Latest factory construction cost quote

- 1. Construction process, factory construction

- 2. Factory construction costs

- 3. Factors affecting the unit price of factory construction

- 4. The most cost-effective factory construction methods

- 5. Notes to optimize the factory construction cost

- 6. Construction unit price of pre-engineered steel buildings in 2024

- 7. Instructions for estimating factory construction costs

- 8. Frequently asked questions when choosing factory construction

- 8.1 Does a prefabricated steel frame save design time?

- 8.2 Is it possible to save time and costs with prefabricated steel frames?

- 8.3 What type of floor should be combined with the prefabricated steel frame?

- 8.4 For what projects can prefabricated steel frames be used?

- 8.5 Should newly built houses use prefabricated steel frames?

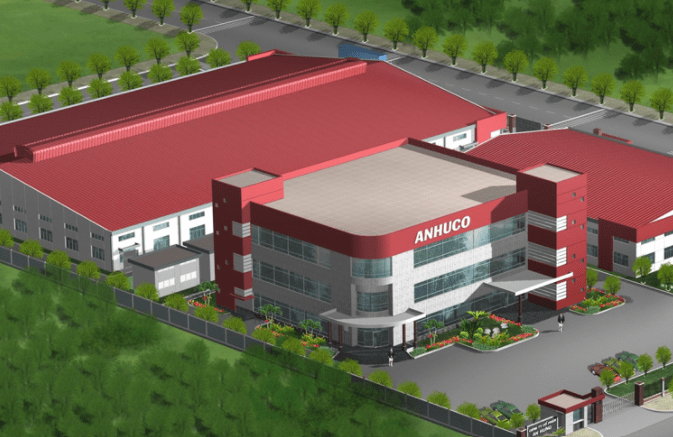

- 9. Some effective 200m2 - 800m2 factory designs today

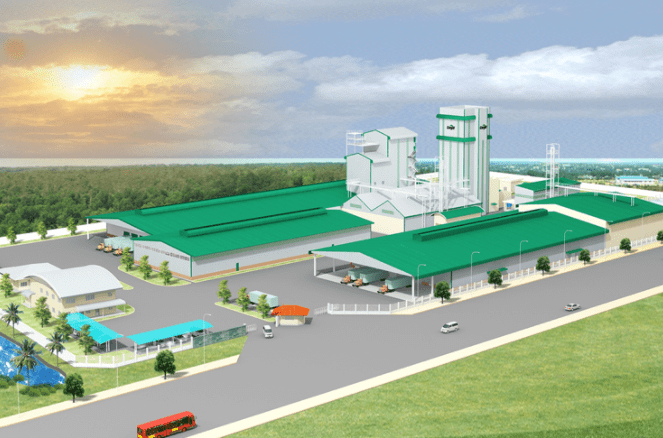

Building and constructing factories at reasonable costs and providing detailed quotes are what businesses are interested in. If you are wondering how much it costs to build a factory? What are the costs of materials and labor to build a factory? Please follow BMB Steel's article below to understand the cost of building and constructing prefabricated factories and then plan your budget accordingly.

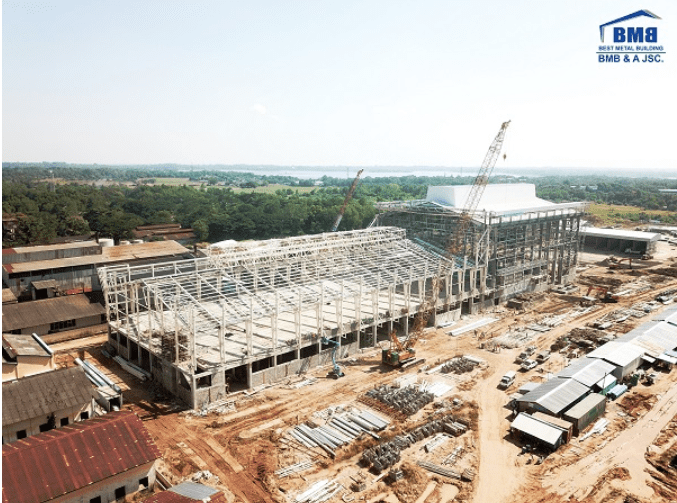

1. Construction process, factory construction

What are the stages of construction and construction of a prefabricated factory:

