Steel structure introduction

Steel structures have become a vital solution in modern construction. With numerous benefits such as durability, flexibility, and high load-bearing capacity, steel structures are increasingly favored and widely applied in both residential and industrial projects.

In this article, BMB Steel provides detailed information about steel structures, their components, advantages, and real-world applications in construction.

1. What is a steel structure?

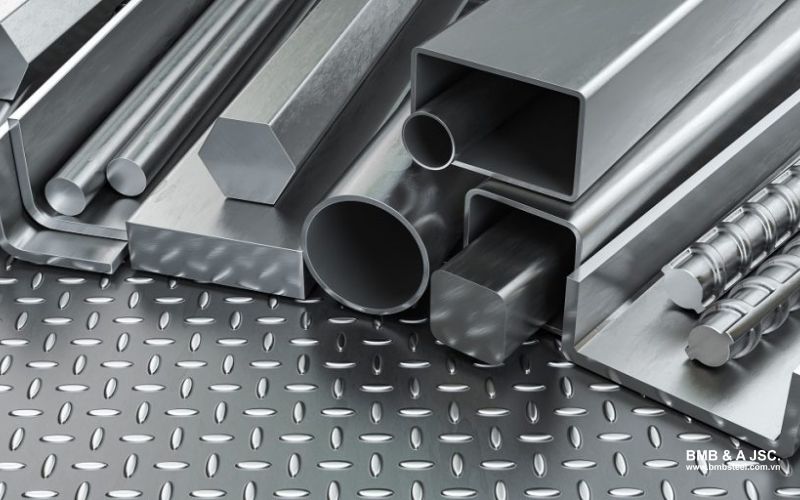

They are typically classified as hot-rolled and built-up products, featuring cross-sectional shapes like angles, channels, I or H, square, rectangular, round. Globally, the demand for steel structures continues to rise steadily.

1.1 Definition of steel structure

A steel structure is a load-bearing system constructed by assembling steel components such as columns, rafters, beams, braces, and connections by bolts or welding. This structure offers high strength, and flexibility in assembly and disassembly, and can be reused if necessary. Compared to other structures like reinforced concrete, steel structures are lighter, faster to construct, and easier to manage in terms of quality control.

1.2 Detailed steel structure description

Steel structures consist of primary elements like columns, rafters, beams, braces, and connections. These components are pre-fabricated in the factory and assembled on-site, forming a sturdy, flexible framework that can be easily modified.

Read more: Prefabricated buildings have become a construction trend

2. Common shapes of steel structures

Steel structures are widely used in construction due to their flexibility and high durability. There are various steel structures, each suitable for specific purposes and project requirements. Below are the most commonly used types in current construction projects

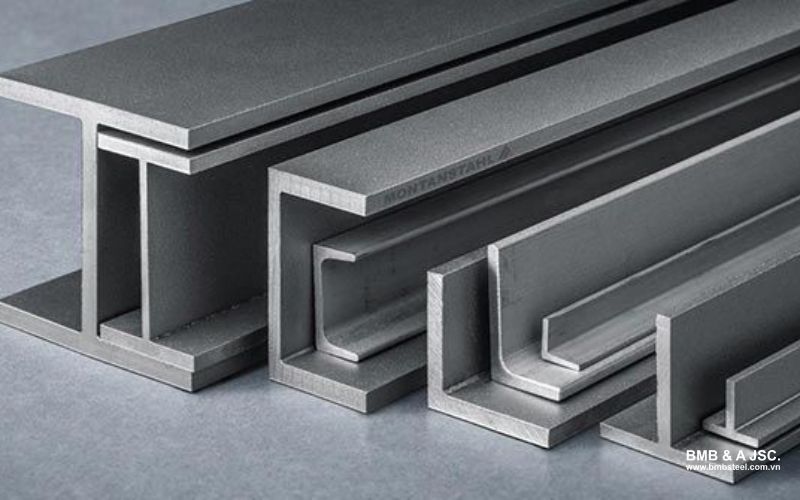

2.1 Z-shaped steel structure

The Z-shaped steel structure is a standard American steel beam with a rolled cross-section and two parallel flanges connected by a web.

2.2 L-shaped steel structure

An L-shaped steel structure consists of two steel legs joined at a 90° angle. These two legs can either be equal or unequal and are typically used in floor systems as they reduce structural depth, saving materials and creating more space.

