Connection systems in pre-engineered steel buildings

Pre-engineered steel construction has become a popular choice in the modern construction industry due to its numerous advantages. These structures are composed of various steel components that must be securely connected to ensure structural stability and integrity. In this article, we will discuss the importance of connection systems in constructing safe and durable structures and list some common connection systems used in pre-engineered steel buildings.

1. A brief introduction to the connection systems in steel structure

Steel structures are composed of several steel components such as columns, beams, trusses, bracing, etc. Each of the components has particular characteristics and advantages. They are connected together to form a complete and functional steel building or infrastructure.

Connection systems in steel structures are the systems of joints used to join steel components together. These connection systems are designed to ensure the structural integrity, stability, and load-bearing capacity of the steel structure.

There are a number of different connection methods which are used in pre-engineered steel building. They will be discussed in the following part of this article.

2. The importance of connection systems in pre-engineered steel buildings

The connection systems play a vital role in pre-engineered steel buildings. Here are some key roles of connection systems in pre-engineered steel buildings:

- Structural stability: Connection systems provide the necessary stability to the overall structure by joining different steel members. They ensure that the building can withstand vertical loads, such as the weight of the structure itself, as well as lateral loads, including wind and seismic forces. Properly designed and executed connections distribute these loads efficiently throughout the building, preventing localized failures and ensuring overall stability.

- Load transfer: Connection systems facilitate the transfer of loads between steel components. They enable the distribution of forces, such as gravity loads, live loads, and wind loads, from one component to another, ensuring that the structure can safely carry and distribute these loads to the foundation. Effective load transfer through connections minimizes the risk of overloading individual members and helps maintain the structural integrity of the entire building.

- Rigidity and stiffness: Connection systems contribute to the rigidity and stiffness of the structure. They provide the necessary connection points that allow steel members to act as a cohesive unit, resisting deflection and maintaining the overall shape of the building. The rigidity provided by connections enhances the building's performance under lateral loads, improves its resistance to vibrations, and minimizes deformations that can affect the functionality and aesthetics of the structure.

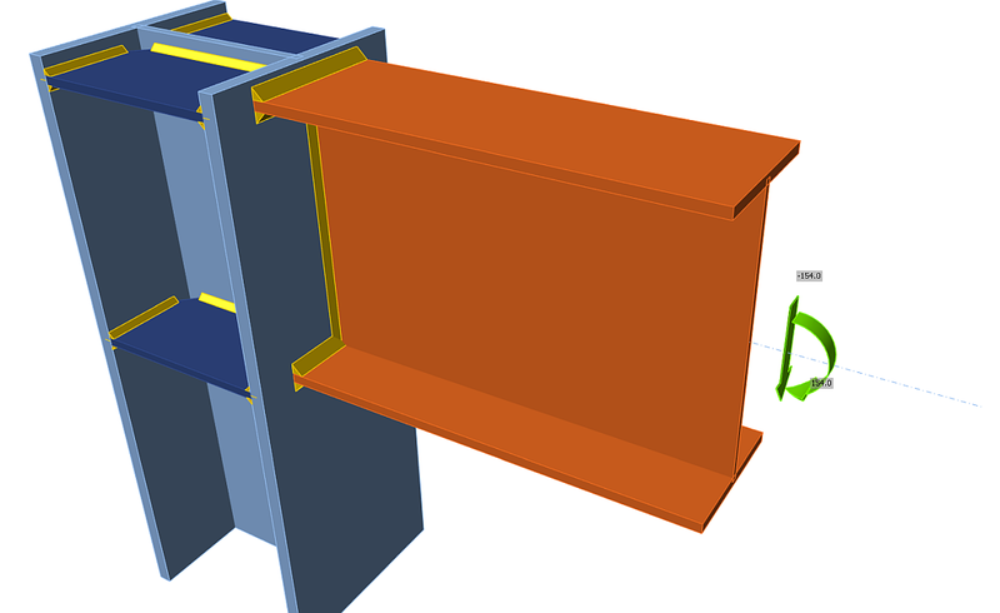

Integrated pre-engineered steel structure with rigid connection - Safety and durability: Connection systems are critical for ensuring the safety and long-term durability of pre-engineered steel buildings. Properly designed and executed connections reduce the risk of structural failure, excessive movement, or displacement during extreme events like earthquakes or high winds. Robust connections also contribute to the building's resistance against corrosion, fatigue, and other environmental factors, enhancing its lifespan and minimizing maintenance requirements.

- Construction efficiency: Connection systems in pre-engineered steel buildings are designed to facilitate efficient and cost-effective construction processes. Connection systems in pre-engineered buildings often utilize standardization and prefabrication techniques. They allow for faster assembly and erection of steel components, reducing construction time and labor costs.

In general, properly designed and executed connections are essential for the overall performance and longevity of these buildings, providing a safe, reliable, and cost-effective solution for construction of pre-engineered steel buildings.

