Reinforced concrete roofs: Structure, types, pros & cons

What are reinforced concrete roofs, and why are they becoming increasingly popular in modern construction? Join BMB Steel to explore in detail their structure, advantages and disadvantages, classification, and construction process in the article below.

1. What are reinforced concrete roofs

Reinforced concrete roofs are made from a combination of concrete and steel reinforcement. In this structure, the concrete bears compression and provides rigidity, while the steel enhances tensile strength, resists bending, and minimizes cracking. Thanks to this strong bond, reinforced concrete roofs offer excellent stability, waterproofing, heat resistance, and exceptional durability. Therefore, they are widely used in residential buildings and large-scale construction projects.

Read more: Top 7 reputable pre-engineered steel building construction companies in Ho Chi Minh City

2. Structure of reinforced concrete roofs

The structure of a reinforced concrete roof consists of the following layers:

- Load-bearing layer: This is the most important part, responsible for carrying the entire load of the roof. It is typically made of monolithic or precast reinforced concrete, with a structure similar to that of a floor slab.

- Slope layer: Positioned above the load-bearing layer, this layer helps rainwater drain quickly, preventing water stagnation and leakage. Common materials include concrete or clay bricks.

- Waterproofing layer: This layer prevents rainwater from seeping through the slab, protecting both the roof structure and the interior space. It is usually made from bitumen membranes, waterproof cement, or waterproof coatings, with a typical thickness of 30–50mm, most commonly around 40mm.

- Finishing layer: The outermost layer protects the waterproofing layer and enhances the building’s aesthetics. It can be finished with tiles, corrugated iron sheets, roofing materials, etc.

3. Advantages and disadvantages of reinforced concrete roofs

Reinforced concrete roofs are increasingly popular in modern construction due to their exceptional durability and sleek appearance. Below are the detailed advantages and disadvantages of this roofing type.

3.1. Advantages of reinforced concrete roofs

- High strength and durability: Reinforced concrete roofs are made from materials with excellent load-bearing and deformation resistance. This ensures long-term stability and minimizes cracking.

- Variety in design and modern aesthetics: Concrete roofs can be designed in various styles to match the owner’s preferences and architectural orientation. This versatility makes them a common choice for modern and high-end buildings.

- Low maintenance cost: Thanks to their solid structure and great waterproofing ability, reinforced concrete roofs require minimal maintenance. When constructed properly with standard waterproofing, they can last for decades without significant damage.

- Good thermal insulation: The thickness of the concrete layer enhances thermal resistance, keeping the indoor space cool. This helps homeowners reduce electricity costs for air conditioning.

- Excellent sound insulation: With a dense and monolithic structure, reinforced concrete roofs effectively block noise, providing a quieter indoor environment compared to metal or tile roofs.

- High corrosion resistance: Reinforced concrete is highly resistant to corrosion and can withstand harsh environmental conditions, making it ideal for coastal areas or humid regions.

Read more: 13+ Modern popular industrial building drawings

3.2. Disadvantages of reinforced concrete roofs

- High initial cost: Compared to metal or tile roofs, reinforced concrete roofs are more expensive due to higher material and labor costs.

- Heavy weight: Concrete roofs are significantly heavier, putting more pressure on the building’s structural frame. Therefore, the foundation and columns must be carefully designed and constructed.

- Complex construction process: Building reinforced concrete roofs requires high technical precision and skilled labor to ensure quality and safety. This makes the construction process longer and more labor-intensive, thus increasing costs.

4. Types of reinforced concrete roofs

Reinforced concrete roofs can be designed and constructed in various forms. To choose the most suitable type, you need to understand the common categories of reinforced concrete roofs below.

4.1. Classification by shape

Flat roofs

This type of roof has a flat surface with little to no slope. Flat roofs are commonly used in residential buildings, offices, warehouses, high-rise structures. They are convenient for arranging rooftop gardens, terraces, solar energy systems, outdoor living spaces.

Sloped roofs

A sloped roof has an inclined surface with a slope of 2-15%, which helps drain rainwater quickly, minimize water stagnation, and reduce the risk of corrosion. This type of roof is often used in factories, workshops, industrial areas.

Read more: Detailed civil pre-engineered steel building drawings

4.2. Classification by construction method

Cast-in-place reinforced concrete roofs

This type is constructed by pouring concrete directly at the construction site, forming a monolithic structure. Cast-in-place roofs offer high load-bearing capacity, fewer joints, and a more aesthetic appearance.

Precast reinforced concrete roofs

This type of roof is made from precast concrete slabs produced in factories and then transported to the construction site for assembly. Its main advantage is faster construction time, making it suitable for large-scale projects or those requiring rapid progress.

