What is metal floor decking? Pros, cons & building guide

- 1. What is metal floor decking?

- 2. Structure of metal floor decking

- 3. Advantages, disadvantages of metal floor decking

- 4. Basic specifications of metal floor decking sheets

- 5. Common types of metal floor decking today

- 6. Applications of metal floor decking in construction

- 7. Installation guide for metal floor decking

- 8. Latest price list for metal floor decking sheets

Metal floor decking is an advanced flooring solution that combines profiled steel decking, steel mesh, and concrete. Thanks to its high load-bearing capacity, reduced structural weight, and faster construction time, this system is increasingly used in pre-engineered buildings, factories, and high-rise projects. If you're looking to understand in detail what is metal floor decking, its components, advantages and disadvantages, technical specifications, construction methods, the latest pricing, the following article from BMB Steel will provide you with a clear and comprehensive overview.

1. What is metal floor decking?

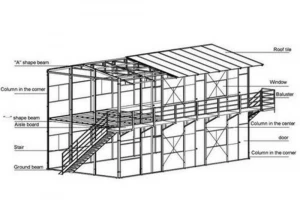

Metal floor decking (also known as decking floor, composite floor) is a type of floor system formed by the combination of concrete, steel mesh, and profiled steel sheets with embossed patterns. These sheets are roll-formed with a wave height ranging from 50-75 mm, commonly have a thickness between 0.75-1.5 mm, and are galvanized on both sides to prevent rust.

During construction, the steel decking serves as a temporary formwork, supporting fresh concrete, rebar, construction workers, etc. The deck sheets are directly installed on the steel beam system using specialized shear studs. As a result, the decking not only replaces traditional formwork but also works together with reinforced concrete to bear loads, thereby accelerating construction progress.

Read more: Common types of steel structures

2. Structure of metal floor decking

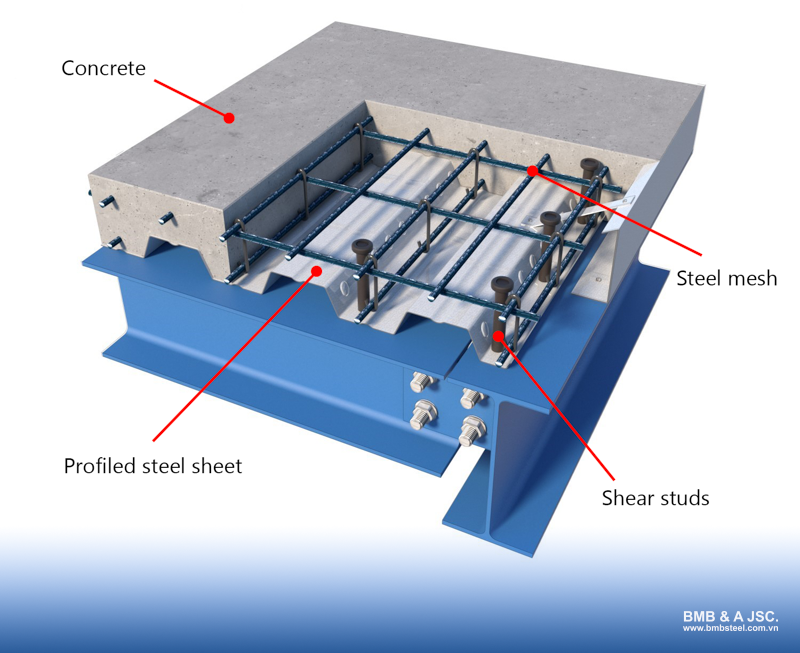

Metal floor decking is composed of a combination of concrete, steel mesh, and profiled steel sheets, forming a composite flooring system with excellent load-bearing capacity. When concrete is poured over the embossed steel surface, the evenly spaced grooves on the sheet enhance the bond between the concrete and steel, creating a strong and stable floor slab. The structure of metal floor decking includes 4 main components:

Profiled steel sheet

This is the bottom layer of the decking system, made from galvanized steel sheets with a rib height ranging from 50-75 mm and a width from 600-1000 mm. The surface of the sheet is often roughened to improve adhesion with the concrete. Using profiled steel sheets helps reduce the structure’s overall weight, shortens construction time by eliminating the need for traditional formwork.

Shear studs

Shear studs provide a firm connection between the decking system and the underlying steel beams. Commonly used stud types are M16 or M19, consisting of 3 parts: the head, body and welding tip.

Steel mesh

The steel mesh functions as tensile reinforcement, enhancing the floor’s strength and helping to prevent shrinkage and cracking of the concrete after hardening. Depending on load requirements, the mesh must be carefully calculated in terms of diameter, spacing, type to ensure the safety and longevity of the structure.

Concrete

This is the top finishing layer, typically using high-strength concrete to ensure long-term load capacity. Two common concrete grades used for metal floor decking are M250 and M300.

Read more: Drawings of pre-engineered steel buildings trending in 2021

3. Advantages, disadvantages of metal floor decking

3.1. Advantages

- Metal floor decking does not require complicated formwork or scaffolding systems, allowing for faster construction progress and the ability to install multiple floors simultaneously.

- It minimizes materials, labor, and construction time, thereby reducing overall building costs.

- Its special structure enables effective connection with steel framing systems, making it ideal for steel frame buildings, prefabricated factories, etc.

- With its lightweight nature, metal decking reduces the load on foundations and structural elements, especially beneficial for multi-story buildings.

- It offers high durability, the galvanized coating prevents corrosion, when combined with high-strength concrete, ensures long service life.

- The galvanized steel surface is bright and visually appealing, allowing for an exposed ceiling finish without the need for plastering or false ceilings.

- It provides flexible design, making it easy to expand or renovate during the building’s lifecycle.

