What is the pre-engineered steel building? The optimal solution for your projects

- 1. What's the Pre-engineered Steel Building?

- 2. Applications of Pre Engineered Steel Buildings

- 3. Advantages and Limitations of Pre-Engineered Steel Buildings

- 4. Structure of Pre-Engineered Steel Buildings

- 5. Type of pre-engineered steel buildings

- 6. Technical Specifications of Pre-Engineered Steel Buildings

- 7. Latest Construction Pricing for Pre Engineered Steel Buildings in 2024

- 8. Most Beautiful, Modern, and Popular Pre-Engineered Steel Building Designs in 2024

- 9. Pre Engineered Steel Building Construction Process at BMB Steel

- 10. Frequently Asked Questions About Pre-Engineered Steel Buildings

- What is the difference between pre-engineered steel buildings and reinforced concrete buildings?

- What factors affect the construction cost of pre-engineered steel buildings?

- Should you build a pre-engineered steel building?

- Where can you find reliable pre-engineered steel building companies?

- BMB Steel as a Leading Choice

Pre-engineered steel buildings are the most popular model in the construction market today because of their superior advantages such as ease of design, high durability, cost savings, etc. To learn more about the features and functions that pre-engineered steel buildings bring, let's find out with BMB Steel in the article below.

1. What's the Pre-engineered Steel Building?

Pre-engineered steel buildings or pre-engineered metal buildings are structures made from factory-manufactured steel components. These steel components include columns, beams, purlins, trusses, walls, and roofing, which are pre-fabricated according to technical drawings and then transported to the construction site for final assembly.

To construct a pre-engineered steel building that meets quality standards and aesthetic requirements, the process is divided into three main phases:

- Design Phase: Concept development and detailed technical drawing preparation

- Manufacturing Phase: Fabrication of steel components in the factory according to technical specifications

- Construction Phase: Transportation and systematic installation of components to complete the structure

The systematic approach ensures quality control at every stage, from initial design to final assembly, resulting in a durable and efficient pre-engineered steel building. Each phase is carefully executed to maintain structural integrity while meeting project specifications.

2. Applications of Pre Engineered Steel Buildings

Pre-engineered steel buildings are currently applied in numerous construction projects including residential buildings, living spaces, warehouses, workshops, kiosks, shopping centers, cinemas, supermarkets, training centers, conference centers, hotels, restaurants, offices, sports centers, parking facilities, and public buildings (schools, hospitals, churches, etc.). Pre-engineered buildings are widely used in daily life thanks to their convenience, low cost, and rapid construction time.

3. Advantages and Limitations of Pre-Engineered Steel Buildings

3.1 What are the advantages of pre-engineered steel buildings?

Today, pre-engineered steel buildings are increasingly widely used due to several outstanding advantages:

- Cost and Labor Savings: The main materials used in pre-engineered buildings are steel, metal sheets, columns, beams, and purlins combined with other cost-effective materials, resulting in significant cost savings. Moreover, construction can proceed easily under various conditions, minimizing the impact of external environmental factors like weather, thus reducing labor costs.

- Rapid Construction Time: As mentioned above, pre-engineered steel buildings are manufactured and designed in the factory. When construction is needed, components are transported to the site and only require assembly, significantly reducing construction time. Furthermore, these structures are highly flexible - they can be easily dismantled when necessary, or upgraded and expanded in the future without excessive time and effort.

- High Versatility and Diverse Applications: Pre-engineered buildings can meet various needs, from residential homes and retail stores to office spaces and industrial facilities like factories or agricultural buildings. The quality and functionality are comparable to traditional reinforced concrete structures.

- Flexible Integration with Other Components: A key strength of pre-engineered steel buildings is their design flexibility. You can easily add features like staircases, mezzanine floors, partition walls, or roof fascias according to usage requirements. This ensures the structure can fulfill all necessary functions of a complete building.

