The advantages of pre-engineered steel buildings for remote and challenging sites

In remote and challenging sites, where extreme weather conditions, limited infrastructure, and logistical difficulties pose significant obstacles, the choice of construction method becomes crucial. Among the options available, pre-engineered steel buildings have emerged as a highly suitable and advantageous solution. Their unique characteristics and design make them an ideal choice for addressing the specific challenges encountered in remote locations. This article explores the numerous advantages that pre-engineered steel buildings offer in the context of remote and challenging sites.

1. A brief introduction to the pre-engineered steel building concept

Pre-engineered steel buildings refer to structures that are designed, fabricated, and assembled using standardized components and methods before being transported to the construction site. These buildings are engineered to meet specific requirements and are manufactured off-site, allowing for faster and more efficient construction processes.

The components of pre-engineered steel buildings, such as columns, beams, and panels, are fabricated in a factory and then assembled on-site. This construction method provides numerous advantages, including cost-effectiveness, customization options, durability, and compliance with building codes and regulations. Pre-engineered steel buildings have gained popularity in various industries, including the food industry to meet the unique needs of different applications.

2. The advantages of pre-engineered steel buildings suitable for remote and challenging sites

Below are some advantages of pre-engineered steel buildings that are suitable for remote and challenging sites:

- Strength and durability: Steel is known for its exceptional strength and durability. Pre-engineered steel buildings are designed to withstand extreme weather conditions, including high winds, heavy snow loads, earthquakes, and even hurricanes. This makes them particularly suitable for remote areas where the climate can be harsh and unpredictable.

- Quick and efficient construction: Pre-engineered steel buildings are manufactured off-site in a factory and then transported to the construction site for assembly. This prefabrication process allows for faster construction compared to traditional building methods. As a result, projects in remote locations can be completed more quickly, reducing labor and equipment costs.

- Flexibility: Steel buildings are highly versatile and can be easily modified or expanded to meet changing needs. Their modular design allows for easy assembly and disassembly, making them well-suited for remote sites where transportation logistics can be challenging. Additionally, the flexibility of steel structures enables customization to accommodate specific site requirements and architectural designs.

Pre-engineered steel building in remote area - Cost-effective: Pre-engineered steel buildings often offer cost savings compared to traditional construction methods. The controlled factory environment ensures efficient material utilization and minimizes waste. Moreover, the shorter construction time reduces labor costs and allows for earlier occupancy or utilization of the building, resulting in potential financial benefits.

- Low maintenance: Steel buildings require minimal maintenance over their lifespan. Steel is resistant to pests, such as termites, and it does not rot or warp like wood. Additionally, steel is non-combustible, reducing the risk of fire. These factors make pre-engineered steel buildings well-suited for remote areas where access to maintenance services may be limited.

- Transportation and assembly: Pre-engineered steel buildings are designed to be easily transported to remote sites, even in challenging terrains. The components are typically lightweight, and their assembly does not require specialized heavy machinery. This makes it feasible to construct steel buildings in locations with limited infrastructure and access to heavy equipment.

- Sustainability: Steel is a highly sustainable construction material. It is recyclable and can be used repeatedly without losing its properties. Pre-engineered steel buildings often incorporate recycled content, reducing the demand for new raw materials. Additionally, steel buildings can be designed to incorporate energy-efficient features such as insulation, daylighting, and renewable energy systems, reducing their environmental impact.

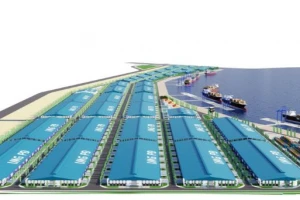

3. Some applications of pre-engineered steel buildings in remote and challenging sites in Vietnam

Hydroelectric power plant: Vietnam's mountainous regions provide ideal conditions for hydroelectric power generation. Constructing power plant facilities in remote mountainous areas requires structures that can withstand seismic activities and challenging terrains. Pre-engineered steel buildings have been deployed to house control rooms, turbine halls, and auxiliary facilities for hydroelectric power plants. These buildings offer design flexibility, adaptability to uneven terrains, and efficient construction processes, facilitating the development of clean energy sources.

Offshore oil rig facilities: Vietnam's offshore oil exploration and production activities demand robust structures capable of withstanding harsh marine environments. Pre-engineered steel buildings have been instrumental in constructing offshore oil rig facilities, including accommodation modules, control rooms, and storage units. These structures offer quick assembly, high structural integrity, and resistance to corrosion, ensuring the safety and efficiency of offshore operations.

Education and healthcare facilities: Pre-engineered steel buildings can be used to construct educational and training facilities in remote areas. These buildings can serve as schools, or classrooms, providing access to education. Besides, pre-engineered steel buildings can be used to construct clinics, healthcare centers, improving access to healthcare services for remote populations.

Above are some advantages of pre-engineered steel buildings for remote and challenging sites. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.