Construction of manufacturing industrial factories

- 1. Critical criteria in building a factory

- 2. The process of designing a construction of manufacturing industrial factory

- 3. Substantial requirements in building factories

- 4. Fundamental requirements for construction of manufacturing industrial factory design

- 5. Small-scale production industrial factory models

- 6. Large-scale production industrial factory

Large-scale industrial factories play an exceedingly vital role in the production chain. It is not easy for businesses to build an industrial factory that fully meets the standards and conditions to achieve quality and put it into the production process. Let's learn with BMB Steel the requirements to build a detailed and professional manufacturing industrial factory in the article below.

1. Critical criteria in building a factory

Criteria for industrial building construction is one of the significant factors that assist businesses to evaluate the quality of the construction.

Based on industrial factory construction standards prescribed by Vietnam Construction Code. The fundamental factory building criteria are as follows:

- Standards of safety of the projects: the foundation’s safety and structure’s safety; the capacity needs to meet the production scale of the factory system.

- Standards on the environment and occupational safety: ensuring a working environment for employees against noise and dust, etc; collecting and processing waste; carrying out safety supervision over the entire construction.

- The infrastructure’s connectivity is a substantial factor; the factory system should be designed flexibly to meet a variety of activities in the production process.

- The factory’s design must follow the order of the plan and complete the requirements that were proposed in the drawing.

2. The process of designing a construction of manufacturing industrial factory

The design and construction process of the factory is carried out as follows:

Step 1: Receive and store construction materials

This is a crucial step in the design process. This anticipates the arising expenses materials during the construction process, which causes time loss and disorder in the project sequence. The construction team needs to be careful while receiving and preserving construction materials.

Step 2: Build the factory’s foundation

– Ground leveling: depends on the condition of the ground to decide on ground leveling in the design drawings.

– Locating the main axis: this is an important step to decide on the factory structure because the foundation positions will be based on this main column for construction.

- Digging the fence foundation: it is mandatory to pay attention to the ground’s condition, workers need to be highly technical and meticulous to build a solid foundation.

– Construction of foundation and momentum: a significant step in the entire project’s structure, this absolutely anticipates settlement and foundation deviation.

– Construction of the factory’s floor: conduct an inspection of the wire mesh to ensure that the connection is firm and properly aligned.

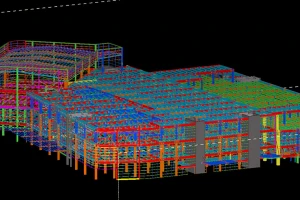

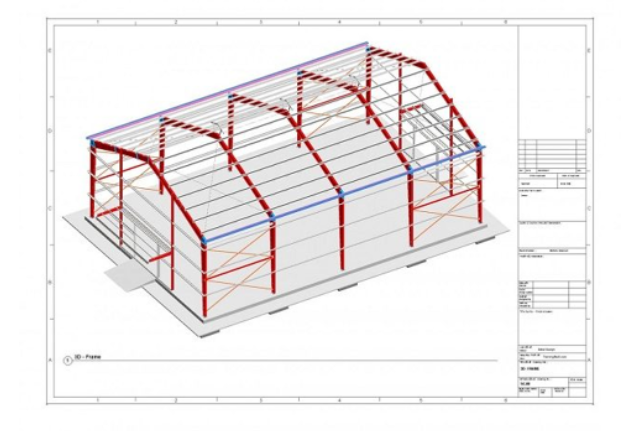

Step 3: Construction of steel frame

Concrete and reinforcement are two materials with good-bearing capacity. The first three steps of this phase are designing, fabricating the structure and completing the erection process at the site.

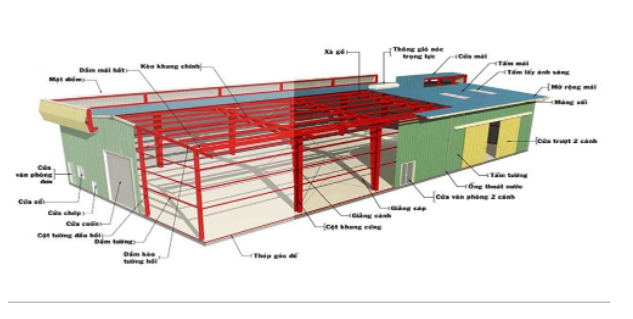

Step 4: Construction of covers for industrial factories

Choosing appropriate factory construction cover will determine the aesthetics and architecture of the steel frame. For large steel frame projects, the factory cover will ensure the reasonable structure and function of the factory.