- Adaptability to Various Terrains: Thanks to their lightweight nature and flexible design, pre-engineered buildings can be constructed on various terrains, including rough surfaces or weak soil conditions where traditional reinforced concrete structures would be challenging to build.

3.2 Limitations of Pre-Engineered Steel Buildings

Along with these advantages, pre-engineered buildings have some manageable limitations:

- Lower Fire Resistance: At high temperatures of 500-600°C, steel can deform like plastic, weakening the structure and risking collapse. However, at BMB Steel, this issue is addressed by applying modern fire-resistant coatings to surfaces, ensuring safety for pre-engineered buildings.

- High Corrosion Susceptibility and Lower Moisture Resistance: One challenge of pre-engineered buildings is that steel frames can corrode and rust over time. To ensure long-term protection, steel frames are pre-cast and coated with protective paint, both preventing corrosion and enhancing the building's aesthetic appeal.

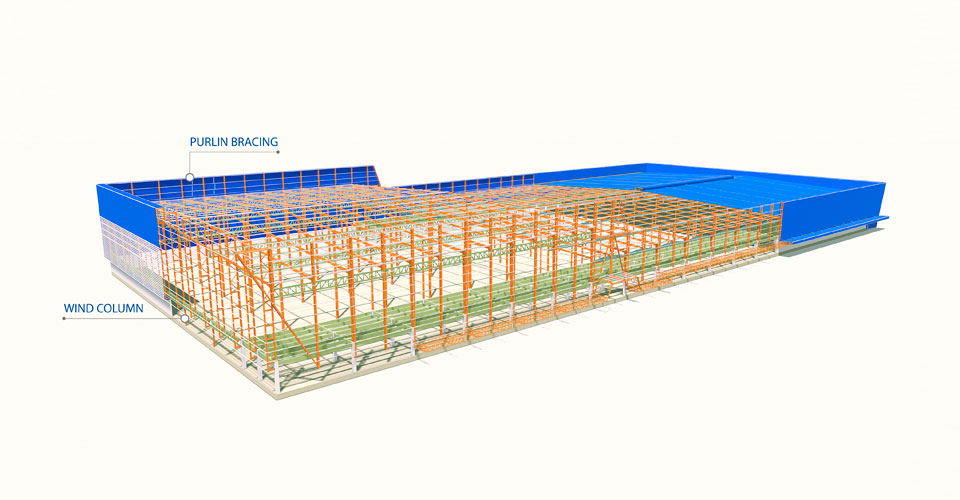

4. Structure of Pre-Engineered Steel Buildings

It's essential to understand the structural composition of pre-engineered steel buildings. The pre-engineered steel building models designed and constructed by BMB Steel consist of three main components:

- "I" Beam Steel Trusses and Column Assemblies

- Galvanized "C" and "Z" Purlins

- Wall and Roof Panels

Furthermore, to enhance the building's aesthetics and optimize functionality, BMB Steel's pre-engineered buildings include additional secondary structures and accessories:

- Secondary Structures: These include:

- Mezzanine floors with load-bearing beam systems

- Crane beams for crane installation

- Roof support systems

- Internal walkways

- Mezzanine rack systems to optimize space utilization

- Accessories and Finishing Details: These include:

- Canopies

- Extended roof sections

- Decorative fascia

- Gutter systems

- Galvanized cable bracing

- Aesthetic facades

- Ridge ventilation systems for improved air circulation and comfort

5. Type of pre-engineered steel buildings

Pre-engineered steel buildings are divided into many different types. However, the main types commonly found in designs in the Vietnamese market include 4 types:

- Pre-engineered civil building: The type designed for people's living. Built for small households to live in. With a quick, easy, low-cost design. So now pre-engineered civil steel buildings are very popular with households. The design of a civil pre-engineered building needs to be fully structured to ensure a solid and comfortable living area.

- Pre-engineered industrial buildings: Built with simple architecture. Create a large space with a simple cover texture. Designing pre-engineered industrial buildings simply mean designing for warehouses, workshops for industrial parks, etc.