Design

- Design preliminary drawings, overview,

- Design detailed drawings on software for project approval

Machining

- Import raw material sources

- Check material sources and collage

- Manual welding, automatic welding of materials

- Grinding raw materials, straightening them

- Check and clean components

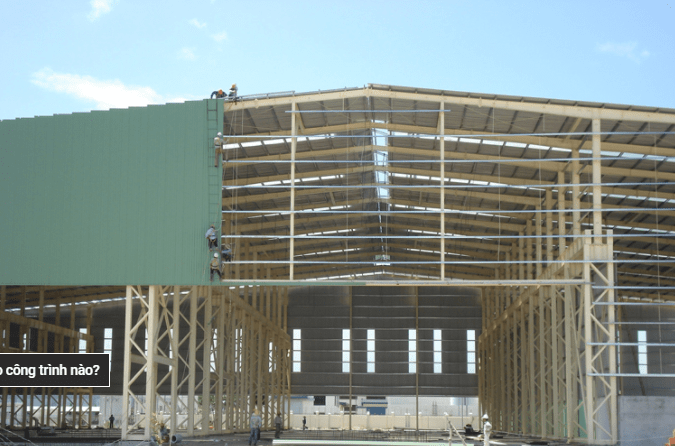

Installation

- Position the anchor bolts

- Install trusses and structures

- Corrugated iron roofing and accessories

- Complete the frame, complete the surrounding structure

Safe acceptance of the project

- Acceptance of the project must check the entire system

- Ensure safety and quality as outlined in drawings

2. Factory construction costs

To build a factory, it is necessary to invest in items including:

- Invest in raw materials

- Invest in human resources

- Costs for machinery and construction plans

- Additional costs for additional services such as security, water, and electricity usage

- Cost of construction permit application procedures, documents...

3. Factors affecting the unit price of factory construction

3.1 Functions of the factory

The first factor that businesses need to pay attention to is the purpose of building the factory and its usage. For example, a factory used as a warehouse will have a different design than a factory used as a company, a restaurant, or a factory used as a construction site. Each different function requires different designs and requires different construction materials. This directly affects the cost of investing in it.

3.2 Factory construction location

Construction location is the next factor affecting factory construction costs. For example, if the location is flat and convenient, it will be easier for the construction worker to move materials, or the processing surface will be easier. The location is rugged, winding, and difficult to transport, requiring additional investment in road paving and infrastructure solutions that take time and money.

3.3 Factory construction scale

Factory construction and construction costs are calculated per unit m2. The larger the scale of the prefabricated steel factory, of course, the higher the construction cost will be. The construction scale should be designed to suit the function and purpose of use.

3.4 Factory model

Designing a simple factory model will only require moderate costs. If you want a sophisticated factory model with many details, the cost will be less.

3.5 Construction materials

Construction materials need to have quality sources. Do not choose cheap materials as this will cause the quality of the project to decline. Materials are an important factor to invest in for a quality factory project.

3.6 Factory construction time

Construction time greatly affects the cost of factory construction. Each year, under the influence of the market economy, raw material prices change, increasing and decreasing differently. Some years, the price of prefabricated steel is high, making it difficult for businesses to invest in construction, but some years it fluctuates lower. Besides, choose the construction time of the year, depending on the weather to determine the cost. The beginning of the year is often a favorable time for construction, saving costs.

3.7 Requirements for the progress of construction works and factory construction

Factory construction needs to ensure the contract between the two parties regarding construction progress and implementation. Delayed construction progress will cause troublesome costs. Construction progress should be promoted as quickly as possible. Ensure the correct time in the contract.

3.8 Factory construction unit

Depending on each contractor and each construction unit, the factory construction price is also different. The more quality, experienced, and reputable the factory construction unit is, the higher the construction cost will certainly be, worthy of the quality of service they spend. Therefore, choosing a construction unit must be good to have a project that meets the requirements of the desired business unit.

4. The most cost-effective factory construction methods

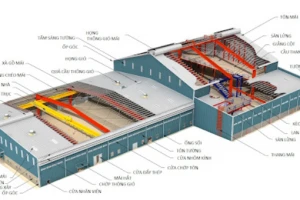

Industrial factories are used to produce and operate production lines of products commonly used for daily life. The frame and the covering structure are two parts that form the factory architecture:

Industrial house frames include Foundations, columns, beams, floors, roofs, beams, windproof frames,...

