What is a beam? Functions and classifications of beams

“What is a beam?” is a common question among those new to the construction field or anyone reviewing a project quotation. In construction, beams are essential structural components that play a critical role in distributing loads and maintaining the stability of a building. If you’re wondering about beams, their functions, types, and how beams are designed and placed correctly, let’s explore all the details in this article with BMB Steel.

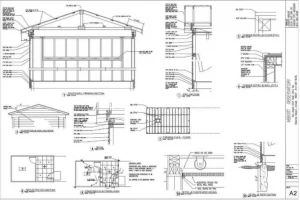

1. What is a beam?

A beam is a structural element in the form of a bar (mainly subjected to bending) that is usually positioned horizontally or slightly inclined to support the floor, wall, roof. In terms of shape, beams typically have a rectangular or I-shaped cross-section, with their length being much greater than their height and width.

Beams have a relatively simple structure and low construction cost, making them widely used in most building projects, such as floor beams, roof beams, crane beams, bridge beams, etc.

In practice, beams are subjected to various types of forces, so their load-bearing capacity depends on multiple factors. Therefore, the design and construction of beams must be carried out by qualified engineers to ensure the overall safety and stability of the structure.

Read more: Common types of steel structures

2. Functions of beams in construction

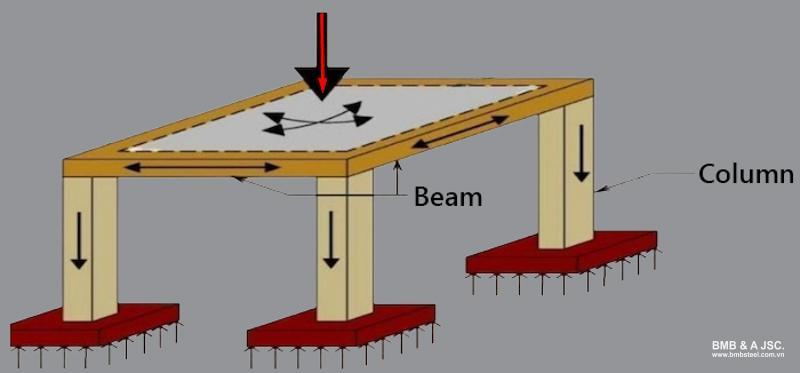

After understanding what is a beam, let’s explore its functions in construction. If the foundation is considered the solid base of a building, then the beam serves as the main load-bearing component that maintains the overall stability of the structure.

The primary function of a beam is to resist bending and transfer loads. All loads from the floor, roof, walls are transferred to the beams, which then distribute these loads to the columns and foundation. This principle ensures that forces are evenly distributed throughout the structure, reducing the risk of deformation or subsidence under heavy loads.

In addition to bearing internal loads, beams also play a crucial role in resisting external impacts such as wind, vibration, collision. Beams help maintain the shape and rigidity of the structure, forming a strong framework that minimizes cracking, warping, or instability over time.

3. Common types of beams in construction

In construction, beams can be classified according to various criteria such as function, orientation, material composition, etc. Each type of beam serves a specific purpose suited to different types of structures. Below are the most common types of beams used today:

3.1. Classification by function

Main beams

The main beam is designed to span between columns, walls, column bases. It is usually placed horizontally or longitudinally and serves as the primary load-bearing component of the structure.

Main beams are typically larger in size than other types of beams and are also known as frame beams. Thanks to their strong structure, they are widely used in many applications such as floor beams, bridge beams, roof beams, etc.

In construction, main beams are often embedded in walls with a typical width of 20-25 cm. Between two columns, the main beam is divided into spans with secondary beams spaced approximately 4-6 m apart. Each span may have 1-3 secondary beams for additional support. If the room length exceeds 6 m, the secondary beams should be placed perpendicular to the main beams.

Secondary beams

A secondary beam rests on the main beam or other bending and torsional members, but not directly on column tops or compression members. Secondary beam systems are usually used to support balconies, bathrooms, or subfloors.

Secondary beams are smaller than main beams and are often placed at right angles to them, distributing loads more evenly and reinforcing the overall structure.

In some cases (except for balcony or stair beams), when all beams are supported directly on columns, the distinction between main and secondary beams is not applied; instead, beam size is determined based on load-bearing requirements.

Distinguishing between main and secondary beams allows for accurate calculation of stiffness, dimensions, and load distribution in the structure.

Read more: Construction of manufacturing industrial factories

3.2. Classification by orientation

Longitudinal beams

A longitudinal beam runs along the length of the building and is less common in residential construction. Its main role is to bear loads in the longitudinal direction.

Transverse beams

A transverse beam is positioned across the width of a building. It is commonly used in structures where the width is significantly greater than the length.

3.3. Classification by material

Steel beams

Steel beams are made from steel and have excellent bending and torsional resistance. With a simple structure, they are widely used in factories, warehouses, prefabricated buildings, and industrial facilities.

Steel beams can be classified by structure, application, and cross-sectional shape as follows:

- By structure

- Simple beam: Consists of a single load-bearing member, suitable for light-load structures.

- Standard steel beam: Composed of intersecting members, capable of withstanding heavy loads.

- Continuous beam: Comprises multiple connected spans for better load distribution and higher strength.

- Cantilever beam: Fixed at one end and free at the other, commonly used for balconies, canopies.

- Overhanging beam: Has an extended end to save material while maintaining strength.