- Pre-engineered commercial buildings: Similar to pre-engineered industrial buildings, Pre-engineered commercial buildings have a smaller scale to serve the needs of trading and business locations, etc.

- Pre-engineered military buildings: Designed with a simple structure, serving military needs, such as a training place, a place to store military items, etc.

6. Technical Specifications of Pre-Engineered Steel Buildings

Below are the key technical specifications for pre-engineered steel buildings as designed and constructed by BMB Steel:

|

Parameter |

Description |

|

Length |

Measured from the outer edge of the first wall to the outer edge of the second wall, when viewed from the main entrance. |

|

Width |

Measured from the outer edge of one side wall to the outer edge of the opposite side wall. |

|

Height |

Measured from the column base to the intersection point between the roof and wall panels (roof fascia). |

|

Roof Slope |

Typically designed with a standard slope of i = 15%, ensuring effective rainwater drainage and roof durability. |

|

Column Spacing |

The distance between columns is determined based on the overall building length, ensuring structural balance and load-bearing capacity. |

|

Load Bearing Capacity |

Includes: roof live loads, wind loads, floor loads, etc. |

7. Latest Construction Pricing for Pre Engineered Steel Buildings in 2024

The exact construction cost of pre-engineered steel buildings is determined by various factors including: Project scale and complexity of construction items, geographical location of the structure, and surrounding environmental conditions. Additionally, pricing varies depending on the construction timeline and the quality of materials chosen by the client.

|

No. |

Scale and Area |

Unit Price (VND/M²) |

|

1 |

Pre-engineered steel building construction under 100m² |

1,400,000 - 2,000,000 |

|

2 |

Pre-engineered building construction 500m² - 1,500m² |

1,200,000 - 1,500,000 |

|

3 |

Pre-engineered building construction over 1,500m² |

1,000,000 - 1,200,000 |

|

4 |

Premium pre-engineered steel building construction |

1,500,000 - 1,700,000 |

Note: The above construction prices for pre-engineered steel buildings are provided for reference only. For accurate and detailed pricing information specific to your needs, please contact BMB Steel via hotline (+84 767676170) for prompt and precise assistance. Call now!

8. Most Beautiful, Modern, and Popular Pre-Engineered Steel Building Designs in 2024

Below, we will introduce you to some of the latest and most attractive pre-engineered steel building designs. Let's explore this collection of pre-engineered steel building models!

Modern Single-Story Pre-Engineered Steel Buildings

With advantages in rapid construction time and reasonable costs, single-story pre-engineered steel buildings are becoming an optimal choice for many households. The current market offers diverse unique designs, allowing homeowners to freely choose architectural styles that match their personal preferences.

50m² Pre Engineered Building Models

The 50m² pre-engineered space becomes more luxurious and modern when applying flat roof designs. To create a spacious feeling, homeowners should prioritize using light color schemes for walls and furniture such as white, beige, or pastel yellow. Installing tempered glass doors not only maximizes usable space but also brings natural ventilation to the house.

Single-Slope Pre-Engineered Buildings

Single-slope pre-engineered buildings are characterized by a unidirectional truss frame structure, with a slope extending between two opposing walls. This design is most effective for buildings with widths not exceeding 12 meters. This layout allows the concentration of the entire drainage system along one wall, significantly reducing construction costs.

Double-Slope Pre-Engineered Buildings

Double-slope pre-engineered building models possess both traditional and modern beauty, with symmetrical roof structures creating balance and stability for the construction. This is a suitable choice for those wanting spacious, airy, and aesthetically pleasing spaces.

Pre-Engineered Warehouses and Workshops

Pre-engineered warehouses and workshops are specially designed to meet storage and production needs in various industries. With sturdy steel frame structures, and weatherproof metal or tile roofing, these buildings provide large spaces and low maintenance costs. Quick construction time, easy expansion, and adjustability according to usage needs make them an ideal choice for businesses.