3. Common connection methods used in pre-engineered steel buildings

Here are some common connection methods used in pre-engineered steel buildings:

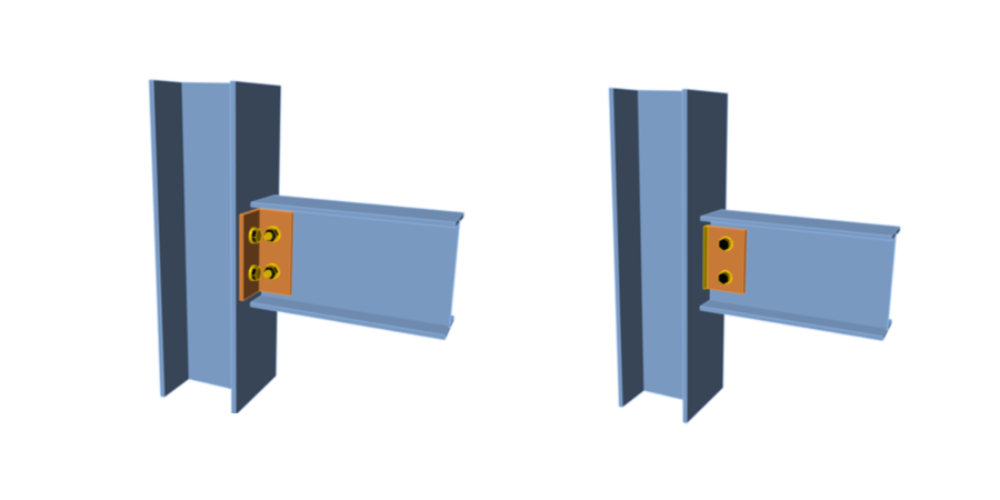

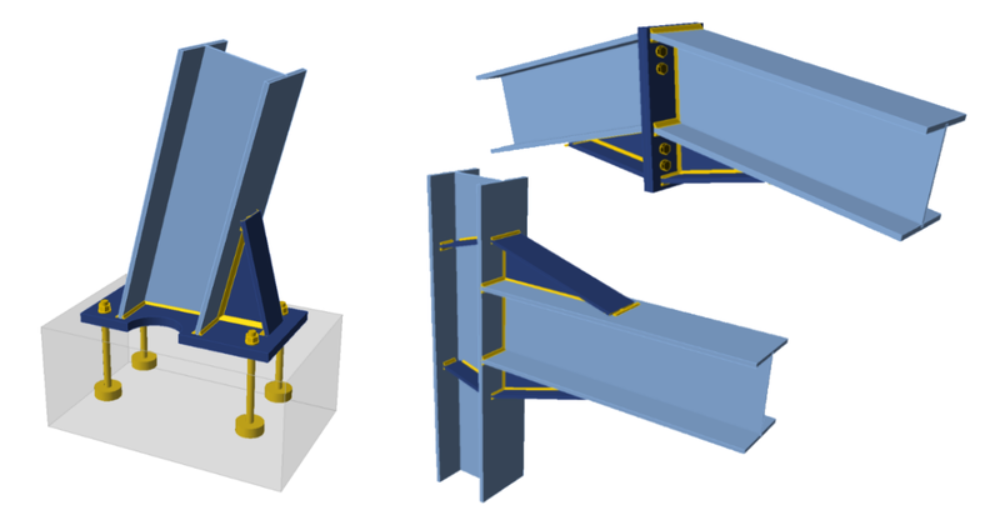

3.1 Bolted connections

Bolted connections are widely used in pre-engineered steel buildings due to their ease of installation, adjustability, and versatility. High-strength bolts are used to connect steel components by pre-drilling holes and inserting bolts through them. Nuts are then tightened to achieve the desired connection. Bolted connections offer advantages such as simple installation, the ability to disassemble or modify the structure if needed, and high load-carrying capacity. They are commonly used for connections between steel columns, beams, and bracing members.

3.2 Welded connections

Welded connections provide a strong and permanent bond between steel components. Welding involves melting and fusing the steel members together using heat, creating a continuous connection. Welded connections offer excellent structural integrity and rigidity, making them suitable for connections in situations where high load-carrying capacity and resistance to bending and torsional forces are required. Welded connections are commonly used for connections between steel beams and trusses. However, it should be noted that welding requires skilled labor and may be challenging to modify or disassemble.

3.3 Shear connections

Shear connections are utilized to transfer lateral loads, such as wind or seismic forces, between steel components. These connections are designed to resist the shear forces acting on the structure and ensure its stability under lateral loads. Shear connections are crucial for maintaining the overall stability and rigidity of the pre-engineered steel building, particularly in regions prone to high wind or seismic activity.

3.4 Moment connections

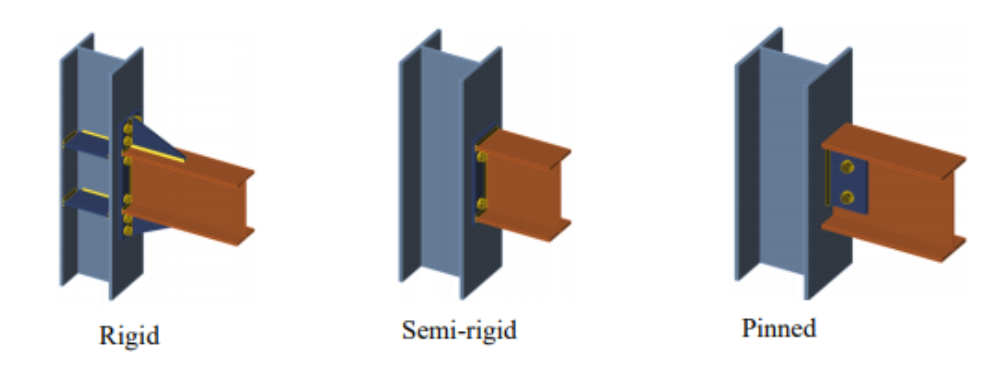

Moment connections are essential for transferring bending moments between steel members, allowing them to resist both vertical loads and moments. These connections provide rigidity and stiffness to the structure, enabling it to withstand bending and torsional forces. Moment connections are commonly used in rigid connections which restrict rotation between the connected members. Two types of rigid moment connections are typically permitted: fully restrained connections and partially restrained connections.

Above is information regarding connection systems in pre-engineered steel buildings. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.