Reasons why prefabricated construction is a new trend in 2022

Currently, most investment owners choose prefabricated construction solutions for their projects. Hence, are you curious about what a prefabricated building is? What are the advantages of the prefabricated building? Let’s find out with BMB Steel in the article below.

1. What is a prefabricated building?

A prefabricated building is a type of building in which components such as floors, walls, columns, frames, etc., are precisely dimensioned and manufactured in advance in the factory and then transported to the construction site for assembly.

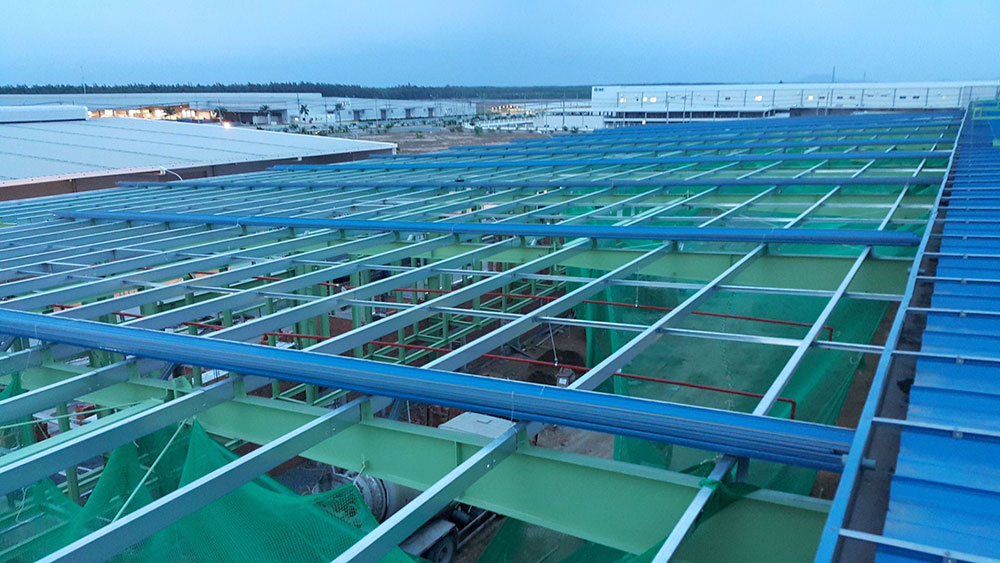

Currently, prefabricated buildings are widely applied in many construction projects of industrial factories, warehouses, manufacturing plants, etc.

2. Construction of prefabricated buildings

Commonly, a prefabricated building includes the following parts:

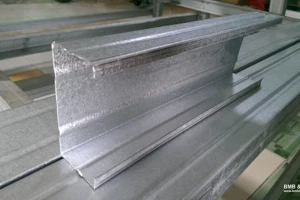

- Pre-assembled frame system: It is made of galvanized steel box to increase durability and aesthetics. Besides, it is subdivided into the structure to facilitate movement and assembly.

- Partition walls, surrounding walls: Usually made of high-quality corrugated iron, capable of heat and sound insulation.

- Roof system: Roofing with anti-rust corrugated iron, anti-thunder, waterproof and soundproof. The thickness ranges from 50mm-100mm.

- Floor: Usually made from specialized floors such as cement floors, concrete floors, etc

- Door system: Made from aluminum and glass or reinforced steel core plastic doors, can be replaced with panel doors depending on business requirements to ensure quality and durability for the project.

- Home accessories system: The bolts connecting the foundation beams, frames, roof frills, roof tiles or drainage pipes, etc.

3. Advantages and disadvantages of prefabricated buildings

Prefabricated buildings become the optimal choice of many investment owners under the following outstanding advantages:

- Lightweight: Steel frame prefabricated buildings are considerably lighter than concrete ones. The pressure on the foundation is also lighter, ensuring safety and durability.

- Quick construction time: The assembly process is simple and easy because the parts are already manufactured. Progress is accelerated 2 to 3 times faster than other solutions.

- Flexible adjustment: Easy to repair and expand because the steel components can be easily removed.

- Cost savings: Because of the fast construction time, the costs of labor, maintenance and raw materials incurred are optimized.

- High aesthetics: The design is diverse depending on the requirements of the investment owens; the materials are artistic.

Besides the outstanding advantages, prefabricated buildings also have some disadvantages that businesses need to note:

- Need large space for construction and assembly.

- Compared to concrete buildings, prefabricated ones are not as sustainable.

4. Construction process of prefabricated buildings

A completed project must have a clear and strict process. The prefabricated construction process includes the following steps:

Step 1: Develop the project’s design ideas

It would be best if you formed an idea for your project and chose the design style you want.

Step 2: Complete the detailed design drawing

Choose reputable and experienced contractors and architects to make detailed and accurate drawings according to your wishes.

Step 3: Prepare the necessary materials and choose a reliable source of raw materials

Based on drawings, prepare all necessary materials and appropriate budget estimates.

Step 4: Choose a highly reputable construction contractor

This step is crucial, and you should choose a contractor with experience and reputation for the optimal completion of the work.

Step 5: Carry out construction, build prefabricated buildings

Prefabricated parts are shipped to the site for assembly based on drawings.

Step 6: Finishing the prefabricated building

Complete and assemble the remaining systems of the building.

5. Vital notes when constructing prefabricated buildings

For conducting the prefabricated construction process smoothly and quickly, investment owners need to pay attention to these factors:

- Choose a reputable, high-quality design and construction contractor.

- Carefully review the data and the materials to be prepared.

- Thoroughly study the construction site.

- Pay attention to labor safety during construction.

6. Some practical applications of prefabricated buildings

BMB Steel has applied prefabricated buildings in many factories, warehouses, and factories. Almost all of these works are evaluated as modern, aesthetic, and cost-effective.

BMB Steel has compiled the most detailed information about prefabricated buildings in the above article. Hopefully, this article will be useful in considering and choosing the type of business. If there is any problem, please freely contact us.