What is a roof truss? Common types and installation guide

Roof trusses form the backbone of a building's roof structure, providing stability, support, and design versatility. In this article, let’s explore with BMB Steel what is a roof truss, its components, common types, and step-by-step installation guidance to help ensure a reliable, durable roof.

1. What is a roof truss?

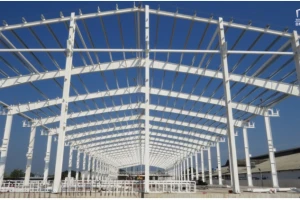

A roof truss is a pre-fabricated, engineered framework that forms the roof's structure, typically in a triangular shape made of timber or steel. Its primary function is to evenly distribute the roof's weight across supporting walls, providing strength and stability. Roof trusses work with purlins, beams and walls to create a durable roof structure that enhances support and aesthetics, commonly seen in airports, stadiums, factories, warehouses, etc.

2. Roof truss components

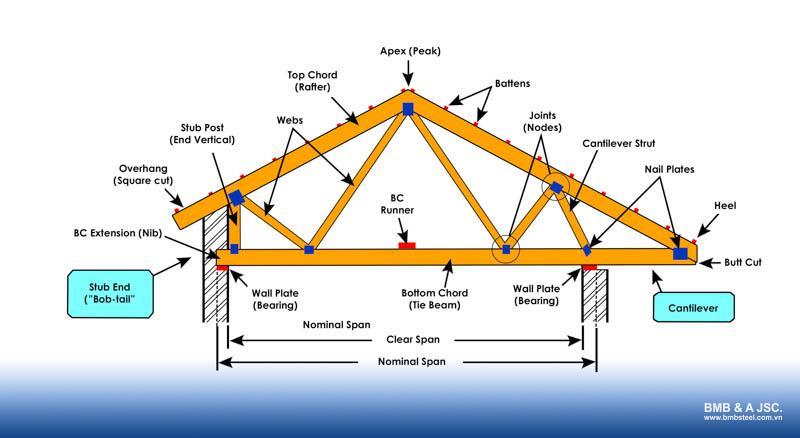

Understanding the components of roof trusses is essential for grasping their structural function. Here’s a breakdown of key elements:

- Apex: The highest point where the sloping top chords meet.

- Bearing: The structural support for trusses, typically accompanied by a timber wall plate.

- Bottom chords: The lowest longitudinal members of the truss, supporting tension.

- Cantilever: The portion of a structural member extending beyond its support.

- Cantilever strut: A web connecting the bottom chord over the bearing point to the top chord of a cantilevered truss.

- Chord: The main outline members of a truss, experiencing axial force and bending.

- Clear span: The horizontal distance between the inner edges of the supports.

- Heel: The truss point where top and bottom chords intersect.

- Joint: A point where at least one web intersects a chord.

- Nail plate: A galvanized steel plate, punched to form a nail pattern, used to connect members.

- Node: The point of convergence of two or more members forming truss panels.

- Nominal span: The horizontal distance between the outer edges of supports, often the tie beam length.

- Overhang: The extension of the truss’s top chord beyond the bearing support.

- Panel: A segment of a truss with two adjacent joints or nodes.

- Plumb cut: A vertical cut at the top chord’s end to allow vertical installation of a gutter or fascia.

- Splice point: The connection point between the top and bottom chords.

- Square cut: A perpendicular cut to the edge of a chord.

- Stub end: A truss type created by truncating a standard triangular truss.

- Top chord or rafter: The upper member of the truss that supports the roof covering.

- Web: Connect the top and bottom chords, forming a triangular shape within the truss.

3. Benefits of roof trusses

Roof trusses are crucial components in any construction project, offering several structural and practical advantages. Here are some key benefits:

- Sturdy: Roof trusses distribute weight evenly across the structure, creating a strong and stable framework that enhances overall building integrity.

- Versatile: Available in various types and styles, trusses can be customized to fit projects of any scale, from small sheds to large homes, adapting to unique architectural designs.

- Lightweight: Constructed with lightweight materials, trusses are easy to transport and install, making assembly on-site more manageable.

- Cost-effective: Built off-site, roof trusses reduce labor costs, construction time, leading to significant cost savings on overall project expenses.

- Supports open-concept designs: Certain trusses can span large distances, allowing for open-concept layouts without the need for interior load-bearing walls, maximizing floor plan flexibility.

- Indoor climate control: A well-supported roof with trusses helps block UV rays, withstands extreme weather, creating a more comfortable, cool, and energy-efficient indoor environment.

- Protection: Trusses reinforce the roof, the building’s first defense against environmental elements like sun and rain, ensuring better protection and durability.

- Precision fabrication: Manufactured in controlled environments with digital measurements and cuts, roof trusses are made with high accuracy, minimizing errors, ensuring consistent quality.