Pre-Engineered Factory Buildings

Pre-engineered factory buildings are the optimal choice for businesses needing to construct production facilities with reasonable costs and short construction times. The sturdy steel structure and flexible design can be customized to suit different functional requirements. This model is commonly used for manufacturing plants, warehouses, or other industrial facilities.

9. Pre Engineered Steel Building Construction Process at BMB Steel

The construction process for pre-engineered steel buildings includes several major phases. The standard process consists of the following stages:

- Requirements Gathering, Conceptualization, and Implementation Planning Based on customer requirements, BMB Steel's expert team will propose optimal solutions regarding design, materials, and construction schedule, along with detailed cost estimates.

- Contract Signing and Project Initiation After agreeing on the proposal, both parties will proceed with contract signing and begin project implementation.

- Technical Drawing Design BMB Steel conducts drawing designs based on customer needs and actual geological conditions to measure and collect data for the most suitable approach.

- Component Fabrication Once the final drawings are complete, architects and fabricators will measure according to standard ratios. They cut and shape materials, create rough drafts, and apply paint according to specifications.

- Pre-Engineered Building Installation After completing the previous steps, installation begins. Materials are constructed and installed on a firmly established foundation bolt system, ensuring the building is securely fixed in place. The installation time and complexity may vary depending on site conditions.

10. Frequently Asked Questions About Pre-Engineered Steel Buildings

What is the difference between pre-engineered steel buildings and reinforced concrete buildings?

Pre-engineered steel buildings and reinforced concrete buildings have distinct differences in structure and construction methods. Regarding load-bearing structures, reinforced concrete buildings are constructed directly on-site through formwork installation, steel reinforcement, and concrete pouring - a process requiring significant time and labor. In contrast, pre-engineered steel buildings have components manufactured in factories and transported to the site for assembly, optimizing time and resources.

What factors affect the construction cost of pre-engineered steel buildings?

The construction cost of pre-engineered steel buildings is influenced by several important factors, with project scale and complexity playing decisive roles. As the scale expands, construction costs increase. With larger projects, not only does the construction area increase, but technical details such as ventilation systems, lighting, and insulation also require more investment. Additionally, supplementary elements like walkways, staircases, canopies, or crane beams contribute significantly to total costs.

Besides scale, the choice of technology and construction materials directly affects costs. Advanced technologies like corrosion-resistant materials, color retention, or heat-reflective materials will have higher prices than conventional materials. Depending on environmental conditions and intended use, selecting specialized materials like leak-proof sheets, screw-fixed sheets, or gutter sheets for high-rainfall areas will create cost variations. Each factor needs careful consideration to ensure optimization between investment costs and long-term usage effectiveness.

Should you build a pre-engineered steel building?

Whether you should build a pre-engineered steel building depends on your needs and conditions. Despite some minor drawbacks, pre-engineered steel buildings remain an ideal choice thanks to outstanding advantages like cost savings, and quick and easy construction. This is a suitable solution for those wanting to own a comfortable, modern home that's quick to build, convenient, affordable, and appropriate for development contexts with limited land and high population density.

Where can you find reliable pre-engineered steel building companies?

There are many companies specializing in pre-engineered steel building construction. However, to choose a reliable provider, you need to consider carefully to ensure maximum benefits. One of the top companies in this field is BMB Steel. This is a professional pre-engineered building design and construction unit currently chosen by many people.

BMB Steel as a Leading Choice

Since 2004, BMB Steel has maintained its reputation as a high-quality, standard-compliant design and construction provider. The materials supplied by the company are all high-quality materials with good heat and moisture resistance, overcoming the disadvantages of conventional designs. The design technique always ensures complete processes and structures, guaranteeing the highest quality results when delivering products to customers.

The above article has helped answer all questions about pre-engineered buildings or pre-engineered steel buildings, an extremely common and popular construction type today. If you need to construct pre-engineered steel building models with the best quality and reasonable costs, contact BMB Steel immediately for the most detailed consultation.