Optimal solutions for designing industrial factory

Building a complete and gorgeous industrial factory is a complicated matter as this process requires a detailed and thorough plan. Thus, a detailed industrial factory drawing is the key factor to make the construction and installation smoother.

1. Industrial factory design

The process of designing an industrial factory has many advantages in the construction. It is considered the most crucial step when starting to carry out every project. In the design drawings, the details and construction plans are clearly demonstrated.

The factory design illustrates plans and details into blueprints for easy visualization. Besides, this is a vital factor in making the construction process to be synchronized with the plan.

The factory design also helps the parties involved in the factory construction to carry out steps according to the requirements of the investment owner and the contractor. Besides, it helps to arrange the factory’s layout efficiently.

On the basis of the design, construction engineers will grasp detailed and accurate information of about the project. It assists engineers and contractors to ensure the industrial factory’s solidity.

Industrial factory design is responsible for calculating and estimating costs clearly and accurately. Investment owners will be more proactive in choosing and purchasing raw materials and equipment.

Additionally, it helps to proactively estimate the budget to avoid a shortage of materials or laborers by virtue of financial problems. An effective industrial factory design is the key factor that makes the construction become faster, accelerates construction progress, and saves costs.

Read more: Prefabricated buildings have become a construction trend

2. Industrial factory design process

It is mandatory for the factory design to follow a certain order, this is a process that requires meticulousness and accuracy. The following factors should be followed in the industrial factory design process:

- First, survey the project and prepare design ideas.

- Second, provide a number of options for installation of techniques, architectural plans and infrastructure structures.

- Third, give priority to options which are related to environmental protection and fire prevention.

- Fourth, calculate the plans to make the foundation compatible with the soil of the factory construction area.

- Fifth, rationally calculate the applicable regulations and standards in the design process of industrial factories.

3. Notes when designing industrial factories

When designing an industrial factory, engineers should consider and pay attention to a number of standards and principles to build an effective factory. Additionally, it helps to utilize the materials and resources.

Pre engineered steel building layout’s division should be based on principles such as: subdivision according to the model of construction land; zoning according to the purpose of each production phase and transportation. Thus, this will ensure and facilitate the production line.

The design of the industrial factory must save land but still increase the construction density. Besides, future expansion plans should be considered.

4. Factory design experience

Along with airy and light space, exits are crucial things for emergencies. In addition, contractors need to focus on designing the foundation carefully because it determines the solidity for the entire factory.

The design process plays a very vital role in a project, especially large projects like factories. Thus, investment owners should carefully consider and choose reputable design companies that have experience in designing industrial factories.

5. Industrial factory designs

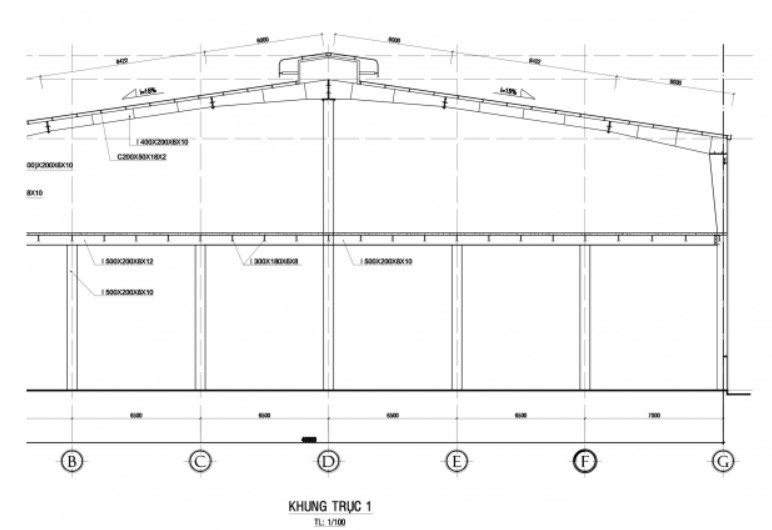

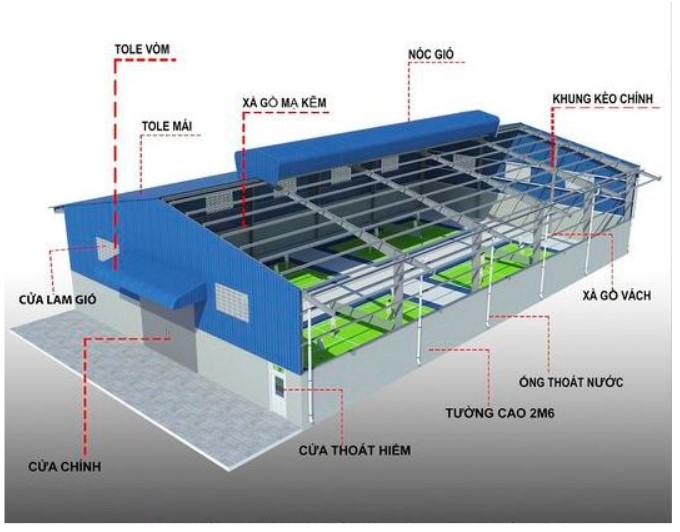

5.1. Modern pre-engineered steel frame industrial factory model

This is an industrial factory model made from a pre-engineered steel frame based on the pre-engineered design. In fact, the projects that apply this design style are usually factories, commercial areas, and places on large scales.

5.2. Factory for food industry model

In a modern style, this model is designed for large projects for many different purposes.

5.3. Packaging production factory model

The design of the packaging factory is relatively uncomplicated. The frame model is built in rows. For the roof, a transparent canopy is used to absorb natural light to save energy.

5.4. Production factory

In Vietnam, factory designs for processing and manufacturing purposes are often built with steel structure fabrication frames with many stages so that the work can be completed quickly but still firmly.

5.5. Factory design model for the purpose of producing wooden furniture

With this design style, architects often design with flexible uses to facilitate the future expansion needs of owners.

The article above is all the detailed information about industrial factory design that BMB Steel has shared to you. Hopefully, the information provided in this article will help readers in the process of designing the factory.

Hi sinh

Hi sinh

Hi sinh