Three-story house's strip footing: Safe construction handbook

- 1. Construction of 3-story house's strip footing

- 2. How to build a sustainable strip footing for 3-story houses

- 3. Experience in safely constructing 3-story house’s strip footing

- 4. Common problems with 3-story house's strip footing

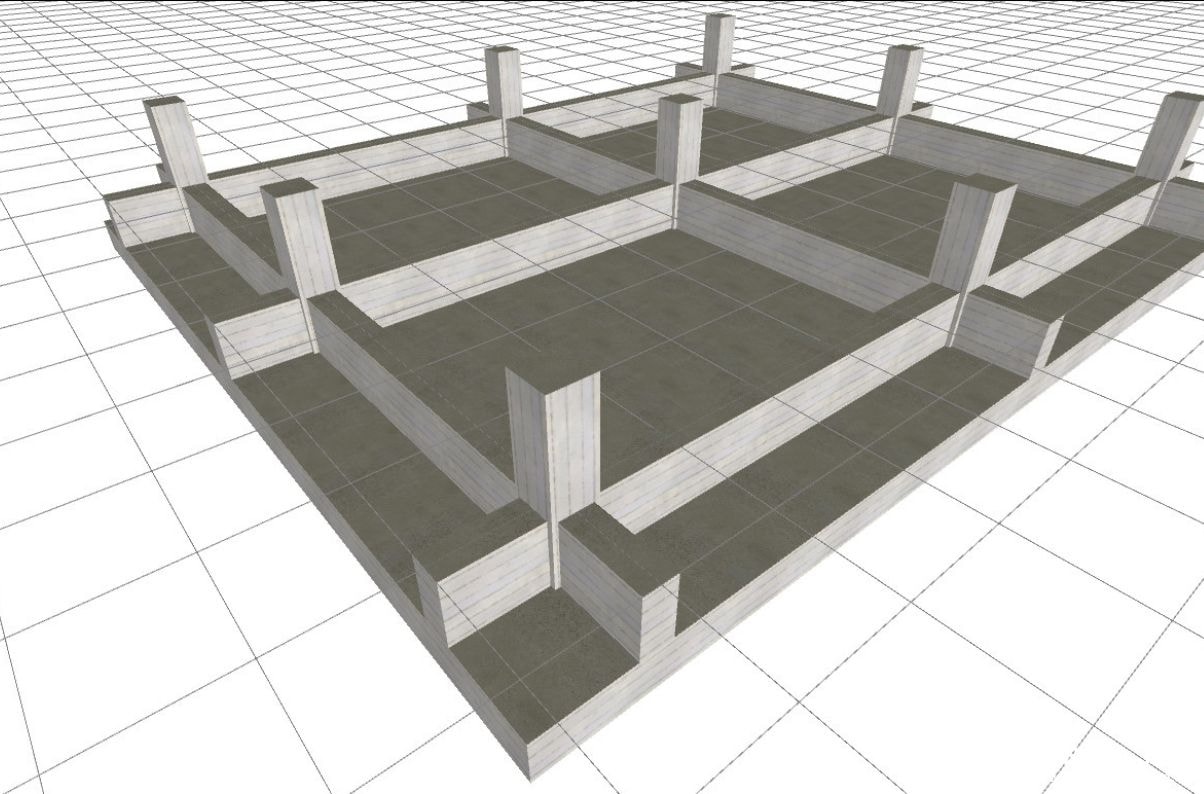

Among the types of foundations being used today, using 3-story house’s strip footings is considered the best solution to help the building withstand load. However, during the construction process, attention also needs to be paid to safety factors. Therefore, in this article, we will share with you knowledge about the design organization process and current experience in constructing quality and safe strip footings.

1. Construction of 3-story house's strip footing

To ensure the safety and quality of the 3-story house's strip footing structure, it is necessary to follow the correct process and ensure accurate design standards in terms of load, foundation depth, construction materials...

1.1 Safe construction organization process

The process of organizing strip footing construction needs to fully ensure the following stages:

1.1.1 Clearing the site to prepare for strip footing construction

To prepare for the construction of strip footings, site clearance is needed. Some preparatory work at this stage includes:

- Prepare human resources, raw materials, and machinery.

- Estimate adequate materials in quantity and quality such as steel, cement, stone... To ensure that steel structure can best withstand the load.

- Construction equipment and machinery also need to be properly prepared to ensure the construction process goes well.

1.1.2 Ground filling

The next step after site clearance is to level and clean the site. Cleaning the land for strip footing construction will help the construction process go smoothly and quickly. Accordingly, this area needs to be handled as follows:

- Based on the available design, it is necessary to determine the construction axis on the ground level of that land.

