Industrial factory design standards you need to know

- 1. Standard design of factory ground

- 2. Standard design drawings for industrial factory foundation

- 3. Design standards for factory roofs and roof doors

- 4. Design standards for factory walls and partitions

- 5. Design standards for windows and doors

- 6. Other factory design standards

- 7. TCVN standard on industrial factory design

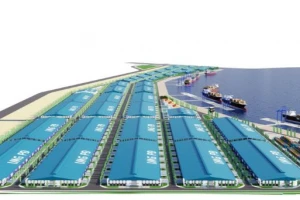

Along with the development of world industry, the requirements for the number of factories also proliferate considerably. Therefore, information related to the design and construction of factories has been particularly involved in this day and age. In this article, BMB Steel will provide detailed information related to the industrial factory design standards.

1. Standard design of factory ground

One of the factors that helps a building have a long operating time is the ground. As this is the place that suffers the most impact when the project is put into use. Therefore, it is exceedingly substantial to comply with the standards for the factory ground. What exactly are those standards? Let's find out with BMB Steel in the following information.

First, the design of the factory ground needs to comply with TCVN 2737: 1995 in terms of load capacity as well as geological conditions at the construction site. This factor plays a vital role in helping you know if the ground is sufficiently solid enough or not to find solutions.

In addition, depending on the future operation purposes of the business owner, the ground will be made of different materials. Specifically, we can divide it into the following types: concrete ground, reinforced ground, concrete ground with impact resistant steel billets, cement tiled ground, wooden plank ground, etc. One of them is the concrete ground, which is widely chosen by many businesses by virtue of its abilities that meet different requirements. For concrete grounds, you need to comply with the following standards:

- The length of each concrete cell must be less than 0.6 m, this helps to better withstand the machines later.

- Between each cell, you need to divide it with bitumen.

- In addition, the lining concrete layer needs to be at least 0.1m thick.

The final standard in the factory construction is that the warehouses and yards (at the viaduct location used for loading and unloading bulk materials) must be flat, the substrate surface must have a hard lining and ensure quick drainage.

2. Standard design drawings for industrial factory foundation

The foundation is the key factor to help the building be solid. Therefore, the requirements for the foundation are more sophisticated. Specifically, to ensure the requirements of geological conditions, the ground must comply with the provisions of TCVN 2737: 1995.

In addition, the foundation is evaluated as high-quality when its design is suitable to the properties, physical and mechanical characteristics of the ground soil as well as the natural conditions in the area. Specifically, the height of the upper part of the foundation must be designed to be lower than the whole building’s foundation.

The differences depend on each type of a column of the specific foundation: for steel columns, it is between 0.2 m and 0.5 m for frame wall columns; for reinforced concrete columns, it is about 0.15m. In addition, you also need to pay attention to some other standards of the foundation such as:

- The height of the steel column base between the corridor and the supporting viaduct must be designed to be 0.2m higher than the ground floor.

- The column foundation between the expansion joints and the factories that plan to expand after the operation should be designed with two adjacent columns.

In addition, you also need to pay attention to the foundation protection. Specifically, the foundation should be made with good heat-resistant materials. Besides, to avoid corrosion after the operation, you need to take certain measures to prevent corrosion.

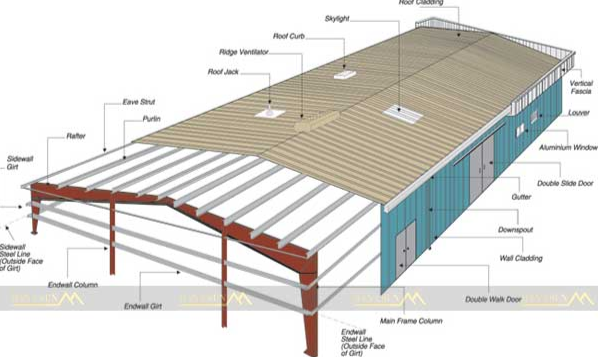

3. Design standards for factory roofs and roof doors

The next thing that we want to mention is the standards related to the design of factory roofs and roof doors. Like other parts of the building, the roof has its own design standards. Specifically, the slope of the roof will depend on the materials:

- For roofs made of asbestos cement, the slope is between 30% and 40%.

- For the corrugated iron roofs, the slope is between 15% and 20%.

