What is shaped steel? Types, advantages, disadvantages

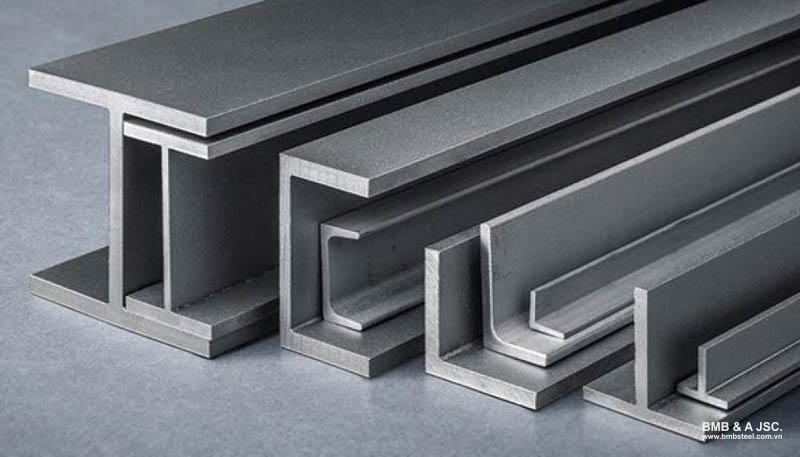

Shaped steel is an indispensable material in today's construction and industrial sectors, thanks to its high durability, flexibility, exceptional load-bearing capacity. So, what is shaped steel? How is it produced, which types are most popular? Let’s explore with BMB Steel in the article below.

1. What is shaped steel?

Shaped steel is designed in specific letter shapes such as I, V, U, H, L, C, etc. These shapes are manufactured to meet various technical requirements, usage purposes in construction and industry.

2. Shaped steel production process

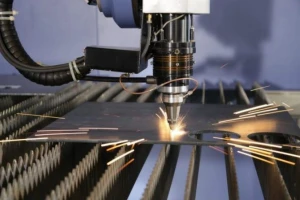

The shaped steel production process consists of 3 main steps as follows:

2.1. Removing impurities and melting the ore

First, raw iron is purified by removing impurities, excess materials, scrap. All these materials are placed in a furnace at an extremely high temperature to be melted. This process, known as steelmaking, produces a purer iron alloy, forming the foundation for the next step.

Read more: Prefabricated buildings have become a construction trend

2.2. Melting and adding metals to form steel billets

Modern melting techniques combined with the addition of other metals enhance the steel’s properties, resulting in steel billets. Depending on the intended use, metallic elements such as carbon, manganese, silicon,... are added to increase strength, flexibility, heat resistance.

2.3. Creating steel billets and final products

The steel billets produced in the previous step vary depending on the type of metals added during the melting process. There are 3 main types of steel billets:

- Slab billets: are rectangular billets, commonly used for manufacturing hot-rolled steel coils, hot-rolled steel sheets, cold-rolled steel coils, shaped steel. Slab billets are more widely used in steel production plants.

- Billets: With a square cross-section (100×100 mm, 125×125 mm, 150×150 mm), lengths typically ranging from 6–12 meters. Billets are often used for manufacturing construction steel such as rebar and steel coils.

- Bloom: A versatile billet that can replace both slab billets and billets, widely used for producing various steel products.

Once the billets are cast, they exist in 2 states:

- Hot state: The billets are maintained at a high temperature, immediately proceed to the rolling stage to shape the final product.

- Cold state: The billets are cooled, transferred to other factories for further processing. Afterward, the billets are reheated before being rolled into the final product.

3. Advantages of shaped steel

- Shaped steel has excellent impact resistance and high pressure tolerance, ensuring long-lasting durability for construction projects.

- It is manufactured in various shapes and sizes to meet different technical and design requirements.

- Thanks to its lightweight nature, shaped steel significantly reduces the overall weight of steel structures.

- All shaped steel components are meticulously fabricated at the factory and delivered to the construction site, which not only shortens construction time but also saves on labor costs.

- With a flexible design, shaped steel allows for quick, easy assembly of components, ensuring smooth construction progress.

- The galvanized coating on shaped steel protects it from corrosion caused by weather elements such as rain, wind, etc.