- Dig the foundation according to the identified construction axis.

- Clean the newly dug foundation area so that the area is in the driest condition. If water appears in the foundation pit, it needs to be drained so that the foundation is dry.

1.1.3 Reinforcement work

Reinforcement work needs to be organized flexibly and quickly. The reinforcement part can be processed directly at the strip foundation construction area or the factory depending on the conditions to still ensure the required quality and quantity.

During the assembly of reinforcement, mechanical methods or welded joints can be used. However, it is necessary to arrange according to the drawings of the 3-story house's strip footing structure. The purpose is to avoid the situation where the installer based on experience causes the bearing of the steel to be in the wrong direction or reduces the effectiveness of the reinforced structural system.

Steel bars need to meet quality standards and have the toughness to make them more convenient for processing and bending. In addition, steel is also processed according to the following steps:

- Processing according to technical requirements.

- Lay concrete or bricks to create space with the foundation soil.

- Place the pallets on top of the concrete or brick lining.

- Place steel in the strip footing.

- Place steel in the foundation beams.

- Place steel waiting for concrete pouring.

1.1.4 Formwork work

Formwork for the foundation of a 3-story house or any other project is placed according to a predetermined steel grid. When installing formwork for the foundation concreting process, it is necessary to choose formwork to suit each type of foundation and ensure technical standards during construction.

The bars supporting the ground must be placed on wooden boards at least 4cm thick to reduce the horizontal force when pouring concrete. In addition, the center of the foundation and columns must be determined at the correct elevation to ensure accuracy during structural construction. At the same time, it is also necessary to choose a type of formwork that can withstand the force even when using a floor beam machine to avoid the condition of the formwork coming apart when pouring concrete.

1.1.5 Concrete work

Nowadays, the process of pouring concrete has become much simpler because of the participation of mechanical equipment. However, to make the process go smoothly and quickly, you need to pay attention to the following points:

- Stone, gravel, and sand materials used for mixing need to be of the right size to ensure quality, with no bubbles or voids when the concrete is finished.

- The concrete cross-section is trapezoidal, with a small slope so that it does not waste time on joining the formwork on the surface, but only needs to join the two sides. After pouring concrete, it is necessary to quickly use a tamper or table compactor to compact the concrete so that it does not flow and is strong.

- During foundation construction, it is necessary to avoid flooding the foundation pit with water. If the concrete is flooded, it will reduce the bond of mortar and cement and reduce quality standards.

- After pouring concrete, you need to cover it carefully and check the corners to see if they are cracked or not. If any, it needs to be treated immediately to avoid nail deformity or wrong size, which can affect the entire strip footings.

1.2 Principles of strip footing design for 3-story houses

To ensure the durability of the 3-story house's strip footing after construction, you need to pay attention to the following principles:

1.2.1 Load and calculation

Load is an important factor to consider before deciding to build a strip footing for a 3-story house. Calculating the load of the house will help decide to choose the appropriate type of strip foundation.

For houses with a large area of over 100m2, strip footings are the top priority because of their moderate cost and good durability and bearing capacity. In addition, investors also need to consider their long-term needs whether they want to build a 4th or 5th floor or not. Thus, there is a direction to design the strip footings so that it has the maximum bearing capacity.

1.2.2 Required depth for strip footing

Normally, the strip footings for a 3-story houses with even settlement will be less than 1.5m wide. Construction work is also quite simple, not too demanding but helps save costs.

Furthermore, for projects with an area of over 300 square meters, strip footings are still the perfect choice. The average depth for strip footings is usually from 2 to 2.5m, which will help the project become more solid.

1.2.3 Select strip footing construction material

During the construction of the strip foundation, it is necessary to prepare materials such as steel, sand, cement, stone, and melaleuca piles. Depending on the area, specific data will be given just enough to avoid shortage or excess causing waste for the homeowner.

Besides, it is also important to note that the type of steel used to make the strip footings need to be chosen with the highest rust resistance. Because it is in a system that must bear forces from the outside as well as the entire house's downward force. Therefore, it is necessary to ensure the correct quantity and quality according to the drawings to ensure project efficiency.

1.2.4 Comply with relevant standards and regulations

In addition, the standards for foundation size, column, beam, footing, and steel belt arrangement in the strip footing drawing also need to be properly followed. Technical specifications on raw materials also need to ensure high accuracy to help the strip footing construction process achieve optimal efficiency.

2. How to build a sustainable strip footing for 3-story houses

To build a sustainable strip footing for a 3-storey house, it is necessary to have procedures, implementation techniques and thorough inspection after the finished product.

