Optimal and cost-saving industrial factory construction

For the time being, people are looking for experience and different ways of building and to serve the needs of the market’s preferences and trends. Practically, do you truly and fully comprehend what an industrial factory is? What knowledge and experience is required to build a gorgeous and solid industrial factory? In this article, let’s take a few minutes to learn with BMB Steel for further information.

1. Industrial factory construction methods

The experience in building industrial factories below is inferred from different methods. In order to have perfect construction, you need to have a good understanding of industrial factories and popular construction methods.

There are two primary methods in building industrial factories: the cover structure and the mainframe structure method. Both two methods make industrial factory construction uncomplicated.

- In the mainframe structure: engineers use components such as iron, steel, concrete or composite iron frames to build industrial buildings. Thereby, the main frame was erected with sturdy materials such as iron and steel.

- The pre-engineered steel method is also a solution to build factories. This method is the experience of building industrial factories for a long time. By using reinforced concrete as the main raw material, construction time is considerably minimized and improved.

2. What kind of industrial factory should be built?

This is a question that many people are confused about among different types of factories. Let's find out which one is the best solution for you.

Before making a decision, you need to know these two types of factories: pre-engineered steel factories and reinforced concrete factories. Each type has a different characteristic. Thus, choosing partly depends on individual preferences.

- The pre-engineered steel building is widely used by virtue of its durability and lightweight structure. Moreover, it is a cost-effective solution as the repair process in the future is easier.

- The reinforced concrete factory has a prominent feature of withstanding pressure. Compared to pre-engineered steel, reinforced concrete factories are much more durable. In addition, there are many ways for engineers to design the constructions.

3. The industrial factory construction process

To build an industrial factory, you need to go through the following steps:

Step 1: Design

You need to have a preliminary design of the factory’s scale and structure based on your ideas.

Step 2: Construction of the foundation

This is the step to create the foundation for your house. You should be meticulous and careful in this step because it can play a vital role in the building's quality in the future. You should learn carefully about the ground, the foundation, etc.

Step 3: Steel frame system

Having a strong skeleton is synonymous with having a stronger building. It is highly recommended to use more devices such as lasers, gauges to be more accurate.

Step 4: Roof

The corrugated iron points must overlap each other perpendicularly to the bar frame. You should choose suitable roof types to create an open space for the room.

Step 5: Factory walls

Brick, cement and sand are highly appreciated to ensure sustainability and protect your building from dust and external influences.

Step 6: Carry out infrastructure construction including walkways, stairs, yards, etc.

Step 7: Complete technical systems such as machinery and technical equipment.

Step 8: Finishing the factory is the final stage before putting the factory into practice in perfect condition.

4. Dossier and procedure when building industrial factories

Every industry and field requires relevant procedures such as the real estate procedures, business licenses, etc. For having a construction permit to build an industrial factory, you need to have relevant documentation procedures.

The business registration certificate is indispensable in the construction

The documents you need to prepare are as follows:

- The factory’s completion drawing.

- The construction permit from the local authority.

- The construction contract.

- The financial invoice of the signed construction contract.

- The construction acceptance.

- The certificates of land use rights.

- The business registration certificate.

5. Notes when building industrial factory

When building an industrial factory, you need to pay attention to the following factors:

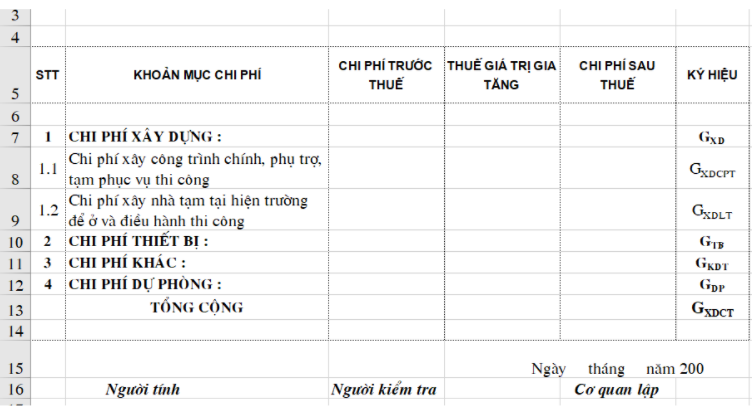

- Based on the detailed calculation of the cost table to proceed with the construction of the factory.

- Pay attention to the terms and conditions of business licenses, documents related to real estate, etc because they are compulsory for any business.

6. Experience in building factories

The following industrial factory construction experiences are meticulously selected and brought to you.

The budget estimate table

Choosing the right land area: this is the key factor because a solid foundation can create a high-quality building in the future. An appropriate layout will assist us in dividing the land reasonably and optimizing the use of the factory.

The factory should be designed in accordance with the business budget and the materials’ nature. After having a preliminary drawing, the enterprise should draw up detailed drawings of parts and equipment in construction. Thus, the project will be designed with detail and accuracy.

Choosing high-quality materials is an imperative step to ensure the durability of the factory. Specifically, we must ensure that the frame is strong and the building materials are closely linked together. Besides, roof, wall, frame are exceedingly critical for a factory, so you have to learn and choose the most reputable ones.