4. Common types of roof trusses

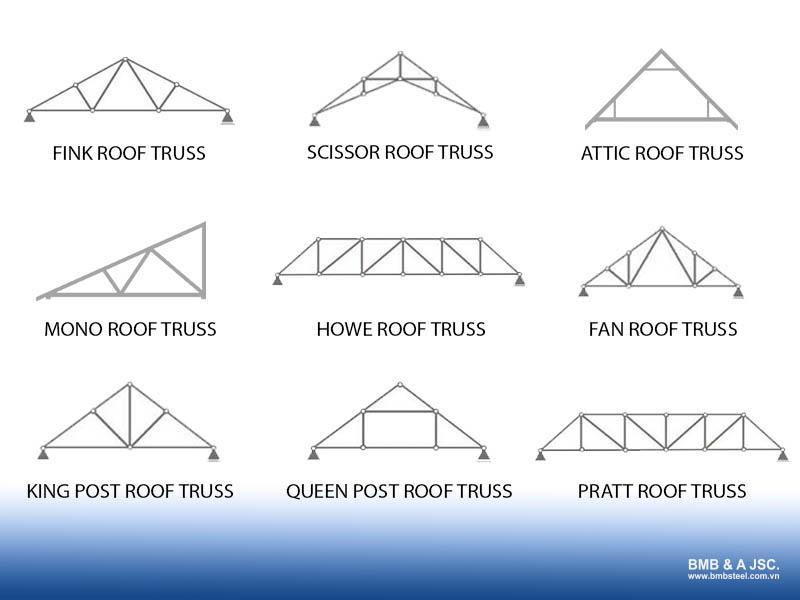

In addition to understanding what is a roof truss, it’s essential to choose the right type of roof truss to suit your project and budget. There are many different designs of roof trusses available, but some of the most common include:

4.1. Fink roof truss

The fink roof truss is one of the most popular choices in residential construction. It’s ideal for longer spans and is often used to achieve high-pitch roof designs.

4.2. Scissor roof truss

Often used in churches, cathedrals, etc. This truss has intersecting bottom chords that resemble an open pair of scissors. It supports vaulted ceilings and adds architectural interest while offering stability for expansive roof structures.

4.3. Attic roof truss

Also called room-in-attic trusses, these provide extra storage or living space within the roof. The bottom chord acts as a floor joist, while supporting beams form room walls.

4.4. Mono roof truss

A mono roof truss is essentially half of a traditional truss, sloping in one direction. It’s commonly used for creating additional roof tiers, porches. Mono-pitch trusses, resembling right-angled triangles, are ideal for sheds, garages, home extensions.

4.6. Howe roof truss

Made from a combination of wood and metal, the Howe truss is notable for its wide coverage, spanning 6-30 meters. It consists of upper and lower chords connected with vertical and diagonal members, offering strength for large spans.

4.7. Fan roof truss

Usually constructed from steel, the fan truss is a simple, efficient truss with a span of 10-15 meters. It is often used in straightforward applications where simplicity and effectiveness are key.

4.8. King post roof truss

Typically used in smaller residential homes, the king post truss has a central vertical post that provides tension to support the beam below the apex. It spans up to 8 meters and is simple and efficient for smaller structures.

4.9. Queen post roof truss

With a span of around 10 meters, the queen post truss is versatile and reliable. It is one of the simpler trusses, often used across a wide range of buildings, providing a practical solution for medium spans.

4.10. Pratt roof truss

A highly economical and popular choice, the Pratt truss has a span of 6-10 meters. It features vertical and diagonal members that slope towards the center, making it strong and cost-effective for a variety of applications.

5. Distinguish between roof trusses and rafters

5.1. Similarities

- Roof trusses and rafters form the structural framework of a roof.

- They provide essential support to the roof panel and covering, ensuring the stability and integrity of the roof.

5.2. Differences

|

Feature |

Roof trusses |

Rafters |

|

Construction method |

Prefabricated, engineered structures built off-site, delivered for installation. |

Built on-site, requiring carpentry and more manual labor. |

|

Design process |

Computer-generated with precise measurements, ensuring consistency and accuracy. |

Custom-built on-site to fit specific building needs and dimensions. |

|

Cost |

Generally less expensive due to prefabrication, reduced on-site labor costs. |

Typically more costly due to increased labor, material customization. |

|

Delivery time |

Requires lead time for manufacturing, delivery to the building site. |

No delivery needed, constructed directly at the location. |

|

Suitability for remote locations |

Can be challenging to deliver to remote or hard-to-reach sites. |

More suitable for remote locations, as materials can be transported easily. |

|

Attic space |

Limited attic space due to webbing structure, which restricts potential conversion. |

Allows for open attic space, making future conversion more feasible. |

|

Modification flexibility |

Difficult to modify after installation due to the webbing and design constraints. |

Easier to modify or customize, allowing for potential layout changes. |

6. Instruction for roof truss installation

Step 1: Prepare the work area

Begin by ensuring the work area is clear, level, free of debris. Lay out the trusses on the ground, carefully spacing, orienting them according to the layout.

Step 2: Set the first truss

Start at one end of the structure, positioning the first truss on the wall’s top plate, aligning it with the layout marks. Secure it temporarily in place with braces.

Step 3: Install the remaining trusses

Place each truss along the roofline, maintaining proper spacing and alignment. Use temporary braces to hold each truss until they’re all positioned.

Step 4: Secure the trusses

Fasten the trusses firmly to the top plate using suitable nails or fasteners. Proper anchoring is crucial for roof stability.

Step 5: Add bracing

Install diagonal bracing between the trusses to prevent lateral movement, enhance structural stability.

Step 6: Complete roof sheathing

Once all trusses are secured, proceed with roof sheeting, insulation, roofing materials for a durable, weatherproof roof.

Roof trusses play a crucial role in the structural integrity and design of modern buildings, providing strength, stability, and versatility. BMB Steel hopes this article has given you a clearer understanding of what is a roof truss and its functions.

Given the complexities involved, installing roof trusses requires specialized knowledge, so it's always best to hire a professional contractor to ensure your project meets all regulations and is installed securely and safely. For expert advice on the best roof truss solutions for your project at competitive prices, please contact BMB Steel – a leading contractor in pre-engineered steel buildings and steel structures.