2.1 Arranging the construction process

The foundation construction process needs to be arranged in clear steps, in the right time, and the right process. From preparing the site, making reinforcement, trying to mix and exchange concrete... all require technical calculations to ensure project quality meets standards, high durability, avoiding cracks or wrong parameters.

2.2 Construction techniques to ensure sustainability

In the process of making strip footings, the builder's technique is extremely important. Each stage requires unique techniques to ensure the best foundation construction process. Especially in the stage of making reinforcement, it is necessary to ensure that the weld joints meet standards. Reinforcing steel must be bent and cut according to the design shape.

2.3 Checking the mobility and safety of the strip footing

After completing the construction of the strip footings, it is necessary to regularly check thoroughly and closely to ensure that the footings do not have any errors. If so, it needs to be promptly handled to ensure optimal finishing of the strip footings.

3. Experience in safely constructing 3-story house’s strip footing

It can be said that the construction of the foundation greatly determines the durability and safety of the house. Because the foundation is very difficult to repair and renovate. In the long run, to get a quality foundation for your home, investors and homeowners need to note the following points:

3.1 Preparing construction ground

The stage of preparing the construction site is quite important. It determines whether the construction process takes place quickly and securely or not. The faster and tidier the site is cleared, the faster the construction of the strip foundation will take place.

3.2 Choosing a reputable construction company

Besides preparing the ground, choosing a reputable construction unit also largely determines the durability of the strip foundation. A reputable and experienced unit in making strip footings will help the investor calculate and design the foundation according to requirements.

At the same time, provide quick solutions to handle problems. In addition, they can also arrange the construction process scientifically, the materials used for the foundation are listed just enough, without wasting money and time for the homeowner.

Currently, BMB Steel is a leading company in the design and construction of projects ranging from housing, factories, corporate offices... Therefore, the construction of the 3-story house's strip footings will be carried out professionally by the unit, bringing the best results to investors and homeowners.

With many years of experience in the profession, we have implemented many large and small projects at home and abroad. Currently, BMB is implementing many large projects, the most typical being the Zhong Ju factory project with an area of 21,000 m2 with an estimate of about 1,100 tons of steel to be implemented within 100 days.

With professionalism in our expertise and a spirit of continuous learning and work, we are committed to bringing maximum satisfaction in quality and progress to our clients.

3.3 Closely supervising construction

In addition, to safely construct 3-story house's strip footings, strict construction supervision is required. Currently, there are many construction units, but not all of them are reputable.

Many companies that want to shorten time or do things quickly can take actions such as reducing materials, cutting down on the implementation process, or doing things incorrectly. This will cause a lot of danger to the quality of the foundation in the long run.

The project may face the risk of not being able to bear enough load according to the design, easily cracking and collapsing after a period of use.

Therefore, if you do not feel confident, the investor needs to plan strict construction supervision. This helps limit the above situations, while ensuring that raw materials are not wasted or lost, causing economic loss as well as the quality of the strip footings.

3.4 Checking the quality of the strip footing

After completing the construction of the strip footings, the investor needs to carefully check the quality of the footings. If there are any unsatisfactory issues or the tape nail is cracked or peeling, you need to ask the construction unit to quickly handle it to ensure the quality of the footings.

4. Common problems with 3-story house's strip footing

Although the 3-story house’s strip footing is the most optimal solution today, during the construction process, if the techniques and design process are not correct, the following problems may occur:

4.1. Fixing cracks

If a strip footing subsides or cracks after a period of construction, it may be due to reasons such as high soil settlement, project load exceeding the original foundation design, poor quality of foundation construction process

In case of small cracks, further monitoring can be done. In addition, if the cracks are too large, you should immediately report them to a reputable construction team to survey and come up with the best solution.

In addition, if you want to prevent this situation from happening when you are planning to build a 3-story house, you should prepare the right construction materials and design the structure to suit the requirements and uses. Especially choose a reputable construction unit to ensure project quality.

4.2. The solution for strip footing not being hard enough

Strip footings not being hard enough are also a problem that easily occurs when doing manicures. This situation is often due to the initial design not matching the actual load of the building. Or it could be because the construction process does not ensure standards of materials and implementation techniques.

In this situation, reinforcement measures are needed. For example, expanding the base of the foundation or switching from a strip footing to a raft foundation. However, for the best solution, you should contact the construction units to find out the exact cause and have thorough remedies.

The information when building a strip footing for a 3-story house to ensure quality and safety is above. It can be said that building a strip footing according to the correct process and design will help ensure the safety and sustainability of the project in the long term. This is a very difficult item to repair, so you need to be careful during construction. If you are looking for a reputable unit to build a strip footing or the entire house, please contact BMB Steel immediately. With the motto of promoting project quality coupled with completion time and aesthetics. We are committed to bringing clients the maximum satisfaction.