4 types of metal roof ventilation and why it matters

Metal roof ventilation plays a crucial role in maintaining your building’s comfort and efficiency. Without proper ventilation, trapped heat and moisture can damage your roof, reduce energy efficiency, and shorten its lifespan. In this article, BMB Steel will help you explore why metal roof ventilation is essential, the risks of poor airflow, and the 4 main ventilation types that help your roofing system perform optimally.

1. Why metal roof ventilation is necessary

Metal roofs are highly valued for their strength, longevity, and excellent energy efficiency. However, without proper ventilation, even the most durable metal roofing systems can experience serious problems over time. When heat and moisture become trapped in the attic, they can cause mold growth, wood rot, and force your cooling system to work harder during hot seasons.

A well-designed metal roof ventilation system allows fresh air to enter while letting warm, moist air escape, protects the building’s structure, and improves indoor air quality. Moreover, effective ventilation ensures that metal roofs perform optimally for decades.

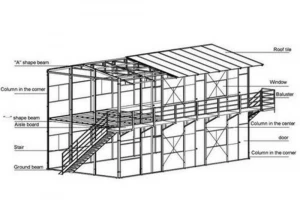

Read more: Common types of steel structures

2. Risks of poor metal roof ventilation

A metal roof without proper ventilation can lead to a variety of serious issues:

- Heat buildup: When heat becomes trapped beneath the roof, indoor temperatures rise, making living spaces uncomfortably warm and increasing dependence on air conditioning.

- Moisture problems: Poor airflow allows humidity to accumulate in the attic, creating ideal conditions for mold and mildew growth, potentially causing structural damage.

- Reduced lifespan: Excessive heat and moisture accelerate the wear and corrosion of metal roofing materials, significantly reducing their durability and requiring early replacement.

- Ice dams: In colder regions, insufficient ventilation can lead to uneven roof temperatures, causing ice dams to form, which can trap water, damage the roof surface, and result in leaks inside the building.

3. 4 types of metal roof ventilation

Choosing the right ventilation method depends on your roof’s design and structure. Most effective systems combine both intake and exhaust vents to maintain continuous airflow throughout the attic. Below are 4 common types of metal roof ventilation systems:

3.1. Ridge vents

Ridge vents are among the most efficient ventilation options for metal roofs. Installed along the peak of the roof, they allow warm, moist air to escape from the attic naturally. This continuous exhaust line promotes balanced airflow and works particularly well with standing seam metal roofs.

Read more: Drawings of pre-engineered steel buildings trending in 2021

3.2. Soffit vents

Soffit vents are placed under the roof eaves and serve as intake openings that draw fresh air into the attic. When used together with ridge vents, they create a natural convection cycle, allowing cool air to enter through the soffits while hot air exits through the ridge. This combination helps regulate attic temperature and humidity, which are critical parts of any ventilation system.

3.3. Gable vents

Gable vents are installed on the vertical ends of the roof. They enhance cross-ventilation by allowing air to flow horizontally through the attic. Although not as common as ridge and soffit systems, gable vents are an effective supplement for large attics.

3.4. Mechanical ventilation

In hot or humid climates, natural ventilation alone may not be sufficient. Mechanical ventilation systems, such as attic fan, actively remove hot, stale air and bring in cooler air, even during extreme weather conditions.

4. 6 steps for metal roof ventilation

Proper metal roof ventilation goes beyond simply installing a few vents. It requires a carefully designed system that ensures balanced airflow. Below are 6 steps to achieve effective ventilation:

Step 1: Calculate the ventilation requirements

Start by determining how much ventilation your attic needs. Follow the 1:150 rule, which means providing 1 square foot of ventilation for every 150 square feet of attic space. If a vapor barrier is installed, you can use a 1:300 ratio. Divide the total ventilation area evenly between intake and exhaust vents to maintain balanced air pressure and prevent ineffective airflow.

Step 2: Plan intake and exhaust vent placement

Intake vents should be installed near the eaves, typically as soffit vents, while exhaust vents belong near or at the roof peak, such as ridge vents. For buildings requiring extra ventilation, consider adding gable vents or mechanical fans. The objective is to create a smooth airflow path from the lower to the higher parts of the roof.

Step 3: Choose compatible vent products

Always select ridge vents specifically designed for metal roofs. Ensure soffit vents are appropriately sized to meet the airflow needs of your building. All venting products should comply with building code standards and be compatible with metal roofing materials, which expand and contract with temperature changes.

Step 4: Prepare the roof and attic space

Before installation, clear any insulation, dust, or debris blocking ventilation paths. Inspect the attic for mold, mildew, or water damage before proceeding. Install baffles to maintain airflow through insulation layers. A clean and well-prepared attic ensures smooth and consistent airflow across the system.

Step 5: Install intake and exhaust vents

Begin by installing the intake vents (soffit vents) if they aren’t already in place. Cut the openings carefully and secure vents using corrosion-resistant fasteners. Next, install ridge vents along the roof peak beneath the ridge cap, following the manufacturer’s instructions for proper sealing and alignment.

Step 6: Test and inspect the ventilation system

After installation, test the airflow using a smoke pencil or airflow meter. Check for any signs of condensation, trapped heat, or uneven airflow in the attic. Schedule annual inspections to maintain system performance. Regular maintenance helps prevent long-term damage and extend your metal roof’s lifespan.

Read more: Instructions for reading detailed and optimized factory structure drawings

5. Common mistakes to avoid in metal roof ventilation

Improper metal roof ventilation can lead to costly repairs, reduced energy efficiency. Here are common mistakes:

- Blocking vents with insulation: One of the most frequent issues is covering intake vents with attic insulation. Always use baffles to keep air channels open.

- Relying on exhaust only: Exhaust vents alone are not effective without a proper intake system. A balanced system with both intake and exhaust vents is essential for optimal performance.

- Over-ventilating: More ventilation doesn’t always mean better results. Excessive airflow can cause negative pressure, drawing in unwanted moisture and increasing energy consumption.

- Using incompatible materials: Not all vents are suitable for metal roofs. Choose vent products specifically designed for metal roofing and ensure they match your roof’s slope, pitch.

6. How to maintain a metal roof ventilation system

Regular maintenance plays a crucial role in ensuring your metal roof ventilation system continues to operate efficiently. Here are a few key methods to follow:

- Inspect for blocked vents: Periodically check all soffit vents, ridge vents, and gable vents to make sure they aren’t obstructed by insulation, dust, or debris.

- Check for leaks: Examine the flashing and sealant around ridge vents and other openings for any signs of cracks, corrosion, or water intrusion.

- Clean vents annually: Over time, dirt, leaves, and debris can accumulate around vents. Schedule an annual cleaning to keep air passages clear.

Proper metal roof ventilation is essential for keeping your building cool, dry, and energy-efficient. By choosing the right venting system, you can prevent moisture damage, lower cooling costs, and extend the life of your metal roofing. Regular inspections and maintenance will ensure the system continues to work effectively for decades.

If you’re planning to install or upgrade a metal roof ventilation system, consult with experienced professionals like BMB Steel to ensure the best results for your building’s needs.