Bolted connections used in pre-engineered steel buildings

Pre-engineered steel construction has become a popular choice in the modern construction industry due to its numerous advantages. These structures are composed of various steel components that must be securely connected to ensure structural stability and integrity. One crucial element in connection systems in pre-engineered steel buildings is the use of bolted connections. In this article, we will explore the significance of bolted connections and their advantages in the construction of pre-engineered steel buildings..

1. A brief introduction to the bolted connection in pre-engineered steel buildings

There are a number of different connection methods which are used in pre-engineered steel buildings. They will be discussed in the following part of this article.

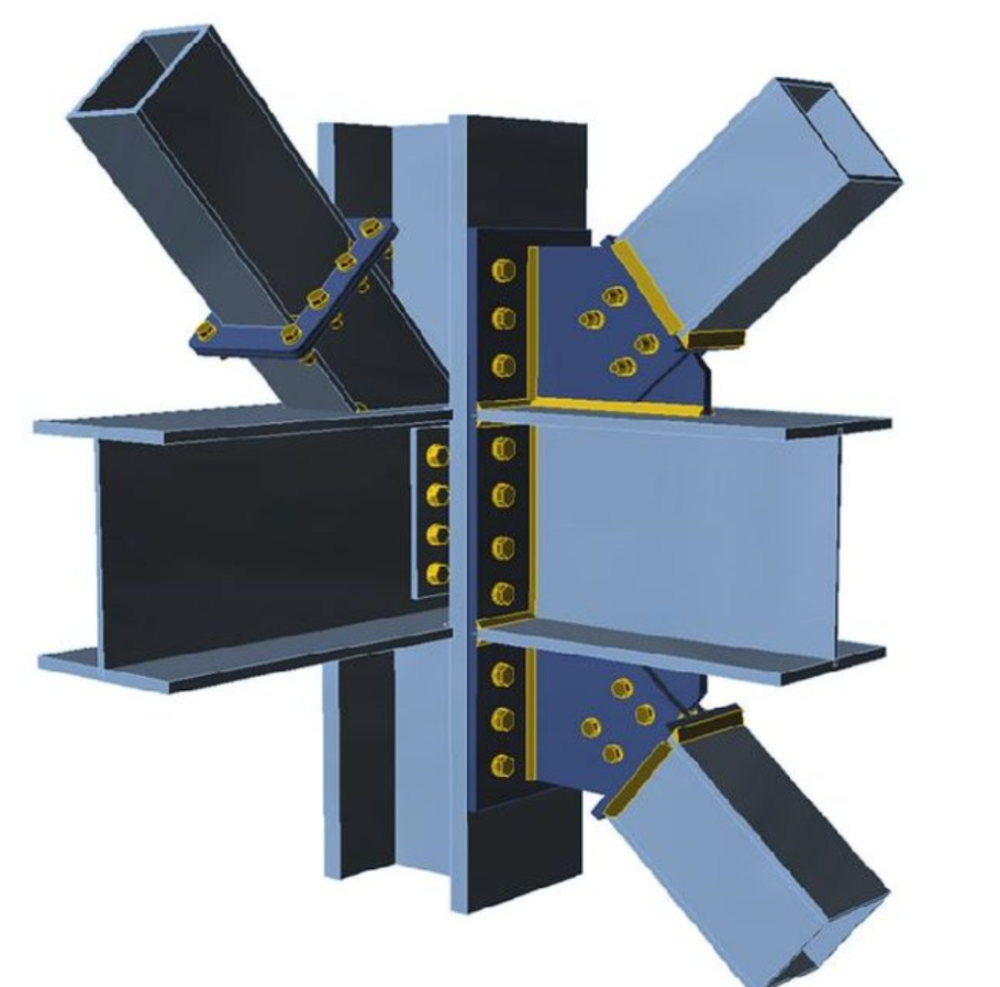

A bolted connection refers to a method of joining two or more structural components or elements using bolts. It is a widely used technique in construction and engineering to securely fasten materials together to form a structurally sound assembly, at the same time, it is flexible in structuring connection types that transmit different types of forces such as moment, axial force, shear force, and torsional force to meet different structural, load-bearing and usage requirements.

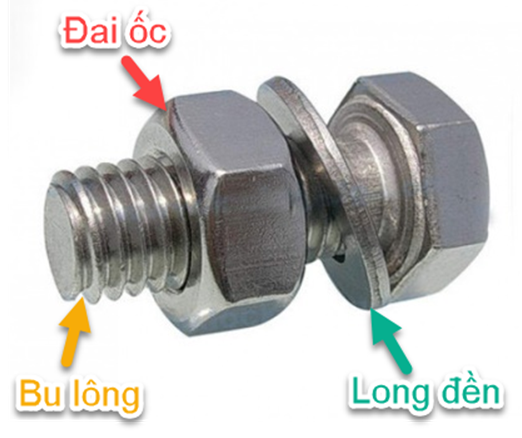

In a bolted connection, holes are typically drilled or pre-punched in the components to be joined. Bolts, which are threaded cylindrical rods with a head on one end, are inserted through the aligned holes. Nuts are then threaded onto the exposed ends of the bolts and tightened to create a clamping force. This clamping force compresses the components together, creating a strong and rigid connection. The intermediary between the bolt and the nut is the washer, which has the effect of distributing pressure evenly on the parts to help tighten the connection or prevent vibration to prevent the nut from loosening.

2. The importance of bolted connections in pre-engineered steel buildings

Advantages of bolted connections in pre-engineered steel buildings include:

- Strength and load transfer: Bolted connections provide exceptional strength and load transfer capabilities. The bolts, typically made of high-strength steel, are designed to withstand significant tensile and shear forces. This allows for the efficient transfer of loads between connected members, ensuring the overall stability of the structure.

