Reasonable small factory design to optimize the use area

Many manufacturing companies widely choose small factory designs. Because of the small workshop design functions, it is suitable for the use purpose by bringing high efficiency. The fact that you do not choose the right factory for the operation of your business will waste capital and time. Let's find out in detail how the small factory design has outstanding features that businesses choose to use this model.

1. Special features when designing a small factory

Design a small factory that uses quality materials. However, the price for small factories is very reasonable for small production enterprises to make the most of the factory area without waste. Moreover, it helps businesses ensure the production process without spending too much money to build.

Small factory design has typical models such as corrugated iron walls and roofs, steel frames with a corrugated iron roof, or high steel frames with a wind roof.

- Design features of small workshops with corrugated iron walls and roofs: There is little ventilation for a closed design workshop model. It is necessary to use a lot of LED lights but to effectively use the heat-insulating corrugated iron as well as create a ventilation space to create a comfortable production environment.

- A small factory with a steel frame with a corrugated iron roof has the following characteristics: The steel frame system of the small factory will use 2-layer painted steel to ensure durability over time. The design slope of the corrugated iron roof is from 15-20%; in addition, there is a layer of stormproof corrugated iron above the non-insulated type D.

- Small factory design with a high steel frame with roof: The wall is designed and built more elevated than other small factory models. Thus, it helps keep the factory ventilated without mold and reduces the cost of installing a cooling fan.

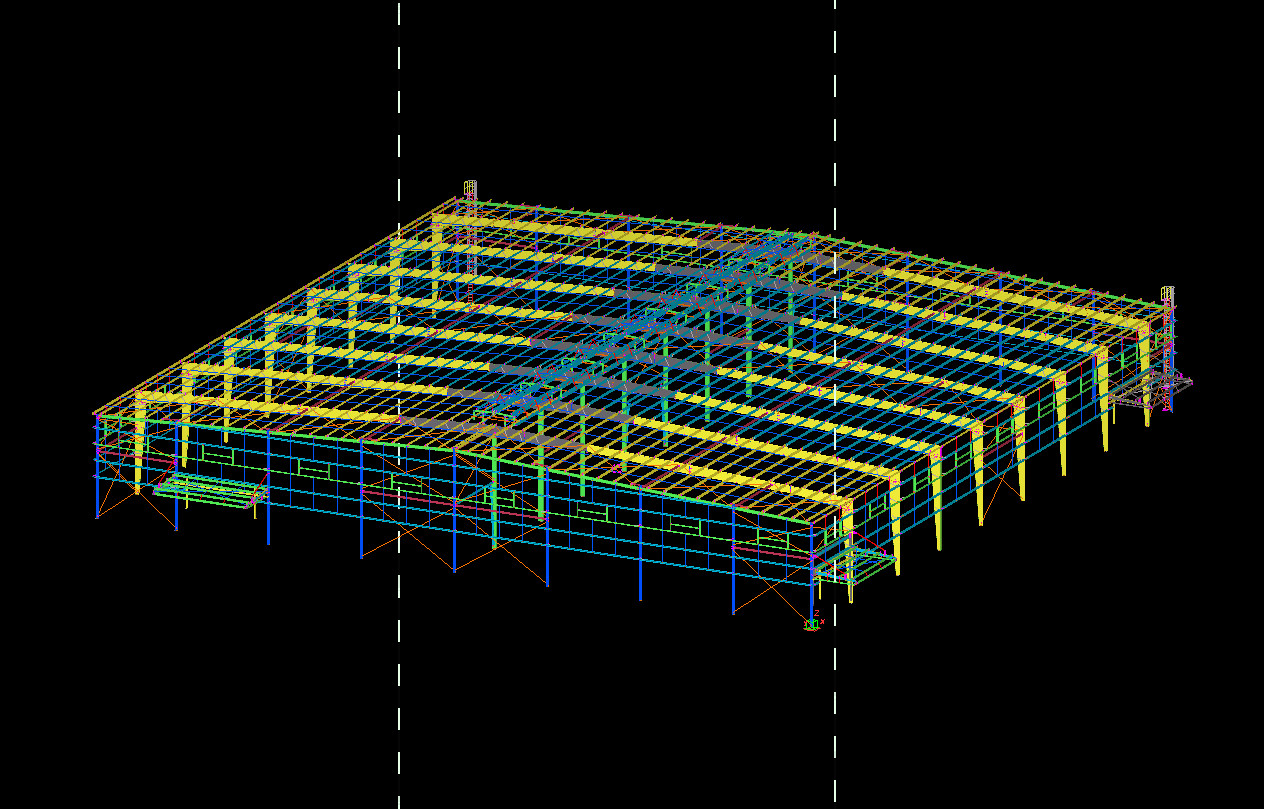

2. Small factory structure

To build a small factory model for businesses to operate, it is necessary to have the following construction stages:

- Building the foundation helps reduce the upper frame load to the ground.

- The bolted secondary structure helps connect the foundation and the main steel frame of the small workshop.

- Steel frames will be H-shaped; in addition to more special models, we can use round shapes.

- The corrugated iron roof used to make the roof, trusses, beams, and purlins is the secondary structure to help the factory have sufficient safety and durability. Moreover, it creates the optimal working environment for workers with a simple and airy design.

3. Advantages of small factory

Small factory design has many outstanding advantages that bring many benefits to businesses.

- Unused space will not be wasted. Small factories are used for parking, storing goods, storing raw materials, and processing factories. Besides, flexibly changing the location of parts of the factory to suit different purposes.

- Cost savings by designing a small workshop, quick assembly, and construction in simple steps. In addition to saving space, the small workshop is uncomplicated to repair and renovate.

- The design of the small workshop is simple but highly durable, and it is easy to build a workshop on soft ground. Small factory samples also limit the fire and explosion.

4. The business which is suitable for choosing a small factory

Small and medium-sized manufacturing companies or businesses should use the small factory model. This helps businesses save on factory rental costs.

The construction of a small factory in size or scale will depend on the operation of the business. For example, there are many factory sizes of 100m2, 200m2, 500m2, etc. The small-size models help to optimize costs for small and medium enterprises.

5. Things businesses need to keep in mind when choosing to build a small factory

- For the design of a small factory, although it saves space, it also needs a full range of functional parts. The parts that need to be arranged scientifically create a reasonable space during use.

- When building, it is advisable to take advantage of natural light and ventilation to create a cool space.

- Although the factory is small in size, the construction also needs to pay attention to the aesthetics.

- Choosing the location to build the factory does not affect the surrounding area and the factory's operation.

- Considering the ecosystem is even more crucial when designing a small factory.

- Pay attention to potential risks such as deformation of the factory structure and possible collapse of the work or work accidents.

We hope our sharing will help you understand in detail the practical small factory design to optimize the area used for the business. With the characteristic of small factory design, it will bring great value to the production activities of enterprises in the future.