2.3 H-pile structure

H-pile structures are designed to efficiently transfer loads to pile heads. This type of structure has the best load-bearing capacity and can withstand weights exceeding 1,000 tons, making it ideal for deep foundations.

2.4 C-shaped steel structure

C-shaped steel structures are cost-effective solutions for short- to medium-span structures. They are often used in bridge design and other construction applications where flexibility and load-bearing capacity at a low cost are required.

2.5 HSS hollow steel structure

The HSS hollow steel structure has a cross-section that can be round, square, or rectangular. Engineers commonly use this type of steel structure in welded steel frames due to its high strength and flexibility.

2.6 I-beam steel structure

I-beam steel structures, also known as wide-flange beams, are highly efficient in carrying shear and bending loads within the major plane. They come in various sizes and are often used in projects that require high durability and precision.

2.7 Steel pipe structures

Steel pipe structures are crucial in applications such as water, oil, and gas pipelines. This type of structure is also used in load-bearing frameworks for industrial and civil engineering projects.

2.8 T-Shaped steel structure

T-shaped steel structures are highly load-resistant and are typically used in primary load-bearing systems. However, they lack a lower flange, which can reduce their stability compared to other types.

2.9 Steel plate structure

Steel plate structures are flat, large-sized steel pieces commonly used in large-scale industrial projects, such as factories and warehouses.

2.10 Customized steel structures

For specialized projects or those requiring specific designs, customized steel structures are created to meet unique project requirements. This type of steel structure ensures precision and fulfills the specific needs of each project. Also, creates aesthetic, iconic symbols for building.

Read more: What is the pre-engineered steel building? The optimal solution for your projects

3. Advantages and disadvantages of steel structures

Advantages:

- Durability and high load-bearing capacity: Can withstand heavy loads and environmental forces like wind and earthquakes, ensuring building stability.

- Easy construction and assembly, fast schedule: Prefabricated components reduce construction time, saving both time and costs.

- Lightweight and easy to transport: Lighter than reinforced concrete, reducing foundation load and lowering transportation and labor costs.

- Flexibility in design: Easily adjustable and modifiable, making it ideal for renovations or expansions.

- Cost-effective: Lower production and construction costs; steel can be reused, offering long-term savings.

Disadvantages:

- Limited load-bearing capacity: Thin steel frames might not be suitable for buildings requiring heavy loads or long spans without additional reinforcement.

- Corrosion risk: Steel is prone to corrosion if not adequately protected, which increases maintenance and repair costs.

- Thermal conductivity: Steel transfers heat easily, leading to higher energy costs for heating or cooling and potential discomfort for occupants during extreme temperatures.

4. Properties of steel structures

Steel is an alloy made primarily of iron and carbon, with other elements like manganese, sulfur, copper, phosphorus, chromium, and nickel added to adjust its properties. The performance and behavior of steel structures are largely determined by the chemical composition of the steel. Here are some key properties that influence steel structures:

- Chemical Composition:

- Carbon & Manganese: Increased content enhances tensile and yield strength but reduces ductility and weldability.

- Sulfur & Phosphorus: Excessive amounts can lead to brittleness, reducing weldability and fatigue strength.

- Chromium & Nickel: Improve corrosion resistance and enhance high-temperature durability.

- Copper: Further improves corrosion resistance.

Even small variations in chemical composition can result in different types of steel, used for structural components like pipes, plates, conduits, bolts, rivets, and reinforcing bars.

Steel is produced through processes like heat treatment and alloying to achieve various properties, including:

- Tensile strength: Measured by conducting tensile tests to determine yield strength and ultimate strength, providing a stress-strain curve for the material.

- Hardness: Defined as a material's resistance to indentation and scratching. It is measured using methods like Brinell, Vickers, and Rockwell hardness testing.

- Toughness of notches: This refers to a material's ability to resist crack propagation, especially when subjected to cyclic loading. High-strength steel absorbs more energy before failure, reducing the risk of sudden structural collapse.

- Fatigue strength: Steel can fail under cyclic loading, even if the load is smaller than the maximum load it can withstand in a static test. This makes it essential to consider fatigue strength when designing structures.

- Corrosion resistance: Steel is susceptible to corrosion, especially in humid environments or near saltwater. To combat this, elements like copper, phosphorus, and chromium are added to make steel more resistant to rust and deterioration.