- For tiled roofs, the slope is between 50% and 60%.

- In addition, the building has a roof covered with reinforced concrete slabs, the slope of which is only about 5% to 8%.

In terms of the design of drainage system, there are also separate standards for different roofing materials:

- For buildings with multi-span roofs, the drainage system can be designed inside or outside the normal drainage system of the building.

- For factories with single-span roofs, rainwater will flow freely without the drainage system for the roof. However, if the height of the house column is from 5.5m or more, you need to install a downspout system.

Other critical requirement is that the roof door should not be larger than 48m. Thus, it is necessary to install fixed glass for this part. If the building does not have a roof, the one-span or two-span building should be designed to get natural light. If the building has ventilation doors, the building can generate a lot of heat and moisture when it is put into operation.

4. Design standards for factory walls and partitions

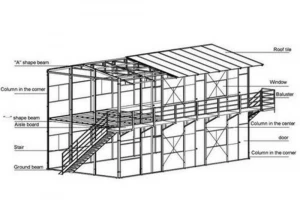

Like the above standards, depending on different industrial projects, there are different types of walls to suit the future operation process. Specifically, there are 3 common types of walls in pre fabricated building or pre engineered steel building: load-bearing walls, self-loading walls and frame walls.

One crucial thing that should be paid attention to in the building’s walls is the design of the wall’s base. Specifically, you need to design a rainproof system by using bitumen or other waterproof material.

In addition, this moisture-proof layer is made of cement mortar with a thickness of about 20cm. You can choose reinforced concrete plastic materials, plywood panels, steel mesh with wooden frames or steel frames to make partitions.

5. Design standards for windows and doors

The next thing you need to pay attention to is the window and door system of the building. Specifically, the standards for these two things include the following requirements:

Aluminum and glass doors of an industrial factory

- The door needs to be opened to the outside, this is the fundamental requirement that you need to know. In addition, the doors’ sizes depend on the type of transportation means when the business operates.

- Next, you need to pay attention to the height of the door. It must be at least 2.4m high above the floor.

- For the window system, it is necessary to design a mechanical opening and closing system.

6. Other factory design standards

In addition to the above standards, we also need to consider some other requirements of industrial factories such as:

- The standards related to the electrical system of the building to ensure safety and high applicability.

- An indispensable factor in industrial factories is the fire protection system. Specifically, when designing, you need to ensure compliance with Decree No. 79/2014/ND-CP issued by the Government.

- And finally, the design standards for systems such as security cameras, lightning protection systems or waste processing systems, etc.

The above information is the fundamental principles you need to know when constructing any industrial factory projects. Applying these standards will make the operation of your business more convenient.

7. TCVN standard on industrial factory design

- TCXD 16-1986 – Artificial lighting in civil works

- TCVN – 4474 1987 – Design standards – Drainage inside works

- TCVN – 4513 – 1988 – Design standards – Water supply inside works

- TCVN 4605 – 1988 – Design standards – Covering structures, thermal engineering

- TCXD 29 – 1991 – Natural lighting in civil works

- TCXD 25 – 1991 – Design standards – Laying of power lines in public works.

- TCXD 27 – 1991 – Design standards – Installation of equipment in homes and public works

- TCVN 5687 – 1992 – Design standards – Installation of equipment in houses and public works

- TCVN 5687 – 1992 – Design standards – Ventilation and air conditioning

- TCVN 5760 - 1993 – Requirements for the installation of fire protection systems

- TCVN 5783 – 2001 – Technical installation requirements – Fire alarm system

- TCVN 6160 – 2005 – Design standards – Fire prevention

- TCXDVN 356 – 2005 – Design standards – Concrete and reinforced concrete structures

- TCXDVN 338 – 2005 – Construction design standard and steel structure VN

- TCVN 2737 – 2006 – Design standards – Impact loads

- TCVN 46 - 2007 - Guidelines for inspection and maintenance of lightning protection systems for construction works

- TCXDVN 394-2007 – Safety section – Design and installation of electrical equipment

- TCVN 4319 – 2012 – Design principles – Houses and public buildings

- TCVN 4514 – 2012 – Design TC –Industrial enterprise, total premises

Above is all information related to design standards for factory construction. Hopefully, the information BMB Steel brings has helped you gain useful knowledge related to industrial factory problems. Wish you soon own a project with the design you want.