- Good fire resistance, depending on the structure, metal floor decking can withstand fire for 60-120 minutes, meeting fire safety standards.

3.2. Disadvantages

- Since the steel sheets are manufactured according to fixed standards, metal floor decking is not suitable for designs with curved, sloped, or highly customized shapes.

- Installation becomes more difficult in irregularly shaped areas such as triangles, circles, or polygons. This type of floor is best suited for square or rectangular layouts.

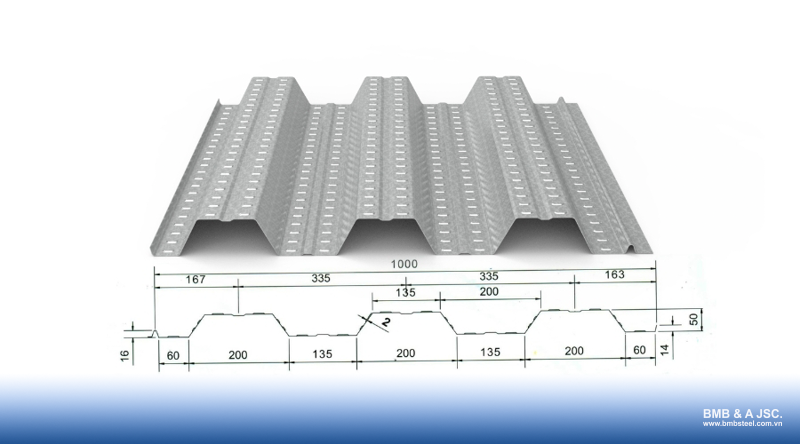

4. Basic specifications of metal floor decking sheets

Depending on the technical requirements and intended use of each project, metal floor decking panels are manufactured in various lengths and thicknesses. However, some common technical specifications include:

- Deck thickness: 0.75–2.5 mm.

- Rib height: H = 50 mm, 71 mm, 75 mm.

- Steel strength grade: G300–G450.

5. Common types of metal floor decking today

Currently, the market offers a variety of metal floor decking types with different rib heights and widths, suitable for various construction types and technical requirements. Some common types include:

- H50W930: decking panel with 50 mm rib height and 930 mm width

- H50W1000: decking panel with 50 mm rib height and 1000 mm width

- H75W600: decking panel with 75 mm rib height and 600 mm width

- H76W914: decking panel with 76 mm rib height and 914 mm width

In addition, there is the speed deck system, which is an integrated solution combining decking sheets and reinforcing mesh into a complete prefabricated system. However, the use of speed deck is still limited due to high costs and the small number of local suppliers.

6. Applications of metal floor decking in construction

Thanks to its outstanding features such as fast installation, lightweight structure, high load-bearing capacity, and good aesthetics, metal floor decking is increasingly used in a wide range of construction projects. It is considered a modern flooring solution, especially well-suited to the trends of industrialized construction and cost optimization.

Typical types of projects that commonly use metal floor decking include: factories, industrial buildings, pre-engineered steel buildings, offices, showrooms, shopping centers, residential houses, apartment buildings, hospitals, schools, etc.

7. Installation guide for metal floor decking

The metal floor decking sheets are delivered to the construction site and positioned correctly on the steel beam system. They are then secured using shear studs, which are welded in place with a specialized stud welding machine.

Next, the construction team installs a layer of welded wire mesh over the deck surface. The mesh typically has a spacing of 150-200mm. Its function is to enhance load-bearing capacity and minimize the risks of cracking and shrinkage in the concrete layer above.

Once the wire mesh is fully in place, concrete is poured directly over the metal deck. The concrete layer is typically 100-150mm thick, though this can vary depending on the load requirements and intended use of the building.

Using galvanized decking sheets eliminates the need for traditional formwork, reduces construction stages, and helps save time and costs. This allows contractors to pour concrete for multiple floors simultaneously without waiting to remove formwork, as is required in conventional floor casting methods.

8. Latest price list for metal floor decking sheets

Metal floor decking sheets come in various sizes and specifications, so the unit price will vary accordingly. Please refer to the price table below for detailed information:

|

Sheet thickness (mm) |

Effective width (mm) |

Weight (Kg/m) |

Unit price (VNĐ) |

|

0.58 |

1000 |

5.45 |

107.000 |

|

0.6 |

5.63 |

111.000 |

|

|

0.7 |

6.65 |

128.000 |

|

|

0.75 |

6.94 |

135.000 |

|

|

0.95 |

8.95 |

165.000 |

|

|

0.58 |

870 |

5.45 |

108.000 |

|

0.6 |

5.63 |

112.000 |

|

|

0.7 |

6.65 |

130.000 |

|

|

0.75 |

6.94 |

139.000 |

|

|

0.95 |

8.95 |

171.000 |

|

|

1.2 |

11.55 |

222.000 |

|

|

1.48 |

14.2 |

272.000 |

|

|

0.58 |

780 |

5.54 |

113.000 |

|

0.7 |

6.65 |

137.000 |

|

|

0.75 |

6.94 |

143.000 |

|

|

0.95 |

8.95 |

172.000 |

|

|

1.15 |

10.88 |

214.000 |

|

|

1.2 |

11.55 |

227.000 |

|

|

1.48 |

14.2 |

278.000 |

We hope this article has helped you better understand what is metal floor decking, its advantages, disadvantages, and why it is widely used in modern construction. Thanks to outstanding benefits such as fast installation, reduced structural weight, and cost savings, metal floor decking has become a preferred choice for many investors and contractors.

However, each project has its requirements regarding load capacity, span length, and construction conditions, therefore, choosing the right type of decking is crucial. Please contact BMB Steel directly for a detailed quotation and expert advice on the most suitable solution for your project.