Industrial factory - An outstanding construction solution for enterprises

In the context of industrial development, the number of factories and enterprises has risen considerably to serve the needs of production in many companies. It can be clearly seen that the industrial factory is becoming a trend for many construction contractors by virtue of its convenience, ease of assembly, and cost optimization.

1. What is an industrial factory?

An industrial factory is a large area storing a great number of types of equipment, pieces of machinery, raw materials, etc., for all stages of the company's production, preservation, and transportation process.

In terms of scale, industrial factories are large or small, depending on the demands of the business. Normally, a factory often has a capacity of up to thousands of workers. Based on the type of product, each factory will serve one or many stages in the production process of the enterprise.

2. Two main types of industrial factory

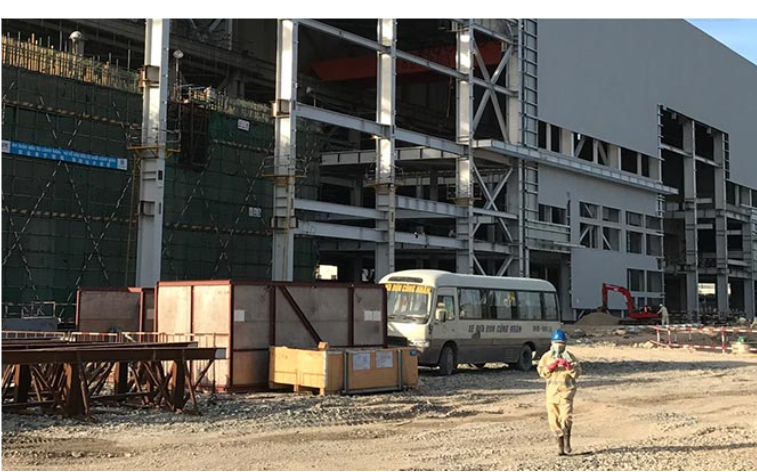

Industrial factories are designed and built-in many different ways. However, among them, there are two main types: pre-engineered steel factory and reinforced concrete factories. Practically, both two types have their own advantages and disadvantages. Depending on the production goals, the enterprise will choose the most appropriate and optimal construction plan.

2.1 Pre-engineered steel factory

Pre-engineered steel industrial factories are built and assembled from raw materials and steel structures. Before construction, the factory will be fully conceptualized and designed by the engineering team to complete and come up with the most optimal plan in terms of material and labor costs for the business.

There are some significant advantages of pre-engineered factories such as:

- The primary material is steel, which is a durable and long-term value material. Besides, its assembly and connection process between parts is also relatively easy by using welding, bolts, and screws.

- Easy erection: steel is a lightweight material, which can be easily transported on any terrain, including mountainous or uneven terrains.

- Low cost of erection: Lightweight and easiness to transport are the reasons why pre-engineered industrial factory projects are widely chosen for many significant projects

- Minimize the cost and the number of workers

- Save time: Compared with other solutions, pre-engineered factories take at least 2-4 weeks to be put into use. This helps to speed up the work progress as well as save considerable time for businesses.

2.2 Reinforced concrete industrial factory

The reinforced concrete industrial factory is completed and constructed with two main materials: concrete and reinforcement. This type of construction is widely chosen by many people because of its superiority and certainty. Concrete factories are usually built of bricks with a thickness of 10-20cm, and the structures are connected by columns, beams, and sturdy steel frames. This type of construction is often favored by outstanding features such as:

- Durable

- Good bearing capacity

- Effective heat and noise resistance

- Long-term using

- Good resistance to corrosion and fire

3. Application of industrial factory

By virtue of these outstanding advantages, industrial factories are often chosen by many large-scale companies and enterprises as a place to carry out production and business processes in many different fields such as garment and textile, assembling electronic components, producing goods, food, automobiles, machinery, equipment, etc.

Additionally, industrial factories are applied in agriculture effectively with many projects of garden houses growing flowers and vegetables in Sapa, Da Lat, etc. This type of factory is the key factor assisting farming households because of its high economy, ease of assembly, and ease of creating a suitable environment in terms of temperature and light for optimal growth of plants and animals.

Furthermore, industrial factories are extensively applied in other projects such as supermarkets, shopping centers, markets, sports halls, exhibition areas for events, etc.

4. Some popular industrial factory models

Currently, industrial factories gradually appear in many places with different scales. The scale of the factories depends on the area, construction goals, and the demands of the business. In general, we can classify industrial factories into 3 types:

4.1 Small-scale factory

Regardless of the miniature land area, small factory projects show a lot of efficiency for businesses, such as taking advantage of the land area, reducing the cost of renting or buying land, and meeting the need for compactness to fit the scale. In addition, to minimize expenses, factories often take advantage of the building frame to renovate into offices. Simultaneously, that design helps the operation between factories and offices to be unified and efficient.

As small-scale pre-engineered factories have a fast and professional construction time, high technology application, lightweight steel frames, they show a lot of advantages in construction. Typically, this type of factory creates an open and bright space with windows and roof doors to absorb daylight. Besides, this helps to save energy and ensure the quality of the project when it is put into practice. These above characteristics make small pre-engineered steel factories become the most often solution used for factories for the packaging industry.

4.2 Medium-scale factory

For medium and large enterprises, medium-scale factory models will be the optimal choice because these projects can meet the needs of many objects. A larger area will take advantage of the simple, comfortable, and modern design to get the highest working productivity.

In addition, with a large usable area, a medium-sized industrial factory can be built and assembled with larger production lines but still have enough room for moving in the workshop space. Moreover, the combination of factories and offices will help businesses maximize area, costs and create a high level of professionalism.

The medium-scale pre-engineered steel factory has a simple but spacious design, using a relatively large structure to make the space open and wide, making the most of the space. This project is suitable for the textile industry or food production, etc.

4.3 Large-scale factory

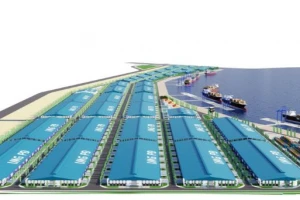

Large-scale factories usually appear in developed countries, but in recent years, this type of factory has gradually appeared in Vietnam. Usually, these projects often have a very large area because businesses often require a large space for vehicles and machines to easily move inside the factory in the most convenient way.

Large-scale pre-engineered factories are often built in clusters or built close together to optimize transportation costs as well as ensure a smooth and easy production process. This type of workshop is often applied in large-scale manufacturing industries such as heavy metal industries, automobile manufacturing, electronic component manufacturing, accessory manufacturing, etc.

In the article above, BMB Steel has provided you with fundamental information about industrial factory projects in Vietnam. Hopefully, businesses and enterprises have had an overview to choose the most suitable type of factory for their production and business goals.