements in constructing factory construction

- 3. Advantages of building factory construction

- 4. Process of building factory construction

- 5. Criteria to follow when constructing and assembling workshops

- 6. Factors affecting the cost of building factory construction

- 7. Price list for building factory construction 2026

- 8. Some notes in the industrial factory construction process

- 9. BMB Steel - International standard industrial factory construction company

Building factory construction is one of the important steps to ensure sustainable development for manufacturing enterprises. Factory construction are not only places of production but also factors that directly affect productivity and business efficiency. In this article, BMB Steel will detail the process of building factory construction from the planning, design, construction to completion phases.

1. What is an building factory construction?

Building factory construction is the process of planning, designing, and constructing infrastructure for production in areas such as processing, assembly, industrial manufacturing, or storage warehouses.

This type of factory construction is large in size, requires high load-bearing design, and must meet safety, quality, and production efficiency standards.

Factory construction are usually built with various structural types, including prefabricated steel factory and reinforced concrete workshops. Depending on production goals and types of businesses, investors can choose the suitable construction option.

2. Basic requirements in constructing factory construction

2.1 Designing factories to meet production goals

The design of the factory is an important step in the construction process. The design document must suit the specific characteristics of the enterprise's activities and usage purpose.

Based on specific factors such as the type of products, scale of investment,... careful selection of construction materials is required to ensure effective construction. Currently, factories are typically categorized into two main types: concrete factories and prefabricated steel factories.

2.2 Requirements for factory design drawings

Design drawings need to cover elements such as frames, reinforced concrete, the overall structure of the factory, floor layout diagrams, and architectural details.

Additionally, the construction process must comply with production standards, occupational safety, and construction regulations to ensure effectiveness and safety in use.

2.3 Note technology requirements

The design of the factory must consider factors like load, geological conditions, and construction costs to choose suitable methods, optimizing the investment budget.

3. Advantages of building factory construction

Building factory construction brings significant benefits, helping enterprises save costs and improve production efficiency. Below are some notable advantages:

- Cost savings: Factory construction are built from sustainable and cost-effective materials, such as prefabricated steel and reinforced concrete, helping to lower construction and maintenance costs.

- Increased production efficiency: With spacious space, designed to accommodate the production line, factory construction help enterprises optimize production and storage processes.

- Fast construction time: Thanks to modern construction technologies and standardized construction processes, factory construction can be completed in a short time, minimizing production downtime.

- Design flexibility: Factory construction can be easily adjusted and expanded when necessary, quickly adapting to changes in production.

- Aesthetic and modern: Not only meeting functional requirements, today’s factory construction are also designed with high aesthetic value, creating a professional image for the enterprise.

4. Process of building factory construction

The process of building factory construction requires close coordination between many phases, from planning to construction implementation. Below are the basic steps in the process of building factory construction.

To ensure that the building of factory construction meets technical and safety standards as required, enterprises need to thoroughly understand each step in the factory construction process. This process can be divided into three main stages:

- Designing the factory

- Preparation for construction

- Constructing the factory

The construction of factory construction requires thorough preparation and compliance with specific regulations. Below are detailed steps to implement construction to ensure progress and optimize costs.

4.1. Designing the factory

Step 1: Survey and develop construction plan

Before starting the construction, the contractor needs to survey the actual site and ground of the project to propose the optimal design and construction plan. The plans should include:

- Technical infrastructure: Propose solutions suitable for the type of workshop, warehouse, or factory to ensure efficiency and reasonability.

- Architectural requirements: For items like offices or guard posts, design plans must meet aesthetic and functional requirements.

- Environment and fire prevention (fire safety): Ensure compliance with regulations on environmental protection and fire safety as required by industrial or industrial clusters.

- Foundation structure: Choose suitable foundation design based on geological conditions at the construction site.

The survey process must pay special attention to factors:

- Environmental regulations and fire safety in the area.

- Geological characteristics to ensure a solid foundation.

Step 2: Design preliminary plan

After understanding the investor's requirements and the conditions at the construction site, the team of architects and engineers will proceed to create preliminary drawings, including:

- Overall planning layout drawings

- Detailed drawings for each item

- 3D perspective drawings

These drawings help investors have a comprehensive view of the project, clearly presenting factors such as:

- Construction boundaries and density.

- Internal roads, greenery areas.

- Fire safety and emergency exits.

- Necessary equipment, spaces for workshop activities.

Step 3: Design working construction drawings

After agreeing on the preliminary plan, the next step is to design detailed working construction drawings, including:

- Foundation structure suitable for ground conditions.

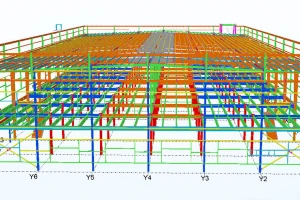

- Prefabricated steel frame and joints.