Covering structure: Roof and walls

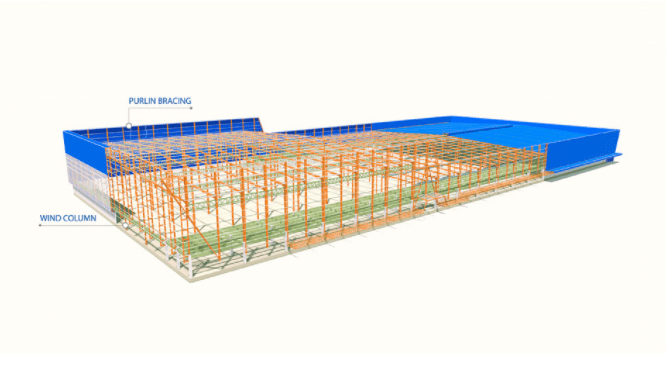

4.1 Main frame structural solutions

There are 3 solutions:

Solution for factory construction costs with reinforced concrete frames

- Certainly, the construction efficiency is high

- Durable in the long term

Solution for the cost of building a factory with a steel frame

- It is possible to create a sturdy frame while still creating a flexible, diverse frame

- Durable material, cost-effective, easy to design

Solution for the cost of building a factory using a composite frame

- The composite frame of steel and concrete doubles its functionality

- The construction is more stable

When choosing the main frame structure design solution, you should rely on the construction needs of the factory to serve the purpose. In addition, the cost of each type of structure will be different. The steel factory frame structure is still more economical than the other two types because the materials require more investment and the design is more sophisticated.

4.2 Covering structure solutions

Another important part of the factory is the covering structure. It will help the factory avoid external influences such as rain, sun, and thunderstorms. Protect assets inside the factory.

The parts constituting the covering structure of the prefabricated factory include:

- Roof

- Wall around

5. Notes to optimize the factory construction cost

5.1 Design phase

- The design must be presented clearly and in detail

- Provide specific design options with a solution if problems arise

- The structure must be reasonable and suitable for the terrain and construction environment to save costs

5.2 Factory construction phase

- Choose a reputable contractor

- Outline the specific construction phases

- Designers, builders, and investors must all understand the design process

- Must comply with the contract agreement

6. Construction unit price of pre-engineered steel buildings in 2024

To know more accurately about the unit price of factory construction, businesses should contact directly construction units, companies specializing in factory construction, and industrial workshops for specific advice.

With diverse construction experience in many small to large factory projects, BMB Steel's multinational scope of operations will offer some popular basic unit prices on the market that we have learned for your reference. and budget estimates. Note that this information is for reference only. For more specific information, businesses should contact the prefabricated industrial factory construction company.

6.1 The pre-engineered steel factory unit price

The price is from 1,500,000 VND/m2 to 3,500,000 VND/m2 depending on the area, the size of the factory, the column truss frame, and the factory floor. This is a price list of prefabricated factories from the general market.

Brief description:

- Reinforced concrete factory floor, epoxy paint

- The height is less than 7.5m

- Combined steel columns and trusses.

- 50mm roof panel, wall panel, aluminum glass door

- Plaster ceiling

For the factory using reinforced concrete columns, pre-engineered steel trusses, and corrugated iron roof, the construction unit price is from 2,000,000 VND/m2 to 2,800,000 VND/m2

Brief description:

- The height is less than 7.5m

- Reinforced concrete column

- Combined steel truss with skylight

- 0.45m corrugated iron roof

- Wall 220 with 4m high and corrugated iron doors

6.2 The unit price of simple factories and warehouses

Area: Under 1500m2; the height is less than 7.5m, steel columns or concrete columns, steel truss, 100mm wall construction, tole wall, tole roof

Without crane: From 1,200,000 VND/m2 – 1,800,000 VND/m2.

With 5 – 10 tons crane: From 1,800,000 VND/m2 – 2,500,000 VND/m2

Brief description of the project:

- The height is less than 7.5m,

- Wall 110 2m high, corrugated door

- 0.45mm one-layer corrugated iron roof

- Steel truss column

- Concrete foundation 15cm thick

6.3 Unit price in prefabricated houses, workshops, and warehouses (without concrete)

Price from: 350,000 VND/m2 – 1400,000/m2, purlin C thickness 1.8mm – 2mm, Iron 5×10, 6×12, Column I100 – I200 or use electric poles to reduce costs and increase product durability. Solid steel for trusses, ciphertext, bolts, screws, tension cable, 4.5zem thick tole roof.