- Rolled steel: Unlike concrete, steel cannot be cast on-site due to its high melting point. Instead, steel components, such as columns, beams, and braces, are manufactured in steel mills and delivered to the construction site for assembly. Rolled steel products are widely used in structural applications for their strength and versatility.

In summary, steel’s properties, including tensile strength, hardness, toughness, and corrosion resistance, make it a highly versatile material in construction. Various elements can be added to steel to optimize its performance based on specific project requirements.

5. Steel structure standards in Vietnam

The standards for steel structures ensure the quality and safety of construction by defining the requirements for steel materials used in building projects. Steel structures in Vietnam must comply with national standards, as well as standards from countries like Australia, the USA, the UK, and Europe.

Once these standards are identified, they become the foundation for constructing, inspecting, and approving steel structures. In Vietnam, the key national standard for steel structures is TCVN 5575: 2012.

Key features of TCVN 5575: 2012:

- Origin:

- Derived from Russian standards with the code SNIP II-23-81.

- Compiled by the Institute of Construction Science and Technology, under the Ministry of Construction.

- Proposed by the Ministry of Construction, appraised by the General Department of Standards and Quality, and announced by the Ministry of Science and Technology.

- Legal framework:

- Recognized as a National standard under Clause 1, Article 69 of the Law on Standards and Technical Regulations.

- It is also stipulated under Point B, Clause 2, Article 7 of Government Decree No. 127/2007/ND-CP, which provides detailed regulations on standards and technical norms.

- Application:

- The standard applies to civil and industrial steel structures but is not used for designing transport or irrigation constructions like bridges, roads, pipelines, or valve doors.

- Design method:

- TCVN 5575: 2012 uses the limit state method, which applies safety factors for load, material, and working conditions.

- It focuses on structural rigidity and disallows significant deformations in the structure's shape.

- Calculation formulas:

- Strength calculation: The formula used is calculated strength = standard strength/material safety coefficient.

- Load calculation: The formula is calculated as load = standard load/load safety factor.

- For multiple effective loads, the standard introduces a simultaneous load reduction coefficient to ensure accuracy in structural load calculations.

- Specific regulations:

- The standard includes specific guidelines for factors such as wind loads, aerodynamic coefficients, and other environmental factors that impact steel structure designs.

TCVN 5575: 2012 plays a critical role in ensuring that steel structures in Vietnam meet safety, reliability, and performance standards in civil and industrial construction projects.

6. Applications of steel structures in construction

Steel structures are widely applied in various types of construction projects, ranging from residential to industrial. Below are some of the most common applications.

6.1 Framework for factories and warehouses

Steel structures are ideal for factories and warehouses due to their excellent load-bearing capacity and fast construction. Steel frames allow for spacious, open areas that are well-suited for production and storage.

6.2 Road bridges and suspension bridges

Steel structures are widely used in the construction of road bridges and suspension bridges due to their ability to carry heavy loads and withstand harsh weather conditions.

6.3 Sports arenas, halls, airport’s roof

Steel structures allow for the construction of large-span buildings, such as sports arenas, exhibition halls, airport’s roof, without requiring excessive internal support columns, creating spacious, flexible interiors.

6.4 High-rise buildings and towers

High-rise buildings and towers often use steel structures to reduce overall weight while ensuring the structure’s strength and durability.

7. FAQ about steel structures

Q1: Are steel structures more expensive than traditional construction?

A: While steel structures may have a higher upfront cost due to materials and skilled labor, they often result in long-term savings due to faster construction times, reduced maintenance, and energy efficiency.

Q2: How long do steel buildings last?

A: Steel buildings can last around 50 years, although some can last up to 100 years with proper maintenance.

Q3: Is steel construction environmentally friendly?

A: Yes, steel is 100% recyclable and can be reused without losing its strength or durability, making it a sustainable building material.

Steel structures provide a modern, sustainable building solution with numerous benefits for construction projects. From flexibility and high load-bearing capacity to cost savings, steel structures are becoming the top choice for owners, contractors, and architects. If you are looking for an efficient, sustainable, and cost-effective building solution, steel structures are the ideal choice for your project.

To learn more about steel structures and receive detailed pricing, visit BMB Steel – the leading provider of steel structure solutions in Vietnam.