Construction standards and the acceptance of steel structure

Pre-engineered steel buildings are increasingly popular by virtue of their advantages, such as optimizing construction costs, short construction time, etc. Parallelly, owners are also concerned about some problems. In this article, BMB Steel will provide you with helpful information about construction standards and the acceptance of pre-engineered steel buildings.

1. What is the steel structure?

When building a project, the construction standard and acceptance of steel structures are two integral factors. Learn more about the characteristics of steel structures with BMB Steel below.

Steel structure, known as force-bearing steel structure, is used in construction, especially in large-scale projects. For instance, the pre-engineered buildings are designed and constructed entirely from steel.

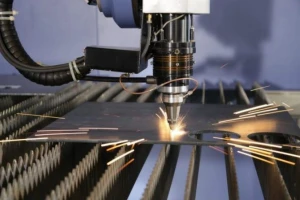

2. The steel structure manufacturing process

At BMB Steel's factory, the steel structure fabrication process is conducted according to the following procedure:

- Cutting steel billet

- Pledge components

- Automatic welding

- Straighten the structure

- Welding the gusset plates, reinforcing ribs, drilling holes

- Shot blasting and cleaning the surface of the structure

- Painting

3. Requirements of steel and welding consumables

It is integral to meet steel and welding materials requirements for pre-engineered buildings to ensure the construction’s quality.

Therefore, the design and construction contractors of pre-engineered steel buildings should ensure strict compliance with the following standards:

- Steel should be checked explicitly in advance according to the design requirements.

- Classify, mark, and sorted steel into sections to avoid confusion with other types. Different types of steel must be marked with different colors.

- Steel must be straightened, cleaned of oil, grease, and impurities before using. The radius of curvature and the allowable being deflection must comply with the standards.

- Steel must be securely protected in a sheltered house. If it is put outdoors, it should be covered with a protective coating. When stacking, it must be lined and tilted so that it can be quickly drained.

- When transporting steel, it is vital to have a set of racks so that the steel is not deformed.

- Before using, the quality of soldering iron, welding wire, and solder must be checked in accordance with the provisions of the current standard or technical conditions.

- Welding rods, wires, solder must be appropriately dried.

- The amount of soldering iron and solder that has been dried from the oven can only be used in one production shift (if welding on low-carbon steel) or enough for two hours (if welding on low alloy steel).

- The selection of appropriate welding rods, wires, and fluxes should take into account the strength of the parts to be welded and the weldability of those parts. Soldering irons that are peeled, dirty, or damaged should not be used.

- Paint protection materials for steel structures must comply with the standards of TCVN 8789:2011.

4. Steps to supervise the construction materials

- Checking the contractor's steel structure construction process

- Checking the steel structure manufacturing contractors

- Checking the contractor's quality management system

- Supervising the steel structure manufacturing

- Supervising the structural inspection experiments

- Inspecting and acceptance of manufactured steel structure products

- Supervising the transportation and erection of steel structure wire.

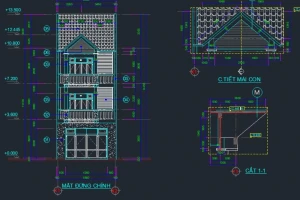

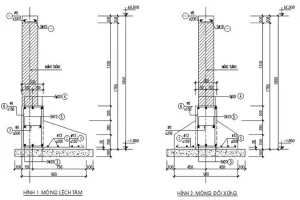

5. Construction standards for pre-engineered steel buildings

Pre-engineered steel buildings are built by erecting and assembling components, so the entire steel structure must be closely connected.

To ensure the quality of the construction, it is imperative to comply with the construction and acceptance standards of steel structures based on TCXDVN: 170:2007:

- Steel structures need to be manufactured and erected according to structural and detailed drawings. Along with the general standards, there are specific regulations for this structure.

- When erecting and assembling, mechanical methods and effective block methods will be used to match construction methods and technology diagrams.

- It is essential to check the implementation of the technological diagram and construction methods during processing, assembly, and acceptance. The test results must be recorded in the construction log.

- Steel structures need to meet design requirements of bearing capacity, including strength, fatigue, stability, and deformation.

- Structures under the direct effect of fire must keep their bearing capacity and integrity for a certain period.

- Steel structures need to be protected against corrosion; they are shown in the design drawings according to the building’s standards for corrosion protection.

- Corrosion protection layer should be carried out in factory conditions and steel structure manufacturing factories.

6. Advantages and disadvantages

6.1 Advantages

- Strong bearing capacity, the steel structure is difficult to deform.

- More lightweight than concrete.

- Simple structure, easy to transport, construct, and repair

- Applicable for all large projects.

- Waterproofing.

- Short construction time.

- Cost-saving.

6.2 Disadvantages

Besides the above advantages, steel structure also has some disadvantages such as:

- Easily oxidized by environmental influences such as temperature, light, weather conditions.

- Poor fire resistance.

- The cost is higher than other common materials such as iron, wood, etc.

In the article above, BMB Steel has shared with you some standards for construction and acceptance of steel structures. To build a high-quality construction, it is vital to understand the requirements of steel structure works, the construction standards, and the acceptance of steel structures. In addition, you can refer to the construction methods of steel structures to choose a plan that suits your budget. If you need any information about steel structure, please contact us immediately.