Things to know about load-bearing steel frame structures

Load-bearing steel frame structure with outstanding features is the first choice of business owners in the construction of projects. For new businesses, information about this type of structure is quite limited. Today, in the article below, let's learn what you need to know about bearing steel frame structures with BMB Steel.

1. What is a load-bearing steel frame structure?

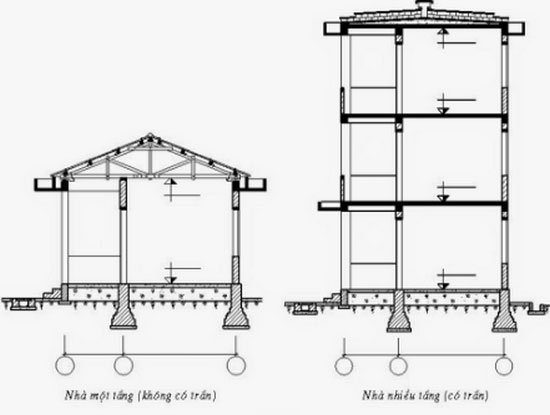

A load-bearing steel frame structure is a type of structure in which horizontal and vertical loads pass through the beam to the column, where columns, braces, and beams combine to form a solid space system that brings sustainability to the building.

Compared with structures from other materials, the bearing steel frame structure has better rigidity, durability, stability and shock resistance. Along with the above outstanding features, the pre-engineered steel frame structure also helps contractors save material costs, small house weight, and flexibility in expanding the area to help good ventilation and ensure sound insulation.

2. Advantages of building load-bearing steel frame structure

2.1 High reliability and bearing capacity

Because steel has the greatest strength of all materials, steel structures have noteworthy bearing capacity. They are less prone to deformation during use. In addition, steel is evaluated as the most elastic and ductile material with precise is as calculated assumptions when building the design.

By virtue of its high bearing capacity, steel frame structures are often chosen to build technical facilities, infrastructure, or industrial parks that use this type of structure to ensure safety for the whole project.

2.2 Lightweight

Steel is the lightest material in load-bearing structures made from other materials. Light weight combined with bearing capacity is the exceptional advantage that most investment owners choose for the long-term purpose of the project. Besides, it is also easy to transport, repair, and maintain.

2.3 Sealability and waterproof, termite

Steel materials with waterproof and termite-proof properties will help maintain the building for a long time, minimizing internal losses. Thus, it is especially suitable for construction works with liquid or gas storage tanks.

3. Principle of force transmission of load-bearing steel frame structures

Structural steel frame bearing force consists of 2 main principles related to static and fluctuating loads.

3.1 Fluctuating load

Fluctuating load is the external force acting on the steel frame structure during movement. This load is transmitted to the floor, then to the auxiliary and main beams, from the main beams to the column grid, columns to the foundation system, and finally to the ground.

3.2 Static load

These are the forces applied statically during the erection of the load-bearing steel frame structure. Usually, this structure will lie on top; inside, it is also known as the main gravity of the structure.

For example, the weight of the finishes such as paving, plastering, or the weight of the concrete slab structure is the static weight on the floor structure.

4. 3 common types of load-bearing steel frame structures

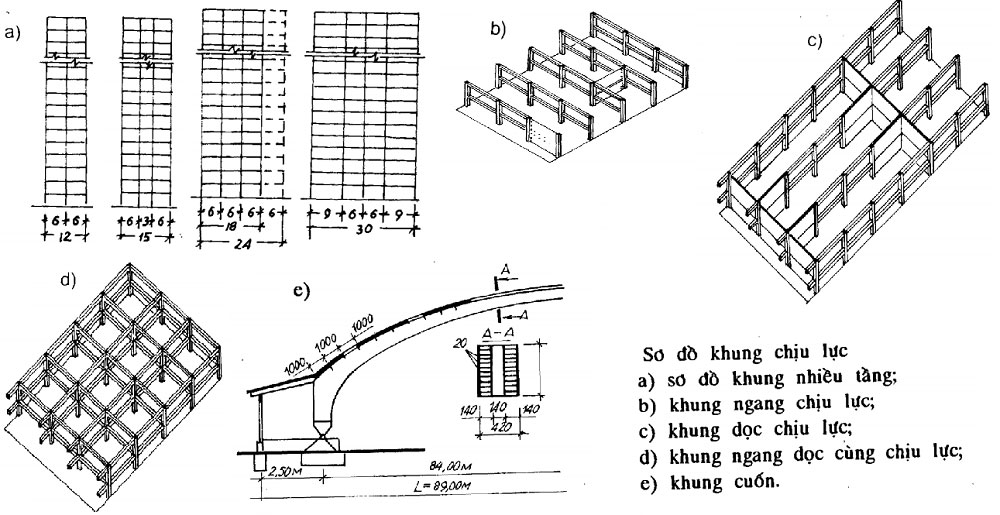

4.1 Load-bearing horizontal frame

This is a type of steel frame whose main beam is positioned above the horizontal frame, so the common point of this type is greater rigidity. This means that this type of flat frame is often applied to industrial factory frames and high-rise buildings, creating corridors or congxon-style loggias.

4.2 Vertical bearing frame

In contrast to the horizontal frame, the load-bearing steel structure's vertical frame has the main beam positioned along the length with the easy configuration of suitable shapes such as balconies, couches, pre fabricated building, etc. This type of frame is commonly found in panel houses when two apertures and a grid of columns are assembled with a size of 6x6m.

Because the vertical frame has less rigidity, the workers use this type of frame to make extra girders or take advantage of the vertical spine of the panel related to the column beam.

4.3 Bearing rolling frame

This is a small branch of the horizontal frame, with the main beam being the curved rod. The advantages of this bearing steel frame are lightweight, high strength, good bearing capacity, and easy construction and repair.

Above are the things you need to know about the bearing steel frame structure that BMB Steel wants to share with your business. Hopefully, the information we share will help your business in the process of developing pre engineered steel building construction for your purposes. Don't hesitate to contact BMB Steel for advice and answers if you have any questions.