How to build a large-scale factory with effective optimization?

- 1. Typical features when designing large-scale factories

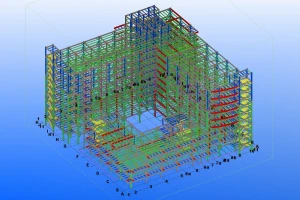

- 2. The structure of the large-scale factory

- 3. Advantages of large-scale factory

- 4. Suitable enterprises for choosing large-scale factories

- 5. Things businesses need to keep in mind when choosing to build a large factory

- 6. Large factory samples

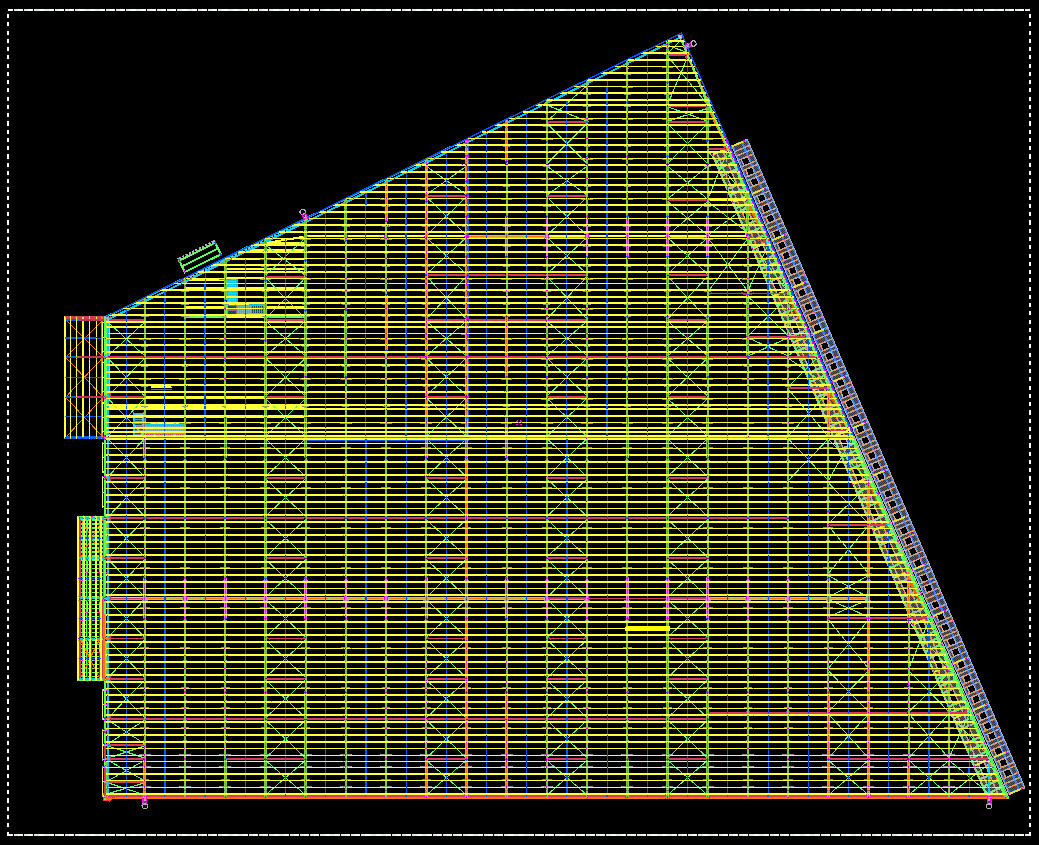

- 7. Large workshop drawings

In March 2022, after nearly 4 years of anticipating and controlling the widespread COVID-19 global pandemic, Vietnam reopened international flights to welcome tourists and promoted restructuring of the production supply chain of enterprises.

It can be clearly seen that the factory is the most crucial factor in the supply chain, deciding the success or failure of the business. Simultaneously with the post-pandemic redevelopment, many businesses choose large-scale factories to optimize operations, increase profits, and promote equity growth.

1. Typical features when designing large-scale factories

Typically, large-scale factories have tens of square meters of the area to store finished products. This is also a place where many laborers work for the production process.

Some notes when designing a large factory include:

- Usually, factory buildings will be built according to the pre-engineered steel factory structure to reduce the load on the foundation.

- The construction will be carried out with pre-designed steel frames (easy to move, highly synchronous, and simple).

- Economic, reasonable costs of raw materials as well as depreciation costs.

- Modern systems help to increase the life of the building.

Outstanding features of the large-scale factory

2. The structure of the large-scale factory

Currently, businesses are aiming for two popular types of factories: multi-story and pre-engineered factories.

However, the latter type is applied more regularly for factories with thousands of square meters of area. Pre-engineered factories assist investment owners in optimizing the construction costs and shortening construction time.

This type of factory is simply understood as the assembly of pre-engineered steel frames at the construction site according to the sketched drawings.

The structure of this process consists of four parts:

- Build the foundation.

- Set up the mainframe system: columns, trusses, beams, etc.

- Secondary structure: wall beams, purlins, bracing systems, etc.

- Install roofing corrugated iron and tole cover.

Industrial factory building

3. Advantages of large-scale factory

Obviously, the construction of a large-capacity factory will take more investment. However, why is it still the first choice of many businesses?

Below, let's find out the benefits of the large-scale factory:

- Maximize production space with a capacity of thousands of people, including the installation of bulky machinery, equipment and assembly lines.

- The cost of building a large-capacity factory is considerably more economical than building small factories with the same total area.

- Increase working efficiency and productivity and save operating costs for businesses.

Designing large-scale factory

4. Suitable enterprises for choosing large-scale factories

Businesses with large scale, high-performance requirements and the need to install massive machinery and equipment as well as extensive human resources are those who should choose large factories.

This will help businesses increase work efficiency, minimize costs and ensure the output quantity of finished products. These are the reasons why this type of factory is an excellent choice for businesses with a large number of customers and a high market share.

The industrial factory design

5. Things businesses need to keep in mind when choosing to build a large factory

Managers and leaders should pay attention to the process of building factories with a large capacity to anticipate problems such as material costs, construction time, or other disadvantages in terms of the longevity or durability of the structure.

In general, businesses need to pay attention to the following categories:

- Carefully consider when choosing the area of construction land. You should select industrial zones, which are far away from residential areas.

- Find a reputable service provider, and avoid businesses entangled in fraudulent, changing materials during construction on their own initiative, which causes risks for businesses.

- Consider and review the pros and cons of multiple drafts to find the best solution.

- Choose materials with high durability to reduce depreciation costs or the life of the facility.

- Continuously monitor and inspect during construction to timely repair and overcome.

The big industry factory building

6. Large factory samples

Sloped roof factory

Flat roof factory

Dome factory

7. Large workshop drawings

In the article above, BMB Steel has provided all the most detailed information about the design and construction of large-scale industrial factories. Hopefully, our information and sharing will give managers and leaders a hint on the optimal choice for their supply chain, helping to maximize chain surplus and gain more long-term benefits in the future.