Integral notes when designing a factory

- 1. Industrial factory’s land subdivision

- 2. The master plan

- 3. Traffic segmentation

- 4. Optimize the land area and enhance the construction density

- 5. Flexibility

- 6. Calculate future scalability

- 7. Ensure the construction phase to complete the solution

- 8. Factory lighting system

- 9. Ventilation direction

- 10. Air conditioning

Designing factories with high-quality standards will help owners utilize most of the land's functions, save costs, and create a safe working environment for employees, which allows them to work efficiently. BMB Steel will provide you with sufficient notes when designing and constructing warehouses and pre-engineered factories in the article below.

1. Industrial factory’s land subdivision

To make effective use of the land area, the owner needs to divide the factory into a group of small factories clearly. Besides, the equipment should be separated by specific functions. A conventional construction ground will be divided into the following zones:

- The area in front of the factory: This is usually the entrance area, the administrative area, or the rooms to welcome guests and display products. Depending on the scale of the industrial park, these areas can be arranged in the same place or divided into different areas.

- Production area: This is where to allocate and arrange introductory and sub-production workshops and production lines.

- Production auxiliary area: This place assists for the production line, where workshops, energy, power or transformer stations, operators, pumping stations, and technical networks are located

- Warehouse and transportation area: This area is used to store all kinds of materials, in charge of exporting and selling finished products of the factory, serving the storage of transport equipment.

2. The master plan

To save time, increase labor capacity, and work efficiency, it is vital to design the premises to shorten transportation time and facilitate production. Therefore, the subdivisions at the factory are divided into zones as follows:

- The area with the highest volume of transportation is where raw materials and materials are received and where goods are exported.

- Medium volume shipping area: This is in charge of transporting back and forth between the factory.

- Low shipping volume area: This is the area to transport and receive the last steps of the goods flow.

3. Traffic segmentation

For easier circulation, controlling subdivisions, and organizing goods flow, laborers should be divided into specific areas. Thus, the density of workers will be harmonious with the organized factories. The workforce should be organized as follows:

- Goods flow the flow of goods and materials to transport goods and import necessary production materials for the factory.

- The flow of people: Most workers move to the factory to work or move from one factory to another.

The goods and labor flow must be arranged neatly to limit congestion. Therefore, it will be convenient in the process of moving and transporting goods. In the event of two flows crossing each other, it is indispensable to arrange more overpasses or routes to make it as convenient as possible.

4. Optimize the land area and enhance the construction density

To optimize land use, builders must have a general factory design and optimal plans to help owners save the land and avoid incurred expenses. Here are some options that are widely used in designing factories:

- Consolidation into blocks: If the departments, administrative areas, and workshops share the same sanitary, climatic, and construction parameters, they can be grouped together in one area. Thus, this building will reduce construction categories and costs for electricity, water and shorten the transportation network or technical pipelines.

- Architectural design: Building factories for production use, factories, and warehouses should have simple architecture such as boxes, rectangles, etc., because ordinary floors reduce construction costs and save the land.

- Increase the number of floors: Increasing the number of floors is an effective solution to expand the usable space and increase construction density. However, the number of floors has to comply with state regulations.

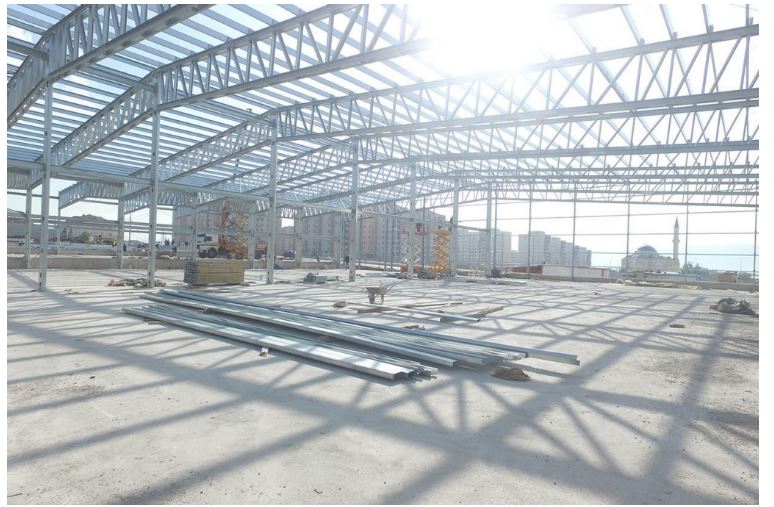

5. Flexibility

Factory design needs to ensure the flexibility to keep the building from being outdated over time and improvising appropriately when there is a new change in products. The flexibility of a factory can be improved by:

- Build a wide floor and ground, avoid trusses and columns so as not to be obstructed or entangled in the working process. Besides, it can be arranged and rebuilt without difficulty in the future.

- There are no significant or fixed obstacles such as reinforced concrete walls or solid partitions above the floor.

- Provide an overhead power system to be close to equipment in upper places.

- The floor is designed to withstand the weight of heavier machinery. If there is a change in machinery, it can still withstand the force.

- Carry out the installation and do not fix the machines to ensure they can still move flexibly if there is a need in the future.

6. Calculate future scalability

In case you want to expand your building in the future, it is crucial to have solid and high-quality designs in terms of load-bearing capacity, a solid foundation, and flexible designs to make your future expansion easier. Depending on your need when expanding, the building will be extended in suitable length or width. If you decide to extend the length and width, you can quickly broaden these building shapes: F, E, H, L, U, T.

7. Ensure the construction phase to complete the solution

At the factory site, it must be divided into steps and periods to be built in accordance with the construction process of the work and the planning.

Therefore, when making design drawings, architects need to have an overview of the organization and the specific operation of the factory. Spaces and architecture should be planned before, during, after using, or when you intend to expand your factories.

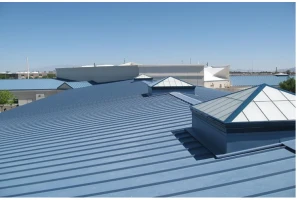

8. Factory lighting system

Light is the factor that plays a vital role in creating a comfortable working environment for employees. It helps increase labor productivity, reduce the risk of occupational accidents, and increase employee satisfaction.

Lighting has many advantages such as:

- Output increases, costs decrease

- Product quality is improved

- Improve employees’ morale

9. Ventilation direction

Ventilation is the factor that makes the environment fresher, replaces toxic air with fresh air, removes impurities in the air, unpleasant odors, and increases the temperature and humidity. Therefore, it is imperative to firmly design the floor walls to arrange ceiling fans or vents for working spaces.

10. Air conditioning

Air conditioners control temperature in the air, humidity, and seasonal cleanliness. They are essential to have a cool working environment, reduce work pressure. Incredibly, they preserve raw materials and finished products effectively.

The article above is some important notes for businesses when designing factories. BMB Steel hopes that you have been provided with more information and suitable equipment for the design drawings of the factory and pre-engineered steel factory.