7. Instructions for estimating factory construction costs

Effective cost calculation and management are essential during the implementation of a factory construction project. Ensuring that you understand and manage costs properly will help your project proceed smoothly, ensure financial resources are used to their best advantage, and ensure the quality of the final project meets your needs. target.

7.1 Calculating factory construction costs is necessary

Accordingly, the pre-engineered steel frame is simple to process; the raw materials are only steel, which will save a lot of time for assembly and welding. Unlike reinforced concrete, which uses many mixed materials, it is time-consuming to wait for the concrete to harden.

Calculating factory construction costs has important benefits when you receive construction quotes from contractors or construction units:

- Ensure accuracy: By calculating costs in advance, you have the opportunity to ensure the accuracy of the quotes you receive from contractors. This helps avoid misunderstandings or errors during construction.

- Save time: Helps you choose the contractor that best suits your budget and project requirements.

- Better negotiations: Knowing construction costs helps you negotiate more effectively with contractors. You can discuss cost-cutting or adjusting contract elements to ensure financial efficiency.

- Forecasting financial resources: Calculating costs helps you predict the financial resources needed for the factory construction project. This helps you plan your project finances and ensure that you have enough capital to complete the project.

- Avoid unexpected problems: By calculating costs in advance, you can avoid unwanted surprises during construction. This helps the project go more smoothly and reduces the risk of delays or stoppages.

7.2 How to Calculate Factory Construction Costs

In this section, BMB Steel will go deeper into calculating factory construction costs. This is an important step in the construction project management process and ensures that financial resources are used effectively. Here are the specific steps:

Step 1: Identify basic cost factors

First of all, you need to identify the basic factors that can affect the cost of building a factory. These include:

- Raw Materials: Assess the type and quantity of raw materials needed, along with their value.

- Labor: Determine the number of workers needed and calculate labor costs, including salaries and allowances.

- Machinery and equipment: Assess the need for machinery and equipment during construction and calculate related costs.

- Accessories and incidentals: Includes unforeseen expenses and other incidental costs such as transportation and storage.

Step 2: Calculate the cost of each element

After identifying the cost elements, you will need to calculate the specific costs for each of these elements. Use appropriate formulas to calculate the total cost of materials, labor, machinery and equipment, and incidentals.

Step 3: Summarize and check costs

Once you have calculated the cost of each element, sum them up to get the total cost of building a factory. This will help you know the total amount needed for the project.

Step 4: Compare with online estimates or your estimated plan

If you want to check the accuracy of your calculations, you can compare them with online estimation tools or refer to the estimated plans of construction units. From there, you can review the categories

8. Frequently asked questions when choosing factory construction

8.1 Does a prefabricated steel frame save design time?

This question is asked by many people. Accordingly, the pre-fabricated steel frame is simple to process, the raw material is only steel, so it will save a lot of time, and is easy to assemble and weld. Unlike reinforced concrete, which requires mixing many ingredients, waiting for the concrete to dry and harden takes time.

8.2 Is it possible to save time and costs with prefabricated steel frames?

Prefabricated steel framing can help save time and costs with its simple design process. The shorter the design time, the less costs incurred.

8.3 What type of floor should be combined with the prefabricated steel frame?

For prefabricated steel frame factories, it should be combined with concrete floors to ensure stability. There are desk concrete floors, ultra-light concrete floors, and assembled concrete floors.

8.4 For what projects can prefabricated steel frames be used?

Projects using prefabricated steel frames can be for factories, companies, and offices. Prefabricated steel frames are currently also used in factory design, garage design, supermarket basements,...

8.5 Should newly built houses use prefabricated steel frames?

Today, construction workers increasingly simplify construction methods. Choosing a prefabricated steel frame for a house with a sustainable foundation structure is extremely reasonable. Save investment costs, easy construction, faster time.

9. Some effective 200m2 - 800m2 factory designs today

Hopefully, the above article of BMB Steel has provided you with price information as well as factory construction costs. Contact BMB Steel immediately for specific advice and quotes.