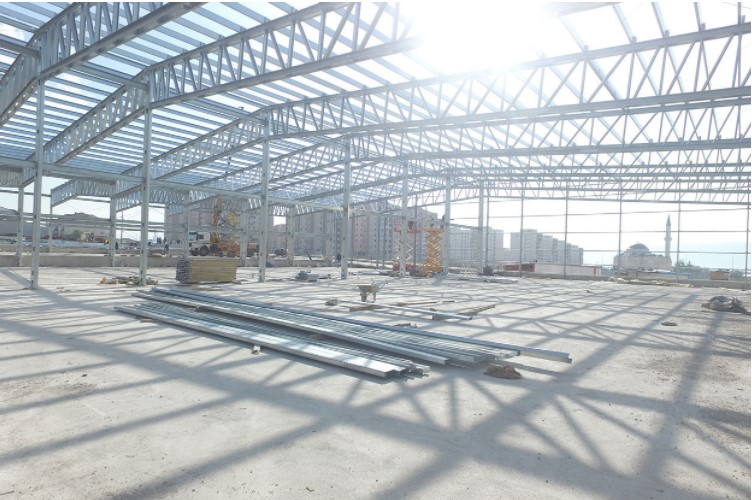

Integral cautions in steel structure construction and erection process

- 1. Cautions before constructing of steel structure

- 2. Cautions while erecting steel structures

- 2.1 Designing steel structure

- 2.2 Supervision of the installation of steel structures

- 2.3 Cautions when moving up and down the construction site of steel structures

- 2.4 Checking the scaffold lock, column system, truss beam

- 2.5 Checking structural bolt tightening force

- 2.6 Check the main azimuth structure of the steel frame factory

- 3. Notes after processing and erecting steel structures

- 4. Important note to help construction workers be safe

When constructing and erecting steel structures, builders and investors need to understand how to operate and build smoothly and conveniently. What should be noticed in steel structures’ construction and erection process to ensure the buildings’ safety and quality. To learn more, let’s explore BMB Steel in the article below.

1. Cautions before constructing of steel structure

1.1 Prepare labor protection pieces of equipment

Ensuring safety at work is a crucial factor in anticipating accidents at work. Protective gears depend on the working activities; in general, protective kits include:

- Reflective clothing

- Helmets, safety harness

- Cloth paper or tarps, soft gloves

- Safety goggles, equipment bags

- Scaffold

- Safety nets

- Lifeline

1.2 Pay attention to the weather

It is indispensable to watch the weather forecast before constructing steel structures for factory buildings to prevent accidents. For instance, solid rainy weather will make it difficult for workers to work in a high, slippery position. Another example is when the weather is windy, it is dangerous to use machinery such as cranes to hoist materials.

1.3 Inspection of equipment, materials, tools, means of transport

Equipment, materials or tools, and vehicles need to be checked for origin certificates before being put into the erection. Especially structural bolts and anchor bolts, it is used to connect essential parts of steel frame buildings.

1.4 Consider building space

By virtue of the fact that vehicles and scaffolding are large and bulky, construction space needs to be carefully checked. In order to have the best conditions for movement, a spacious area is a must-have. Besides, you should prioritize constructing the concrete part of the foundation, walkways, and solid foundations in advance.

It is necessary to have enough space for vehicles to travel between positions on the steel frame, such as stairs and walkways with guardrails. The priority option is to design temporary walkways with wooden trusses or long-span steel bridges. If construction is completed at the height of over 6m (equivalent to two floors), it is mandatory to have a temporary floor made of tightly coupled planks. Steel scaffolding and forklift are devices that increase safety, especially when enough walkways, floor reinforcement boards, temporary floors, and clear construction sites.

2. Cautions while erecting steel structures

The process of steel structure construction has quite a lot of things to do. Here are primary things that are necessary for processing steel structures:

- Manufacture steel truss frame: manufactured steel truss frame needs to meet the standard data as the drawing.

- Erect steel truss frame, continuous ridge vent, door console: Need to be connected firmly; pay attention to the gravity load. When installing, it is necessary to ensure labor safety.