Step 5: Construction of infrastructure

The technical infrastructure system with design drawings ensures the comfort of the factory’s operation.

Step 6: Construction of technical systems

Technical systems are installed to protect the factory from the environment impacts. They include fire protection systems, communication systems, electrical systems, the technical systems for production, network systems, electrical communication and safety security.

Step 7: Finishing

After the construction process is completed, the necessary equipment will be installed and the space will be designed according to the factory aesthetic standards.

Step 8: Complete cleaning and put into use

The factory, after completing the construction stages, should be conducted a general cleaning before handing it over.

3. Substantial requirements in building factories

Equipment and vehicles in warehouses and pre-engineered steel factories must be installed appropriately: the operation’s scale should be in accordance with the design; the operation process goes smoothly, ensures sanitation and safety, and minimizes pollution. Besides, it should be easy to clean and maintain.

Factory design and working rooms must be suitable to the scale and nature of production technology.

Electricity, technical factors: maintaining power for the whole factory system is essential, so the technical team needs to prioritize this process to operate easily and quickly.

Water system: Adequate water supply, drainage and waste disposal systems are required to avoid polluting the production area and environment, land, air, water, etc

Sanitary facilities: the cleaning area should be reasonably divided for suitable production purposes.

4. Fundamental requirements for construction of manufacturing industrial factory design

Enterprises may not be able to afford to design, construct and build standard factories, so it is essential to pay attention to the primary requirements of industrial factory design:

- Requirements for design drawings on factory design drawings include truss frames, reinforced concrete, factory structure, overall floor plan, and factory architecture. Additionally, the factory must also meet the production requirements, construction standards, occupational safety for workers, etc.

- Technology requirements for impact loads, geological conditions and construction costs should be taken into consideration to choose a suitable design plan and balance investment costs.

5. Small-scale production industrial factory models

In Vietnam, industrial parks tend to choose small-scale factories to minimize initial investment costs. Therefore, businesses have many choices to deciding to build a factory to suit their field and scale of operation:

5.1 Small-scale factory with corrugated iron roof and steel frame

The structure of the factory consists of a steel frame with a corrugated iron roof surrounded.

This is a structural pattern that is easy to disassemble and scale up, so many startups stick with this model.

5.2 Small-scale factory with bright corrugated iron roof

A small-scale factory with a bright corrugated iron roof is a popular project in the tropical region of our country. This factory saves costs on electricity because the design helps to keep the space airy, creating a pleasant and peaceful factory structure.

5.3 Small-scale factory with many windows

The small-scale factory with many windows creates a ventilation system, taking in natural light, and minimizing power consumption for manufacturing enterprises.

5.4 Small-scale factory with narrow walls with corrugated iron roof

The structure of the small-scale factory has narrow walls combined with a corrugated iron roof including: corrugated iron walls, steel pillars and corrugated iron roofs. The factory with solid characteristics is suitable as a warehouse with the heavy loads. Moreover, it meets the standards of environmental impact, suitable for long-term production activities.

5.5 Small-scale factory with steel frame and high wall

The small-scale factory with a steel frame and the high wall is built with a suitable construction time for the production needs of high-temperature products because this factory has high fire resistance compared to other types of factories.

Enterprises will often consider before choosing this factory model because its structure is complicated, so the construction time is long and costly.

The construction of a factory will greatly affect the business’s profit because the production of goods and the operation of machinery all take place inside the factory. Designing small-scale factory drawings will help businesses calculate the cost, area and detailed structure before deciding to build.

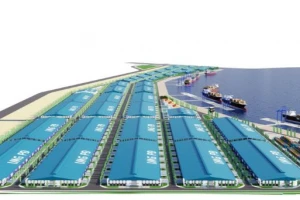

6. Large-scale production industrial factory

The fierce competition in the market requires each enterprise to be proactive in production. In order to increase competitiveness with competitors, the factor of optimizing costs is essential. However, it still has to meet the demand for expansion in the future. Thus, enterprises always have to trade off to build large-scale industrial factories.

Advantages of large-scale factories are considered for businesses:

Saving production costs: Financing for distributed resources management will become easy on a large scale.

Ensure long-term production scale: businesses will not have to upgrade factories many times to meet the needs of goods distribution, saving time to improve the quality of their products.

Easy getting a loan: The construction of large-scale factories helps enterprises to take advantage of other financial businesses. Enterprises easily take advantage of their advantages to have many reasonable loans and create a long-term production scale.

Enterprises in Vietnam always aim to develop and compete with large foreign enterprises, so choosing to build a standard manufacturing industrial factory is a fundamental and essential thing to assist businesses to be home and dry.