Steel Structure Product Warranty and Quality Control Procedure

Quality is always the most significant factor in any pre-engineered steel building project. Therefore, manufacturers are responsible for carrying out the inspection and warranty process for steel structure products. What precisely does this process include? Let’s learn more about BMB Steel by referring to the article below.

1. Standard of steel structure inspection

Currently, there are many sets of quality standards for steel structures in Vietnam and worldwide. Test procedures must be performed based on those common technical standards to ensure consistency.

The current popular sets of steel structure quality inspection standards:

- Vietnam - TCVN 5575:2012: Steel structures – Design standards.

- Vietnam - TCXDVN 170: 2007 on steel structures - Processing, assembly, and acceptance

- America:- AISC-89: American Institute Of Steel Construction, Inc – American Institute of Construction Steel

- England - BS 5950: Part 1: 1990: British Standard: Structure use of Steelwork in Building: British Standard

- Europe - EN 1993-1-1: European standard – Design of steel structures

- Australia - AS 4100-1998: Australian Standard for Steel Structures

- Australia - AS 4600:1996: Australia/New Zealand Standard: Cold rolled steel structure

2. Types of equipment for inspection and maintenance

A competent authority must periodically inspect tools and equipment in accordance with the following regulations:

- Rulers

- Panme

- Weigh

- Nourishes

- Ultrasonic equipment

- Supplies for osmosis and magnetism

- Wet film gauge

- Dry film thickness gauge

3. The process of quality inspection and warranty of steel structure products

3.1 Checking of materials

When entering the warehouse, materials must be thoroughly inspected for standards, origin, and material certificates. The examiner shall take samples, test them, and accept them at a competent agency following regulations.

After the above process, all qualified materials can be put into production.

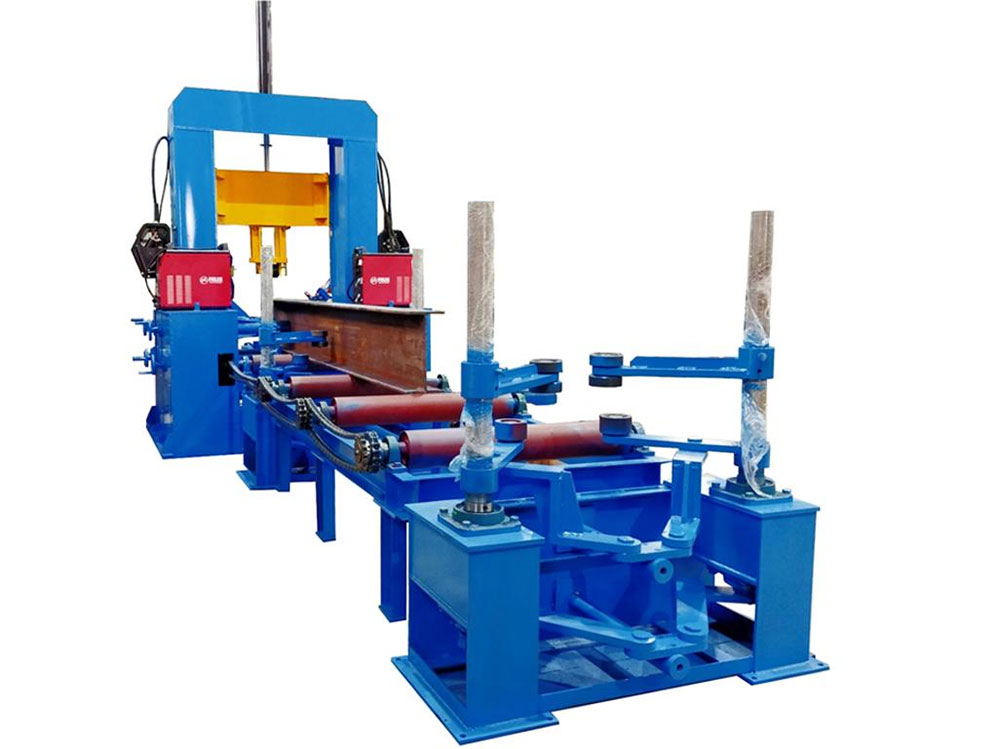

3.2 Inspection during production

The steel structure manufacturing process includes the following stages: cutting, welding, cleaning, and painting finishing products. Quality factors to check include:

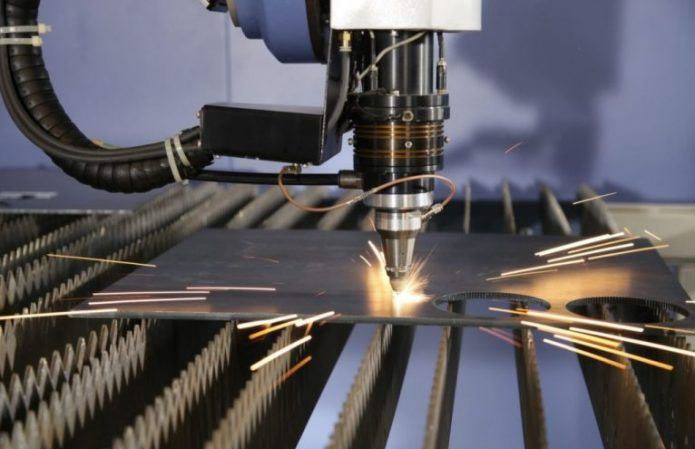

- Cutting: Visually or conduct actual measurements to detect deviations, avoiding mass production of defective products.

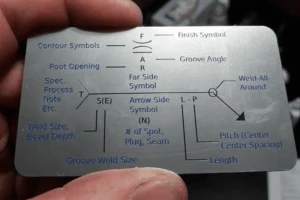

- Welding: The welding must conform to the standards shown in the manufacturing drawings without damage. Ultrasonic and magnetic inspection ensure welding quality so that the weld is clean and there is no deformation after welding. We can use a protractor or caliper to do this step.

- Clean the surface before painting: Carry out comparative sampling or visual assessment.

- Protective coating: Use a wet film gauge and a dry film gauge to check.

In addition, machinery and equipment must also be checked for function, accuracy, and condition of use. If the machine is damaged, affecting the quality of steel, specify it to the production department and ask for remedial action.

The inspection volume should be sufficient to assess the quality of the entire production process. The inspection must be consistent with the regulations and requirements of the design contractor as well as comply with the inspection standards in Section 1.

3.3 Acceptance test

Finished parts will be tested for quality compared with the original material index during construction. They can be checked at regular intervals according to standard or design documents.

If the acceptance test result is unsatisfactory, record the cause, mark it, and request a correction. Then, the re-acceptance testing will be carried out according to the criteria and diagnostics calculated until there are no more defective parts.

3.4 How to overcome common defects

- The welding jig may have deviated. It may not be in the correct coordinates after a period of use or due to improper installation. To avoid mass production of faulty products, it is necessary to regularly clean and reattach according to the reference line, point, and surface.

- Welds are parts that must be carefully examined because defects often appear in this part the most. Welding seams and welds are not aesthetically pleasing because of convexity and porosity; poor quality due to lack of height, mismatched joints, etc. In this case, it is necessary to adjust speed and intensity and recheck the solder and its compatibility with the quality of the solder wire.

In addition, another common defect in welds is ultrasound, penetration, and magnetism. It is necessary to check factors such as brake fluid, penetration clearance, strength, or welding speed.

In cleaning and protective coating, the aesthetic error is mainly. The fix is to respray the ball, clean the surface, check the paint bar, repaint each layer, and ensure the first layer is dry before painting the next layer. Above is the entire process of quality control, warranty of steel structure products, and related information. We hope that we have brought you the necessary useful content. If you have questions about steel structure and related issues, do not hesitate to come to BMB Steel to view our shared articles.