Fundamental principles when designing industrial factories

Along with the development of the modern economy, the requirements for industrial factories are gradually being enhanced. Therefore, information related to factory design and construction has been particularly concerned about recently. In this article, BMB Steel will give you some fundamental notes when designing an industrial factory.

1. The master plan arrangement

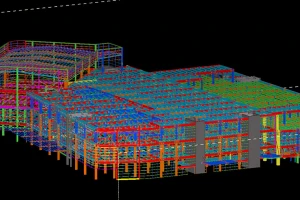

One of the most significant factors when designing industrial factories is the master plan. What exactly is the master plan? It can be simply understood as the projections of the building on the construction site.

The master plan of a building illustrates the whole view of the building such as the system of rooms, roads, trees, etc. Furthermore, the master plan also contains the rooms in the planning projects.

Therefore, when designing, it is mandatory for engineers to pay special attention to the master plan. Specifically, the engineers need to have a structure and arrangement plan to arrange the space of the building reasonably. Thus, it is compulsory to have a master plan.

This is considered one of the most critical steps in industrial factory design. Since you have a good master plan, the building will be most effective when it comes into operation.

2. Arrange and distribution areas for convenient traffic.

The land used for the construction of industrial factories must ensure geological factors, traffic problems, etc. These factors should be carefully taken into account. The chosen land should be adjacent to or at least near main traffic routes.

Not only does this support the construction process but also has important implications for the future operations of the business. In fact, all industrial areas are located close to national highways to transport goods conveniently. Therefore, you need to pay attention to the allocation of convenient traffic areas for industrial factories.

In addition, the traffic system inside the building should be taken into consideration. Specifically, engineers need to take notice of reasonable and scientific traffic flow to support the subsequent operation.

3. Factory’s function

When designing an industrial factory, you need to focus on the function of the investment enterprise as well as the use function of the building, specifically:

- The area in front of the factory: This is the area that usually includes administrative buildings, entrance gates, security rooms, etc.

- Factory production area: This is where production activities take place, including workshops, etc.

- The production support area: It includes workshops that support the production process and production lines.

- Finally, the warehouse area and transport units of industrial factories.

4. Scalability

In addition, when designing a project, you also need to carefully consider the ability to expand the factory systems in the future. In the contemporary world, the ability to expand businesses is exceedingly potential. Thus, the requirements for project expansion are also increasing.

Hence, you need to have a land reserve right from the early stage of industrial factory design. This will help you avoid dismantling or demolishing some areas that are costly and unnecessarily wasteful.

5. Light

Lighting is a significant factor in all industrial buildings. Thus, in the design process, special attention should be paid to this system. Specifically, lighting not only helps increase productivity and work efficiency, but it also helps reduce occupational accidents. Therefore, when designing and constructing projects, you need to take notice of this issue.

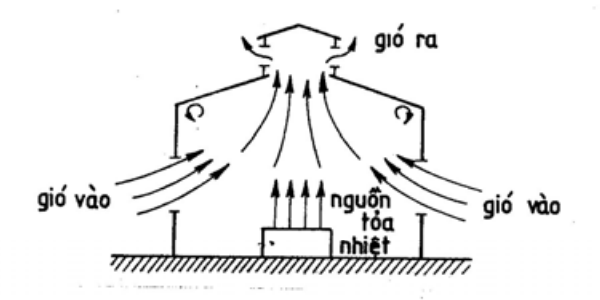

6. Ventilation

In addition to the light, the ventilation system in the factory building is also a substantial factor. Ventilation has the function of purifying the air in the factory. Besides, it helps employees feel comfortable at work and increase their working productivity. Here are some methods of installing ventilation systems in industrial buildings:

- First, the natural ventilation system is the window system or the roof’s fan.

- In some factories, an exhaust fan system is used to keep the air fresher.

7. Segmentation by the level of human resource

One other principle in industrial factory design is to distribute working areas according to the level of human resources

Specifically, in most factories, each area and department will have a different density of workers, so you need to divide it appropriately. Normally, businesses prioritize the division of areas according to the density of employees as follows:

- Areas with a high density of workers.

- Areas with few workers

- Areas with the average number of workers.

8. Segmentation by the level of sanitation, danger, fire and explosion

Safety issues in industrial factories need special attention. Any risk can occur during operation will cause damage to property and even human life. Therefore, in the design process, you need to consider the arrangement of equipment such as fire protection, sanitation to protect laborers.

Specifically, industrial factories should be subdivided into: the first area is non-toxic (safe) areas for workers; the second one is the area with less hazardous to health and working process; the third is the area that has much construction toxic; the last one is the area with a high risk of fire and explosion, which need special attention.

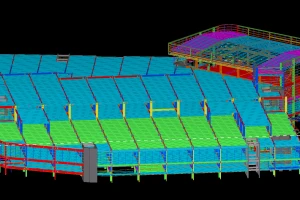

9. Segmentation by volume of factory

In an industrial factory, engineers need to divide into areas with different volumes of transportation. An enterprise with a scientifically designed transportation system between factories will help reduce transportation time and distance.

Specifically, businesses can be divided into the following areas:

- The first is the area with the highest shipping volume: Specifically, this will be the location to receive almost all goods and materials.

- The second is the area with average shipping volume.

- And finally areas with low shipping volume.

The article above is all the information related to the fundamental notes when designing industrial factories. Hopefully, BMB Steel has helped you gain useful knowledge related to industrial factory problems. We hope you soon own a project with the design you want!