Read more: Common types of steel structures

4.3. Classification by load-bearing structure

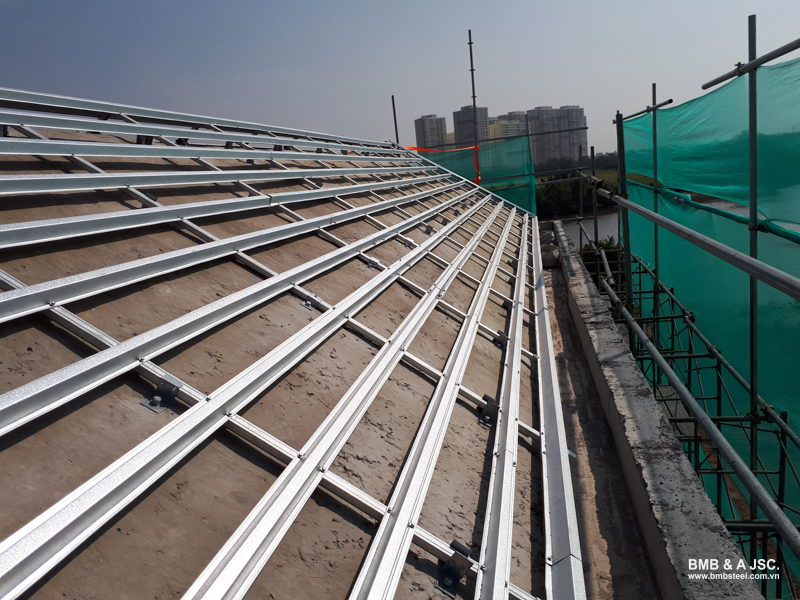

Reinforced concrete roofs with trusses

This roof type uses steel or wooden trusses as the main load-bearing structure, while the reinforced concrete layer serves as the surface slab. The combination of the truss’s flexibility and reinforced concrete’s rigidity makes it ideal for structures requiring high load-bearing performance.

Read more: The steel structure fabrication process meets the most detailed standards

Reinforced concrete roofs without trusses

In this design, the reinforced concrete itself entirely performs the load-bearing function without any supporting truss system. The monolithic structure helps reduce material costs and simplifies the construction process. This type is often used in projects that require a clean, minimalist, and modern aesthetic.

5. Applications of reinforced concrete roofs

- Residential buildings: Reinforced concrete roofs are the top choice for townhouses, villas, etc. This type of roof not only ensures a solid structural foundation for the house but can also be utilized as a terrace, rooftop garden, or outdoor play area.

- Industrial buildings: For factories, warehouses, and production facilities, reinforced concrete roofs are often preferred due to their excellent waterproofing and fire resistance. These properties help protect goods and machinery safely.

- Public buildings: Schools, hospitals, factories, administrative centers, etc., commonly use reinforced concrete roofs for their high durability and ability to cover large areas. The roof can be designed with uniform dimensions, providing a spacious, safe, and sustainable environment for users.

6. Notes when constructing reinforced concrete roofs

Constructing a reinforced concrete roof requires high precision to ensure the project’s quality and longevity. Below are important considerations you should keep in mind during construction:

- Choose suitable materials: The quality of materials is the key factor determining the roof’s durability. The concrete must have good plasticity, waterproofing, and load-bearing capacity, while the reinforcing steel should meet standard strength requirements to enhance tensile and bending resistance, helping the roof withstand harsh weather conditions.

- Accurate structural calculation: Before construction, it is essential to calculate the roof load and structure precisely to ensure safety. This includes both dead loads (the roof’s own weight) and live loads (wind, rain, snow, rooftop equipment, etc.). The roof thickness, dimensions of beams, columns, and foundations, must be properly determined to ensure sufficient load-bearing capacity.

- Follow proper construction techniques: The construction process of reinforced concrete roofs must strictly adhere to technical standards and procedures. Steel reinforcement must be placed correctly, ensuring proper anchorage and spacing according to the design drawings. Concrete should be mixed in the right proportions, poured continuously, and properly cured. In addition, special attention should be given to waterproofing and joint treatment, as these are critical factors that determine the roof’s quality and durability.

- Perform regular maintenance: After completion, periodic maintenance is essential. The roof should be inspected and cleaned regularly to remove debris that could cause water stagnation. Small cracks should be monitored, and the waterproofing layer should be renewed when necessary to prevent water penetration into the structure. Consistent maintenance helps extend the lifespan of reinforced concrete roofs.

When designed and constructed properly, reinforced concrete roofs help optimize maintenance costs, extend the building’s lifespan, and create a safe, solid living space. If you are looking for a durable and modern roofing solution, reinforced concrete roofs are definitely worth considering.

We hope this article has helped you better understand what reinforced concrete roofs are and their practical applications in construction. For detailed consultation on the design and construction of reinforced concrete roofs, please contact BMB Steel to receive the most suitable advice for your project.