- Material specifications and electrical and mechanical system (M&E) drawings.

- Specific fire safety for each item.

The necessary items include:

- Production workshops, warehouses.

- Offices, canteens, garages, guard houses.

- Underground tanks, power stations, gates, fences.

In this phase, the contractor will:

- Apply for construction and fire safety permits.

- Create a detailed cost estimate (BOQ) including volumes and specific tasks for each item.

- The design documents and the cost estimate will serve as a basis for acceptance and verification of completed work volumes.

This is also the phase of creating detailed estimates of construction costs and subsequent acceptance works.

4.2. Preparation for construction

The preparation phase is a crucial step in ensuring the schedule and quality of the project. This process includes the following steps:

Step 1: Develop detailed construction methods and schedules

The construction team needs to establish a detailed plan for construction methods, including steps like organizing the site, setting foundation bolts, and preparing materials. Additionally, the construction schedule must be clearly established, dividing tasks by item and specific time.

Step 2: Prepare materials and equipment

The contractor will prepare materials, including steel frames, roofing sheets, partitions, and electrical and mechanical equipment. These materials need to be thoroughly quality-checked before use.

Step 3: Ensure site and legal compliance

Before proceeding with construction, the contractor needs to ensure that the construction site is fully prepared, including cleaning the land, defining pathways for equipment and materials. Meanwhile, the contractor also needs to finalize related legal procedures, including construction permits and approvals for fire safety items.

4.3. Constructing the factory

After completing the preparation work, the construction process will be carried out. The process of constructing factory construction typically includes four main phases:

Phase 1: Constructing the workshop's foundation

The foundation is a key element determining the durability and safety of the structure. Depending on geological conditions and load-bearing requirements, the contractor will choose a suitable foundation solution, such as pile foundations or individual foundations. Before pouring the concrete foundation, the contractor needs to place foundation bolts (anchor bolts) to connect with the steel column system of the workshop.

Phase 2: Processing prefabricated steel frames at the factory

To ensure progress, steel frame components will be processed at the factory while the foundation is being constructed. This helps to ensure quality and technical accuracy before assembly at the site.

Phase 3: Installing the steel frame at the site

Once the concrete foundation has reached sufficient hardness, the steel components will be transported to the construction site and installed. The process of assembling the steel frame requires high accuracy and must be performed according to strict safety procedures to ensure the quality of the structure.

Phase 4: Completing the workshop and installing the technical system

After completing the steel frame assembly, finishing work such as roofing, building enclosing walls, and installing electrical and mechanical systems will be carried out. Technical systems such as electricity, water, and fire safety must be installed and thoroughly checked before handing over the project.

4.4. Inspection and acceptance

After the project is completed, the contractor will conduct inspections of all items to ensure quality according to design requirements. The acceptance process will involve the participation of the investor and authorities, including:

- Structural inspection: Ensure the durability and safety of the steel frame, foundation, and related items.

- Technical system inspection: Ensure the electrical and mechanical systems, fire safety function as required.

- Finishing inspection: Assess the quality of finishing items such as roofing, surrounding walls, and interior equipment.

After a successful acceptance, the project will be handed over to the investor for use.

5. Criteria to follow when constructing and assembling workshops

To ensure quality and effective use, the construction of factory construction needs to comply with strict standards. Below are important criteria in the construction process:

5.1. Ensure a solid foundation

The foundation is a determining factor for the durability and safety of the factory. If the construction area has a solid foundation, the workshop will be easier to construct. However, in case of weak soil foundation, appropriate reinforcement measures should be used.

Before construction, the investor needs to thoroughly survey the land, including:

- Land area and quality.

- Related factors such as infrastructure and conditions in the surrounding area.

5.2. Ensure the frame is solid and work safety

The phase of assembling the workshop frame is an important step in shaping the structure of the project. To ensure safety and quality:

- The workshop frame must be designed and built solidly and durably.

- Provide sufficient personal protective equipment (PPE) for workers to minimize risks during construction.

- The execution process needs to be meticulous and comply with safety standards.

5.3. Meet infrastructure principles when constructing workshops

Standards regarding environment and labor safety:

- Ensure a safe working environment, minimize noise and dust.

- Correctly collect and treat waste.

- Monitor safety throughout the construction process.

Install appropriate equipment:

- Equipment and means in the workshop must meet the operation scale.

- Logical layout to ensure smooth production, hygiene, and easy maintenance.

Technical and electrical systems:

- Ensure a stable power supply suitable for the operational needs of the workshop.

- The technical system must be thoroughly checked to support effective production.