- Easy installation and assembly: Bolted connections are relatively easy to install and assemble on-site. The pre-drilled holes in the steel components align precisely, simplifying the connection process. Unlike other connection methods, such as welding, bolted connections require minimal specialized equipment and can be quickly tightened using torque wrenches.

- Adjustability and flexibility: Bolted connections offer adjustability and flexibility during the installation and future modifications of pre-engineered steel buildings. They allow for easy disassembly and reassembly, enabling changes in building layouts or the addition of new components without compromising the structural integrity of the existing structure. This adaptability is especially beneficial in situations where building expansion.

- Quality control and inspections: Bolted connections facilitate enhanced quality control and inspections during the manufacturing and assembly stages. Each bolted connection can be visually inspected for proper alignment and tightened, ensuring consistent and reliable performance of the building.

- Cost-effectiveness: Bolted connections offer cost advantages over other connection methods like welding. The installation process is typically faster, reducing labor costs. Additionally, the ease of disassembly and reassembly allows for potential cost savings during building modifications.

- Protects the surface of the parts when tightening: The structure of the bolt includes the main bolt and nut, in addition to an intermediate washer or washer, which helps protect the surface of the parts when tightening. This time distributes the pressure of the nut more evenly, helping to tighten the connection. In particular, the washer also has the effect of providing anti-vibration ability, helping the nut not loosen during use.

- Reduce packaging and shipping costs: Packaging volume is large, space occupied is optimized, and transportation is easy because the size is not too large, helping to reduce packaging and shipping costs.

- The construction process is quick and accurate: Bolt holes are machined at the factory, ensuring the accuracy and compatibility of bolts and holes, helping the construction process go smoothly. Fast and accurate.

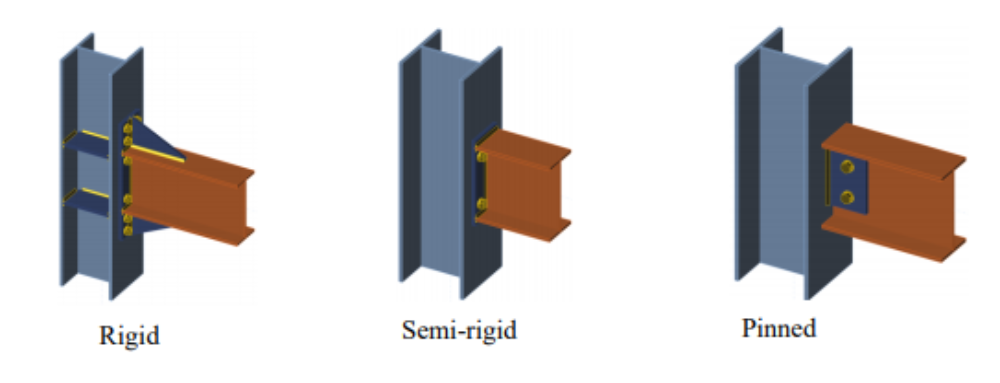

- Flexible use of different types of links: Bolt links can be designed and structured to transform into different types of links such as joints, mounts, or semi-mounts, helping to flexibly use different types of connections. Different connections in pre-engineered steel buildings to meet load-bearing requirements and diverse uses according to each area of the building, optimizing costs.

3. Different categories of bolted connection used in pre-engineered steel buildings

Bolted connections can be classified based on various factors, including their load-carrying capacity, the behavior of the connected elements, and the level of redundancy.

Here are some common classifications of bolted connections:

3.1 Classification based on resultant force transferred

- Tension connections: These connections primarily transfer tensile forces along the axis of the bolts. They are designed to resist pulling forces and keep the connected members in tension.

- Shear connections: Shear connections transfer shear forces perpendicular to the axis of the bolts. They are designed to resist sliding or shearing of the connected members.

- Combined tension and shear connections: These connections transfer both tensile and shear forces simultaneously. They are designed to handle the combined effect of tension and shear.

3.2 Classification based on type of force

- Axial connections: Axial connections transfer forces along the axis of the bolt. They primarily handle tension or compression forces applied parallel to the bolt axis.

- Eccentric connections: Eccentric connections handle forces that are not aligned with the axis of the bolt. These connections can experience a combination of tension, compression, and bending moments.

3.3 Classification based on force transfer mechanism

- Bearing connections: Bearing connections transfer forces through direct contact between the bolt and the connected elements. The load is transmitted through the bearing area.

- Friction connections: Friction connections rely on the frictional resistance between the connected surfaces to transfer forces. The clamping force generated by the bolted joint maintains the frictional resistance.

- Preloaded connections: Preloaded connections involve applying a controlled initial tension, or preload, to the bolts before external loads are applied. The preload ensures that the connection remains tight and helps prevent loosening or slipping under the applied loads.

3.4 Classification based on strength of connections

- Simple connections: Simple connections are typically used in structures where the connected elements are designed to be the weakest link. The bolts are designed to carry a portion of the applied load, while the remaining load is distributed to the connected elements. Simple connections are commonly used in light to moderate load applications, such as in light steel framing or small-scale structures.

- High-strength connections: High-strength connections are designed to have sufficient strength to carry a significant portion of the applied load. The bolts in these connections are designed to resist a substantial amount of the load, reducing the reliance on the connected elements. High-strength connections are commonly used in heavy structural applications, such as in large-scale buildings, bridges, or industrial structures.

Above is information regarding bolted connections used in pre-engineered steel buildings. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.