What is carbon steel? Is carbon steel durable?

As the backbone of many construction projects and manufacturing processes, it offers remarkable performance in challenging conditions. In this article, we will delve into carbon steel, its benefits and how BMB Steel can provide you with high-quality carbon steel solutions tailored to your needs.

What is carbon steel?

Among the different classifications of steel, carbon steel stands apart as steel in its most basic form, without the additional alloying elements present in other specialized steels. By definition, carbon steel contains minimal amounts of any elements other than iron and carbon, with chromium levels capped at 0.3% and titanium at 0.05% or lower.

Carbon steel is further categorized by its carbon content into three main types: low, medium, and high carbon steel. Low carbon steel has between 0.02% and 0.25% carbon, medium carbon steel ranges from 0.25% to 0.6%, and high carbon steel contains between 0.6% and 2.14% carbon. Each category has its own unique properties and applications, determined by the amount of carbon present in the alloy.

Is carbon steel durable?

Yes, carbon steel is quite durable, and is widely used in construction, manufacturing, and heavy machinery because it can withstand significant stress and impact.

However, it is important to note that although carbon steel is durable, it can be susceptible to rust and corrosion if not properly maintained or protected. Coating or treatment can enhance its corrosion resistance and extend its life. Overall, with proper care, carbon steel can be a highly durable material, suitable for long-term use.

Advantages and Disadvantages

Below are some advantages and disadvantages of carbon steel when used in construction:

Advantages

- High Hardness and Strength: The carbon content in carbon steel provides excellent hardness and strength, making it suitable for a wide range of applications.

- Versatility: Carbon steel is highly adaptable and can be utilized in various manufacturing processes and products, including machinery and cutting tools.

- Cost-Effective: Generally, carbon steel is more affordable compared to alloy steels, making it a cost-effective choice for many applications.

- Excellent Wear Resistance: The hardness of carbon steel offers good wear resistance, which is particularly beneficial for cutting and drilling applications.

Disadvantages

- Difficult to Weld: The high carbon content can complicate welding, often requiring specialized techniques to achieve successful results.

- Brittleness: While carbon steel is hard, it can be prone to brittleness, leading to potential fractures under sudden stress.

- Limited Corrosion Resistance: Without proper protective measures, carbon steel is more susceptible to rust and corrosion.

- Lower Ductility: Higher carbon content can reduce ductility, making carbon steel less able to withstand deformation under stress.

Comparison of carbon steel and stainless steel

Here’s a comparison table between carbon steel and stainless steel:

|

Feature |

Carbon Steel |

Stainless Steel |

|

Composition |

Primarily iron and carbon |

Iron, carbon, and chromium (at least 10.5%) |

|

Corrosion Resistance |

Prone to rust and corrosion without protective coatings |

Highly resistant to rust and corrosion due to chromium content |

|

Strength |

High strength and hardness |

Good strength, but generally less than high-carbon steel |

|

Ductility |

Varies (low-carbon steel is more ductile) |

Generally more ductile and malleable |

|

Weldability |

Good weldability (depends on carbon content) |

Generally good weldability, though care is needed with certain grades |

|

Cost |

Typically less expensive |

Usually more expensive due to alloying elements |

|

Applications |

Construction, automotive, tools, and machinery |

Kitchenware, medical instruments, automotive, and construction |

|

Maintenance |

Requires regular maintenance to prevent rust |

Low maintenance; resistant to staining and corrosion |

|

Thermal Conductivity |

Better thermal conductivity |

Lower thermal conductivity than carbon steel |

|

Appearance |

Typically matte or dull finish |

Can have a polished, shiny appearance |

Practical applications of carbon steel in construction

Possessing many outstanding properties, carbon steel is widely used in various industries, including:

- Construction: Carbon steel has excellent corrosion resistance and high strength, making it suitable for infrastructure projects such as roads, bridges, buildings, and tunnels.

- Automotive Industry: Carbon steel is an ideal material for vehicle components like frames, doors, hoods, and exhaust systems due to its high hardness, lightweight, and durable structure, which helps reduce weight and optimize space efficiency.

- Aerospace Industry: With its lightweight and superior mechanical strength, carbon steel is used in manufacturing aircraft parts, spacecraft bodies, and rockets.

- Oil and Gas Industry: Carbon steel is utilized in the production of oil equipment and pipelines due to its excellent load-bearing capacity. This ensures the safety and performance of pipeline systems in the harsh conditions of the oil and gas sector.

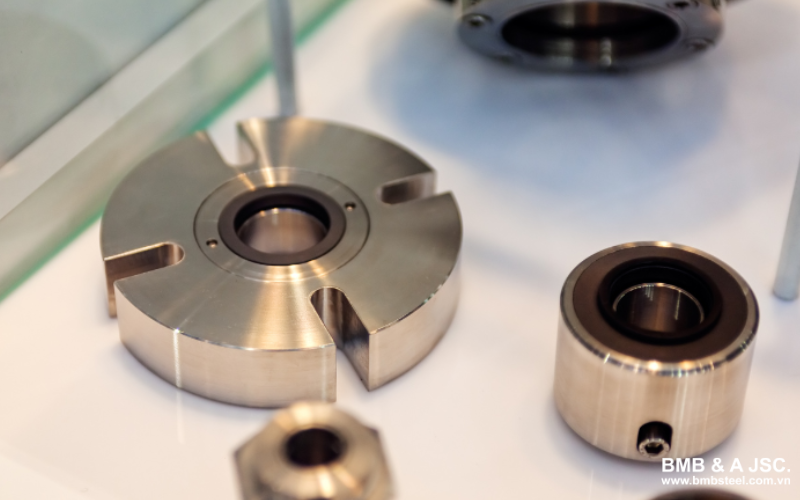

- Manufacturing and Machinery Fabrication: Carbon steel’s ductility and versatility make it suitable for machining and fabricating machine components like shafts, bearings, and gears.

Tips for Storing Carbon Steel

To maintain the quality and durability of carbon steel, consider the following:

- Avoid Moisture: Carbon steel is prone to oxidation in humid conditions. Store it in a dry, well-ventilated area. Use a dehumidifier if necessary to keep the storage space dry and prevent corrosion from moisture.

- Avoid Corrosive Chemicals: Carbon steel should not come into contact with corrosive substances like acids, alkalis, or salts. If chemicals get on the steel, clean them immediately with a soft cloth and rinse with clean water.

- Use Protective Oil: Applying a protective oil layer on the steel surface helps prevent oxidation. Ensure the surface is clean before applying the oil to create a barrier against air and minimize corrosion.

- Protective Coating or Galvanizing: For carbon steel used outdoors or in corrosive environments, consider applying a protective paint or galvanizing. This will reduce the risk of corrosion from weather and chemicals.

- Choose a Reputable Supplier: If you are looking for a reliable source of authentic carbon steel, BMB Steel is an excellent choice. Their carbon steel products meet quality standards such as ISO, ASTM, or JIS, ensuring durability and safety for your projects.

Carbon steel is a high-strength material widely used in various industries and construction due to its excellent load-bearing properties and wear resistance. However, to ensure the longevity of carbon steel, it is important to consider the information provided by BMB Steel above for proper storage measures and regular inspections during use.