- By application

- Floor beam: Runs across the building width, supporting the floor and transferring loads to columns and foundations.

- Crane beam: A specialized steel beam, often made from an I-beam or built-up steel, which carries crane loads in industrial workshops.

- By cross-sectional shape

- Rolled beam: Usually in I-shape for floors, bridges; or U-shape for inclined structures.

- Built-up beam: H-shaped, fabricated from three steel plates welded together.

- Riveted beam: L-shaped, composed of one web plate and one flange plates.

- Other shapes include C, V, Z beams.

Reinforced concrete beams

Reinforced concrete beams are the most common type today, made of an internal steel reinforcement cage encased in a concrete cover. They provide excellent bending, shear, and torsional strength, and moderate compressive resistance.

Their structure includes:

- Longitudinal reinforcement: Made of steel grades AI, AII, AIII with diameters from 12-40 mm.

- Stirrups: Handle shear forces, made of steel grades AI, CI, about 4 mm in diameter.

- Concrete cover (Ao): The distance from the outer concrete surface to the steel bars, preventing corrosion and ensuring durability. Ao₁ protects stirrups, Ao₂ protects longitudinal bars.

- Clear spacing (To): The distance between two bars, ensuring concrete can flow properly without obstruction.

Concrete cover requirements:

- Ao₁ ≥ 1 cm when h ≤ 25 cm.

- Ao₁ ≥ 1.5 cm when h > 25 cm.

- Ao₂ ≥ 1.5 cm when h ≤ 25 cm.

- Ao₂ ≥ 2 cm when h > 25 cm.

3.4. Other types of beams

Perimeter beams

A perimeter beam runs around the floor or enclosing wall, forming a closed loop. Its functions include:

- Connecting structural elements into a unified system.

- Distributing loads evenly along the wall perimeter.

- Enhancing floor stiffness and stability.

Bridge beams

Bridge beams are the main load-bearing components of bridges, responsible for transferring loads from the bridge deck to piers or abutments. They are typically made from reinforced concrete or steel and may have various shapes such as I-beams, box beams, slab beams, etc.

Girder beams

The term “girder beam” generally refers to large horizontal or inclined members that bear loads within the structure.

4. What is a beam span?

The beam span is the distance between two intersection points of columns and the main beam. This distance is not fixed but is calculated based on the structural design to ensure a reasonable distribution of loads. Typically, the beam span ranges from 4-6 m, and each span usually includes 1-3 secondary beams to provide additional support. Accurately determining the beam span is extremely important, as it directly affects the stability of the structure and the overall aesthetics of the completed construction.

5. What is the beam spacing?

Beam spacing is the distance between adjacent main beams or secondary beams. This distance depends on the design and the position of the columns on the drawing, as the column layout determines how the beams are arranged appropriately. To ensure functionality, load-bearing capacity, and structural safety, the calculation of beam spacing must be carried out carefully and accurately.

6. What are the beam dimensions?

The dimensions of a beam in each construction project depend on the number of floors, though the difference is not significant. Typically, the beam height varies according to the beam span (length), as follows:

- 2-story house: beam height is about 30 cm.

- 3-story house: beam height is about 35 cm.

- 4-5-story house: beam height ranges from 35–40 cm.

Currently, the beam length and beam height are determined based on technical calculation principles as follows:

Beam length:

- According to mathematical and safety principles, l = L (slab span).

- For common floor slabs: l ≤ 18 m.

- For shorter spans, rolled steel beams are often used, while longer spans typically use built-up beams.

Beam height: hmin ≤ h ≤ hmax

Where:

- hmin: the minimum height required to ensure beam stiffness and prevent excessive deflection.

- hmax: the maximum beam height according to the design.

- hopt: the optimal beam height corresponding to the minimum steel consumption.

- During the design process, the closer h is to hopt, the better.

7. Notes when designing and constructing beams

In addition to understanding what a beam is, you should also pay attention to feng shui principles when designing and arranging beams in your house to avoid negative effects on energy flow and the overall spatial harmony. Below are several positions where beams should not be placed:

- Avoid placing beams directly above the bed: According to feng shui, a bed positioned under a beam is considered an unfavorable layout that may negatively affect the homeowner’s health and well-being. Sleeping under a beam can create a feeling of pressure and discomfort, leading to poor sleep quality, fatigue, and anxiety.

- Do not place beams above the kitchen area: Beams positioned over the dining area or kitchen can create a sense of confinement and suppress the family’s positive energy, potentially reducing prosperity and luck. If changing the beam position is not possible, you can install a false ceiling to conceal the beam and minimize its negative feng shui impact.

- Avoid positioning a work desk under a beam: Beams over these areas may cause psychological pressure, distraction, and reduced focus, which can affect productivity and creativity.

- Never place an altar under a beam: This is one of the most serious taboos in home feng shui. A beam above an altar is believed to suppress spiritual energy, reduce wealth, and bring misfortune to the family’s health and prosperity.

Beams are indispensable structural components in any construction project. During the design and construction process, it is essential to accurately calculate the beam’s dimensions, span, and spacing while ensuring proper feng shui arrangement to achieve both structural safety and a harmonious, prosperous living space for the homeowner.

Understanding what is a beam and its function in the structure is only the first step. To ensure your project achieves the highest quality and durability, partner with BMB Steel, a leading provider of steel structures and pre-engineered building solutions.