Maintenance and repair of pre-engineered steel buildings

Pre-engineered steel buildings are designed to be relatively low-maintenance structures that require minimal upkeep over their lifespan. However, like any building, they may require occasional repairs and maintenance to ensure that they remain in good condition. This writing shall discuss some notes concerning the maintenance and repair of pre-engineered steel buildings.

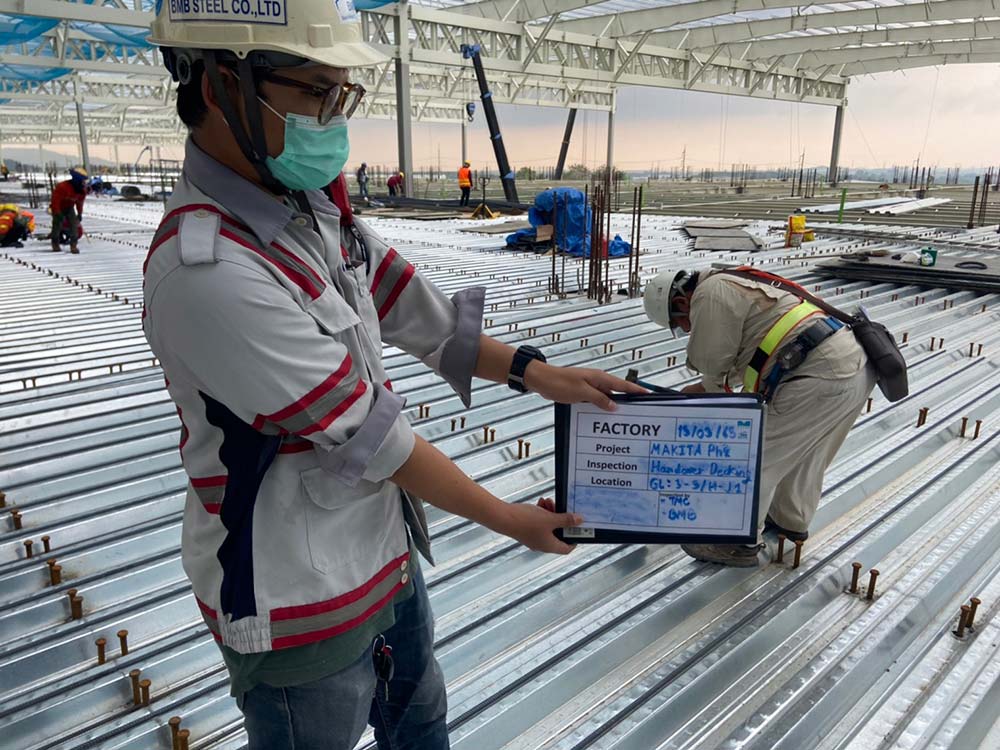

1. An overview of pre-engineered steel building

Pre-engineered steel buildings are structures that are designed, fabricated, and assembled at a factory before being transported to their final location for installation. These buildings are made of steel components that are pre-engineered to fit together, making the construction process faster, easier, and more cost-effective than traditional building methods.

2. Maintenance and repair of pre-engineered steel buildings

It is crucial to maintain and repair pre-engineered steel buildings regularly to ensure that the building performs well and can satisfy the owner's demand. Here are some notes for maintaining and repairing pre-engineered steel buildings:

2.1 Inspect the building regularly

It is important to inspect pre-engineered steel buildings regularly in order to ensure their continued structural integrity and safety. Regular inspections can help to identify any potential issues or areas of concern before they become more serious problems.

When inspecting a pre-engineered steel building, it is important to look for any signs of damage, such as cracks, corrosion, or deformation, and check the foundation, walls, roof, and other structural components for signs of wear and tear, such as rust, corrosion, or loose or missing bolts. In addition, it is important to inspect the building's electrical and mechanical systems, including lighting, heating, ventilation, air conditioning (HVAC), plumbing, and fire protection systems. These systems should be checked for proper function and any signs of damage or wear.

Regular inspections should be conducted by a qualified professional, such as a structural engineer or building inspector, and should be performed at least once a year or more frequently if the building is located in an area with severe weather conditions or other environmental factors that may increase the risk of damage or deterioration.

2.2 Keep the building clean

Dirt and debris can accumulate on the building, leading to corrosion and other damage. Keeping a pre-engineered steel building clean is an important part of maintaining its structural integrity and appearance. This includes regularly removing debris, keeping windows clean, cleaning the HVAC system, sweeping the floor, and so on. These processes help improve the appearance of the building as well as ensure that the building performs well.

2.3 Check the roof

The roof is one of the most critical components of any building, and pre-engineered steel buildings are no exception. Check the roof for leaks, rust, or other damage that could compromise its integrity. This involves looking for signs of damage, such as cracks, punctures, tears, corrosion, rust, or other forms of deterioration; checking for leaks, such as water stains or mold growth; inspecting the flashing; inspecting the roof supports; and so on.

It is important to check the roof of a pre-engineered steel building regularly, at least once a year or more frequently if the building is located in an area with severe weather conditions or other environmental factors that may increase the risk of damage or deterioration.

2.4 Maintain the gutters

Maintaining the gutters in a pre-engineered steel building is important to ensure proper drainage and prevent water damage to the building's foundation, walls, and roof. This includes cleaning gutters to remove debris, leaves, twigs, and dirt; checking for damage like cracks, and holes; ensuring proper slope (straightly toward the downspouts); checking downspouts for any blockages; installing gutter guards; and inspecting after severe weather.

2.5 Repair damage promptly

If any issues are identified during an inspection, address them promptly to prevent further damage. Delaying repairs can lead to more extensive damage and higher repair costs. When repairing damage to a pre-engineered steel building, work with a qualified professional, such as a structural engineer or building contractor, who has experience working with steel buildings. What is more, it is important to use quality materials that are compatible with the building's existing materials and follow strictly manufacturer guidelines. After repairs are completed, monitor the repaired areas for any signs of further damage or issues. Address any concerns promptly to prevent further damage.

2.6 Hire a professional

It is crucial to have professionals process all of the above processes to ensure safety and security. Experts who have a lot of experience working on inspecting, maintaining, and repairing may be:

- Manufacturer: If your pre-engineered steel building is still under warranty, the manufacturer may be able to recommend a qualified service provider.

- Online directories: You can search for providers in your area and read reviews from other customers to help you make an informed decision.

- Local builder's association: Your local builder's association may be able to provide you with consulting or maintaining and repairing services.

Above is some information regarding the process of maintenance and repair of pre-engineered steel buildings. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.