Water supply and drainage systems:

- Design an effective supply, drainage, and waste treatment system.

- Ensure no contamination of the surrounding environment (land, air, water).

- Following these criteria not only helps the workshop achieve high quality but also ensures a safe and sustainable working environment.

6. Factors affecting the cost of building factory construction

The cost of building factory construction is not fixed and can vary depending on many factors. Below are some important factors affecting the total cost:

- Scale and area: Large-scale projects will require more materials and efforts, thus leading to higher costs.

- Type of construction material: Choosing construction materials directly affects the costs. Using high-quality materials will increase costs but ensure quality and long-lasting durability.

- Construction location: Areas with complex geological conditions increase foundation costs or distance from the center will increase transportation and labor costs.

- Construction time: Projects needed to be completed in a short time will require additional costs for hiring more labor and equipment.

7. Price list for building factory construction 2026

Below is a reference price list for services of building factory construction in 2026, depending on the scale and type of construction.

|

Construction items and workshop services |

Unit price (VNĐ) |

|

Construction permit for workshops |

45,000,000 – 200,000,000/file |

|

Design of prefabricated workshops |

25,000 – 80,000/m² |

|

Construction of prefabricated workshops |

830,000 – 1,400,000/m² |

|

Installation of transformer stations for production workshops (from 50KVA to 2500KVA) |

500,000,000 – 1,400,000,000/station |

|

Installation of electrical systems for prefabricated workshops (including lighting, cooling, mechanical electricity,...) |

25,000 – 50,000/m² |

|

Installation of fire protection systems for prefabricated workshops |

12,000 – 17,000/m² |

|

Construction of crane systems for prefabricated steel workshops |

130,000,000 – 550,000,000/crane |

|

Installation of elevator systems for prefabricated workshops |

Contact for detailed pricing |

|

Completion of prefabricated workshop construction |

25,000,000 – 200,000,000/file |

Note: Prices can change depending on actual construction conditions and specific requirements of the project.

8. Some notes in the industrial factory construction process

The process of building factory construction needs to be carried out carefully to ensure quality, safety, and effectiveness. Here are important notes in each phase:

8.1. Planning and design

Site selection and preparation: Choose land with reasonable planning, convenient transportation, and ensure the load-bearing capacity of the structure.

Detailed technical plan: Parameters such as structure, foundation, materials, and construction methods must be calculated clearly and accurately.

Compliance with regulations: Meeting building standards, safety standards, environmental protection, and accessibility requirements for the project.

8.2. Construction phase

Foundation: Pay special attention to constructing the foundation as it is the most important part of the structure.

Steel structure: Calculate the size of columns and trusses accurately to avoid excess or deficient materials. Install the bracing first, then continue with other components like columns, trusses, purlins, and roof bracing.

Concrete and roofing: Choose dimensions, thickness, and functionality of precast concrete slabs suitable for usage needs. Install the roofing sheets according to specifications, ensuring aligned connections, forming a right angle with purlins to ensure aesthetics and quality.

8.3. Utility systems

Electrical systems: Install circuits, transformers, and distribution cabinets safely and efficiently to provide stable energy for the workshop.

Water supply and drainage systems: Provide clean water, treat wastewater, and ensure water supply needs for production and daily use.

HVAC systems: Design heating, ventilation, and air conditioning systems suitable to requirements, ensuring comfort and efficient air processing.

Fire protection: Install sprinkler systems, fire alarms, and use fire-resistant materials to ensure maximum safety.

8.4. Safety

Labor safety: Equip personal protective equipment (PPE), apply fall prevention measures and strictly comply with safety protocols.

Emergency preparedness: Conduct fire drills, plan evacuation, and install clear warning signs for hazards.

Adhering to these notes not only helps the workshop project meet high standards but also creates a safe and efficient working environment.

9. BMB Steel - International standard industrial factory construction company

BMB Steel is one of the pioneering enterprises in the design and construction of factory construction in Vietnam. With many years of experience executing numerous large and small projects both domestically and internationally, BMB Steel has become a reliable choice for investors seeking affordable, high-quality, reputable, and professional workshop construction solutions.

BMB Steel has a team of skilled architects, engineers, and workers who always work with a high sense of responsibility to provide customers with absolute peace of mind regarding project quality. In addition, BMB Steel invests in a closed workshop system and advanced production equipment, ensuring that the processing - assembly process meets technical standards, thereby enhancing the durability and aesthetics of each project.

Building factory construction is a complex process requiring thorough preparation and compliance with construction standards. By choosing a reputable construction unit, businesses can ensure progress, quality, and reasonable costs for their projects. Please contact BMB Steel - a prestigious prefabricated steel construction company to receive detailed advice and precise quotes for your workshop construction project.