Should we build factories by using pre-engineered frame systems?

Building factories is an indispensable thing for many business companies. The factory has the function of storing and classifying goods for business. In addition, it is also a place for the production and designing process, etc. So how to build a good factory? Should you choose to make a pre-engineered steel frame factory? Let's learn more with the following article about BMB Steel.

1. What is a pre-engineered steel frame factory?

A prefabricated (pre-engineered) steel frame factory is a house whose pillar frames are designed using pre-engineered steel. Frames, columns, and trusses are pre-manufactured at the factory and then transported to the construction site for assembly and finishing.

Steel frame workshops can be combined with bricks and concrete to make the surrounding structure. The roof will usually be covered with corrugated sheet metal to protect the entire inside workshop. Factories play a crucial role in business, manufacturing, handicrafts, etc. Thus, they are often built in a large area to produce and store goods sufficiently.

Building a pre-engineered steel frame factory

1.1 Pre-engineered steel frame factory construction process

The process of building a pre-engineered steel frame factory is a complex process, including many specific steps from design to installation. Below is a detailed description of this process:

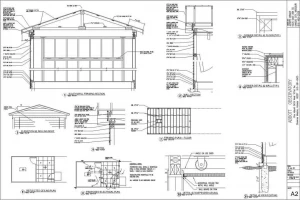

Step 1: Design a pre-engineered steel frame factory

- The process begins with designing a steel frame factory based on the customer's specific requirements and intended use.

- The factory needs to be designed to suit the production process, storage of goods, and labor safety.

- Engineers and architects participate in this process to create detailed designs, including size, shape, door and window locations, insulation systems, and electrical and water systems.

Step 2: Choose materials and place an order

After having the design, the next process is to choose the necessary materials and place an order.

- The main material in steel frame factory construction is prefabricated steel. Prefabricated steel is cut, machined, and welded to form frames, columns, and beams.

- Choosing high-quality and reliable materials is very important to ensure the sustainability and safety of the project.

Step 3: Processing steel frame

- Frames, columns, and beams are processed at the factory with the support of modern machinery and technology.

- Prefabricated steel is cut, drilled, welded, and painted at the factory in preparation for on-site installation.

- Machining must comply with technical standards and ensure accuracy in size and durability of the frame parts.

Step 4: Install the factory

- After the frame parts have been machined, they are transported to the construction site for installation.

- The installation process includes joining the frame sections together, placing stakes, installing insulation systems, and installing doors, windows, and awnings.

- This work needs to be performed by technical and experienced people to ensure the safety and accuracy of the project.

1.2 Characteristics of steel frame factories in construction

- Lightness and strength: Prefabricated steel is light in weight but highly durable, helping to reduce the load on the ground and save infrastructure costs.

- Reusability: Prefabricated steel has high reusability, helping to protect the environment and save resources.

- Save time: Prefabricated steel processing and installation is faster than traditional construction, helping to put the project into operation sooner.

- Design flexibility: Prefabricated steel allows for designs of diverse shapes and sizes, customized to customer needs.

- Durability and safety: Using prefabricated steel ensures sustainability and safety for the project in the long term.

2. Advantages of prefabricated steel frame factories

Building a steel frame factory is a suitable and important choice in production and business activities. This not only helps create good conditions for organizing and operating production processes but also brings many other benefits to businesses. Below, BMB Steel will review the main reasons why building a steel frame factory is a choice worth considering:

What are the benefits of pre-engineered buildings?

2.1 Spacious, large capacity

The steel frame factory has an airy design, facilitating effective storage of goods and machinery. This helps optimize space and increase capacity, suitable for the business's production and business processes.

2.2 Save construction time

The prefabricated steel frame was pre-produced at the factory and then quickly installed at the construction site. This helps reduce construction time compared to traditional methods, allowing businesses to quickly put the factory into production operations.

2.3 High load capacity

Prefabricated steel frames are designed to withstand high loads, helping to ensure safety for the production and storage of goods.

