10,000m2 industrial factory drawing and things to know

Building a factory is the most crucial issue of an enterprise. Deciding on the factory's size and how to build the factory is probably the concern of many business owners. Today, let BMB Steel suggest to business owners a type of factory worth referring to - a 10,000m2 industrial factory.

1. Structure of 10,000m2 industrial factory

Industrial factories of 10,000m2 are usually built on pre-engineered steel frames. The fundamental factory will have the following principal structures:

- The foundation: it has the effect of transmitting the entire load of the building to the hard ground below. The foundation of pre-engineered steel buildings can be a tape foundation, pile foundation, single foundation, and raft foundation. Foundation structure of industrial factory 10,000m2: foundation plate (foundation tower), foundation brace (basement), foundation neck height. Pre-engineered steel buildings also use reinforced concrete foundations.

- Foundation bolts: Foundation bolts have the effect of connecting the reinforced concrete foundation with the steel columns of the main frame. