7+ industrial factory construction experience

- 1. Land subdivision in industrial factory

- 2. Design suitable factory for each production goals

- 3. Ensure the factory foundation’s solidity

- 4. Ensure frame’s solidity

- 5. Construct walls in harmony with each other

- 6. Construction of the roof of the factory

- 7. Principles of infrastructure when building

- 8. Predicting the factory expansion ability

Building an industrial factory requires meticulosity, knowledge and skill of facing problems. It is particularly obligatory that designers and workers have to have experience in construction. Understanding that, in this article, BMB Steel will provide you with detailed information about the experience of building industrial factories.

1. Land subdivision in industrial factory

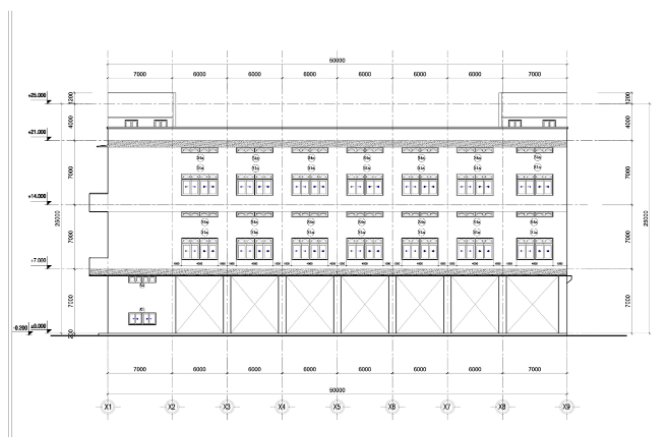

It can be clearly seen that the working construction layout is exceedingly critical. Exceptionally, a suitable and optimal layout is the key factor that contributes to the total quality of factories or production areas.

If the areas of the factory are arranged appropriately, not only does it help the workers move easily but also the product transportation becomes convenient considerably. Besides, proper layout arrangement also helps factory owners save space and maximize the use of functions.

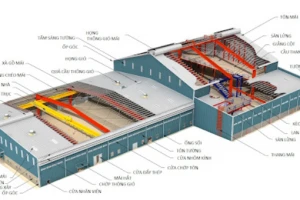

Normally, businesses allocate the layout according to the function of each area such as: Area for production activities, area for supporting production activities, area in front of industrial factory, warehouse area, transportation and commuting area.

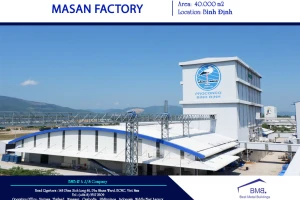

2. Design suitable factory for each production goals

In factory construction, the factory design process is remarkably crucial. Factory design drawings must be appropriate to the nature and purposes of the enterprise.

On the basis of the specific characteristics of the enterprise such as kind of products, construction investment capital, etc, appropriate materials will be thoughtfully chosen for construction. In general, there are two types of factories: concrete factory and pre-engineered steel factory.

3. Ensure the factory foundation’s solidity

There is a fact that if the enterprise chooses a location with solid ground, the factory will be firmly reinforced. In force majeure cases, contractors as well as engineers must consider the option of reinforcing the foundation.

Therefore, before carrying out the construction, business owners need to choose and consider carefully the land area. Besides, issues such as the quality of the land, the surrounding zones and infrastructure should be taken into account thoroughly.

4. Ensure frame’s solidity

When the foundation is completed, the framing phase will be conducted. This phase requires meticulosity and carefulness because the laborers may be in danger if there are any errors.

As a result, contractors and builders must equip workers with the necessary protective gear. Building the frame is the stage that helps to shape your industrial factory, so the factory frame must be strong and durable.

5. Construct walls in harmony with each other

Wall construction is considered as one of the easiest stages in the process of building up a factory. However, this stage requires a good combination of frame and partition.

In addition, at this stage, there is one thing that should be paid attention to: the door system installation; thus, the builder should have a regular project inspection. If there is a problem, it can be solved quickly.

6. Construction of the roof of the factory

Obviously, the factory’s roof plays a vital role in protecting the factory from rain, wind, and sunlight, etc. Therefore, if the roof construction of the roof is not scrupulous, it will cause leaks when a storm occurs. Moreover, it will endanger the lives of workers in the factory.

Currently, in Vietnam, factories mainly use corrugated iron to install roofs. With the nature of corrugated iron being a reasonable price, many models will help customers have a variety of choices.

7. Principles of infrastructure when building

The principle of infrastructure requires certain industrial factory construction experience. When choosing a construction site, businesses must consider the infrastructure of the area.

Businesses have to consider whether the area's transportation system is favorable for the transportation of factory goods or not. In addition, it is necessary to carefully check the water system in the area, the electricity network etc.

8. Predicting the factory expansion ability

When planning to build an industrial factory, businesses should anticipate future possibilities, especially the ability to expand production scale. Surely, every business wants their factory to be expanded.

When choosing a construction site, it is advisable to consider the surrounding area whether it can be acquired or leased for future production or not. The layout also needs to be deliberated about because we may use it as a workshop, auxiliary works or warehouses in the future.

The constructing, planning and creating factory layout processes require the necessary industrial factory construction experience. The supreme requirement is that there must always be coordination from parties in the construction process. This article has provided you with the fundamental knowledge, you can apply it in a reasonable and correct way to gain the highest quality for your projects.