2.4 Easy customization and expansion

Steel frame factories are highly flexible, allowing customization according to the specific needs of the business. If expansion or changes are needed, implementation will be simpler and less expensive.

2.5 Cost-effective investment

Building a prefabricated steel frame factory usually requires less capital than traditional construction methods. All production processes are performed at the factory, helping to save costs and construction time.

2.6 Sustainable production and environmental protection

Steel frame factories often have airy designs, taking advantage of natural light and good insulation systems, helping to save energy and reduce power consumption. This contributes to a sustainable production model and environmental protection.

2.7 Durable and long-lasting

Using prefabricated steel and other high-quality materials creates steel-frame factory buildings that can withstand harsh weather elements and have a long lifespan. This helps businesses save on maintenance and repair costs in the future.

2.8 Save time and maintenance costs

Steel frame factories often require less maintenance and repair work than other types of factories, saving time and costs in the long term.

2.9 Reliable choice

Using high-quality steel and construction materials, businesses can trust in the durability and safety of steel frame factories during production and business activities.

3. Construction cost of pre-engineered steel frame factory

The price of building a project is always something we are all concerned about. Especially when investing in a factory, businesses need to measure and calculate investment costs so that they are reasonable and minimize the costs incurred so as not to cause costs to the business.

To invest in building pre-engineered steel house frames, it is necessary to consider factors such as the investor's requirements regarding architecture and type of materials. Next, you must consider factors such as how long it takes to complete, especially considering which contractor to cooperate with to get a reasonable price.

Factors affecting the cost of building a steel frame factory:

- Area: The area of the factory is a factor that determines the construction price. Larger factories often require more materials and effort, leading to higher costs.

- Geographic location: The location of the project can affect the construction price by affecting the cost of transporting materials and labor. Areas with good infrastructure and easy access often have lower prices.

- Design: Complex and custom designs require more detailed design work and advanced technology, which can increase costs. On the contrary, simple design and use of standard factory templates can reduce costs.

- Material and quality: The choice of material, especially the type of steel, has a great influence on the construction price. Using high quality steel can ensure durability and safety, but also costs more than regular steel.

- Construction time: Projects that need to be completed in a short time often require more labor and resources, leading to increased costs.

- Geological factors: Geological conditions such as soil type, soil strength, and ground stiffness can impact foundation structure and require special work, which can increase costs.

- Electrical and water equipment and systems: Using high-end or complex electrical and water equipment and systems can increase construction costs.

- Safety and regulatory factors: Compliance with safety and environmental regulations may require the use of special materials and equipment, increasing costs.

- Labor market: Labor scarcity and local labor prices can affect construction prices.

- Reusability: Using reusable or reusable materials can reduce construction costs.

Currently, the market has many construction companies to build pre-engineered steel frame factories that you can choose from. However, to find a suitable one, you need to consider it carefully. Many places do not guarantee the price initially, which causes the construction process and the investor to incur unexpected costs.

In detail, you can refer to the price list of BMB steel. BMB Steel Company will publicly clearly provide the prices an owner needs to pay when building a pre-engineered steel factory to explicitly ensure the cooperation process.

4. Should a pre-engineered steel frame factory be built?

The question from the beginning is whether to build a pre-engineered steel factory or not. With the advantages and benefits that pre-engineered frame factories bring, as we mentioned above indeed, building steel frame factories will be the optimal solution with cost-effectiveness for businesses and investors.

At present, the pre-engineered factory is the most profitable, stable, long-term economical solution for you. Therefore, if there is a need to build a factory for stable business purposes, this is a sagacious choice.

5. BMB Steel - A pre-engineered steel building construction company

If you have not chosen a good construction company for your projects, you can refer to BMB Steel - a design and construction company of the pre-engineered steel factory. We are always committed to bringing products and works that ensure quality, and prestige and bring the most sustainable value.

When cooperating with BMB Steel, you will be consulted on the most optimal solution for each project, helping to achieve high benefits. Don't hesitate to contact BMB Steel immediately to start with your dream projects.