- Install sheet metal roof: The corrugated iron roof layer needs to be connected to the joints.

- Install corrugated iron wall

- Install gutters and drainage pipes: Choose an appropriate location for gutters and drainage pipes to not affect the general structure of the steel truss.

- Install flashings

2.1 Designing steel structure

The design of the steel structure must be coordinated between the designer as well as the installation contractor. This will optimize the construction plan, make the project of the highest quality. Combining the practical site situation and design theories is integral to create a flexible structural steel design.

2.2 Supervision of the installation of steel structures

Different units and construction teams can perform each stage. It is recommended that a specialized individual supervise steel structures’ entire installation and design process to ensure requirements and quality.

2.3 Cautions when moving up and down the construction site of steel structures

Dangerous actions such as climbing on bare steel bars, walking on beams happened frequently. Therefore, it is necessary to calculate, provide adequate means of moving materials and fully prepare labor protection plans. Scaffolding must be solid, and a path for the construction workers is required. There must be a safety net placed in the best safe position on the 2nd floor of the building.

In addition, the work is planned, and the construction is designed to start from the ground. Gradually move to higher places according to the building components, afterward move to another location by the lifting machine.

In general, ladders should be installed before the steel structure is installed to move up and down. The ladder should be fastened to the steel frame to avoid danger to people standing on it when the ladder is accidentally moved. For example, you are allowed to move the ladder with a crane only after fastened.

2.4 Checking the scaffold lock, column system, truss beam

The system of columns, beams, or trusses is a significant foundation, so it is necessary to carefully check for absolute certainty after the construction and erection of the scaffold lock. If it has been moved, you have to suggest a solution to get over this problem.

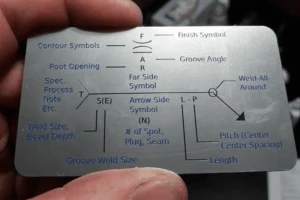

2.5 Checking structural bolt tightening force

It is necessary to check and tighten bolts of 4.6/s and 8.8/s criteria. Extra spacers or shims should be used to ensure that force transfer surfaces touch each other when the connection is tightened.

Bolt tightening, and final tightening of bolts should be carried out from the most challenging part of the joint to the edge of the connections.

Before creating a tightening force, you have to align the position and direction of the bolt to see whether it has met the requirements or not.

Do not tighten the bolts that have been done before. In cases it is necessary to tighten the tightened bolts, the following principles must be followed:

- Only tighten once where the bolt is still in the correct hole with the same arm length.

- Do not reuse tightened bolts in another position.

- Galvanized bolts must not be tightened.

- Further tightening or re-tightening of loosened bolts when tightening the next-to bolts is not considered re-tightening.

The vital thing to pay attention to here is that the final tightening of the bolts is carried out only after the azimuth and elevation have been adjusted as required.

2.6 Check the main azimuth structure of the steel frame factory

Checking the correct azimuth is compulsory; it will make the installation easier for builders. Do not connect the structures with a permanent bond.

3. Notes after processing and erecting steel structures

After the steel structure manufacturing processing is completed, it is time to check and take over. Acceptance of construction of steel structures must also follow the process and should be noted:

- Acceptance of construction work: Check the scaffolding system and construction process to ensure labor safety.

- Acceptance of construction phase completion: inspecting the building at the site and checking the work’s acceptance minutes and related components.

- Acceptance and completion: All completed areas must be checked and recorded on the handover minutes with detailed information before being used.

4. Important note to help construction workers be safe

- Prepare safety nets and maintain safety nets throughout the working process, especially for works from the 2nd floor and higher.

- Prepare safety gear.

- Prepare professional skills in advance to avoid injury, especially the spine, in moving construction materials.

- Attach handles at both ends of the steel frame when erecting with a crane. Keep a safe distance of at least 5m.

BMB Steel has shared with you the essential notes of the steel structure construction process. Hopefully, this helpful information may help your project complete quickly, smoothly, and conveniently.