4. Popular types of shaped steel

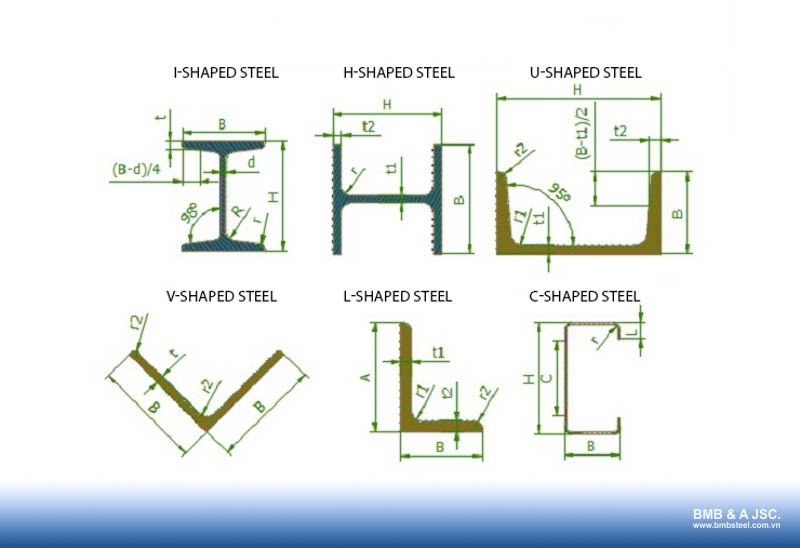

4.1. I-shaped steel

I-shaped steel is widely used in construction projects, workshops, mechanical engineering, bridges, etc. However, it is often confused with H-shaped steel due to structural similarities. The most noticeable difference is that the flange width of an I-shaped is shorter than its web height, while H-shaped steel has equal proportions of web height and flange width.

Standard specifications of I-shaped steel:

- Height: 100mm – 600mm

- Flange width: 50mm – 200mm

- Length: 6000mm – 12000mm

4.2. H-shaped steel

H-shaped steel, designed in the shape of the letter H, features excellent structural balance, outstanding load-bearing capacity. This type is widely used in construction for beams, columns, roof structures, crane towers, etc. H-shaped steel is available in various sizes and proportions to meet diverse technical requirements.

Standard specifications of H-shaped steel:

- Height: 100mm – 900mm

- Flange width: 50mm – 400mm

- Length: 6000mm – 12000mm

4.3. U-shaped steel

U-shaped steel, with a cross-section resembling the letter U, is known for its precise corners and edges. This characteristic makes it suitable for manufacturing agricultural tools, transport vehicles, industrial equipment repairs. U-shaped steel offers excellent resistance to torsional forces and horizontal loads.

Standard specifications of U-shaped steel:

- Width: 40mm – 500mm

- Flange height: 25mm – 100mm

- Length: 6000mm – 12000mm

4.4. C-shaped steel

C-shaped steel, also referred to as Z-shaped steel, is lightweight, durable, easy to fabricate. Its cross-section is similar to U-shaped steel but features smaller flanges that curve inward. Holes are often pre-punched to simplify assembly into frames or purlins for factory structures.

There are 2 main types: black C-shaped steel and galvanized C-shaped steel, each suited for specific applications.

Standard specifications of C-shaped steel:

- Width: 80mm – 300mm

- Flange height: 40mm – 80mm

- Length: 6000mm – 12000mm

4.5. V-shaped steel

V-angle steel is shaped like the letter V, providing high strength and durability. It is commonly used in construction and shipbuilding. V-shaped steel resists environmental factors such as humidity, high temperatures, chemicals.

Galvanized V-shaped steel is especially popular due to its superior load-bearing capacity and shiny appearance.

Standard specifications of V-shaped steel:

- Flange length: 25mm – 250mm

- Length: 6000mm – 12000mm

4.6. L-shaped steel

L-shaped steel, also known as unequal angle steel, differs from V-shaped steel (which has equal flanges). With its robust structure, L-shaped steel is ideal for projects like chemical plants, pipelines, oil and gas facilities.

L-shaped steel is categorized into: galvanized angles, hot-dip galvanized angles, black angles steel.

Standard specifications of L-shaped steel:

- Dimensions: Vary based on project requirements

- Length: 6000mm – 12000mm

5. Advantages and disadvantages of some types of shaped steel

|

Advantages |

Disadvantages |

|

|

I/H shaped steel |

|

|

|

U/C shaped steel |

|

|

|

V shaped steel |

|

|

|

L shaped steel |

|

6. Applications of shaped steel

Shaped steel has become an indispensable material in various fields with its outstanding advantages. Below are some common applications of shaped steel in life:

In construction

- Used for columns, beams, trusses in factories, warehouses.

- Used to create the structure for bridges, guardrails.

- Applied in high-rise buildings as load-bearing frameworks, partitions.

In industry and agriculture

- Used for creating frames, shells for industrial machinery.

- Used as beams, frames for port structures, greenhouse frames in modern vegetable cultivation models.

- Applied in shipbuilding.

In household and daily life

- Used for door, gate frames.

- Used to create railings, shelves, other fixtures in living spaces.

Shaped steel has proven its importance in industries, construction, daily life, with its diverse types, sizes and superior advantages. Choosing the right type of shaped steel helps ensure the durability, cost-effectiveness of your project.

We hope this article has provided you with useful information to better understand what is shaped steel. For the most suitable choice of shaped steel for your project, feel free to contact BMB Steel to receive expert advice and support from our top engineers in steel structure construction.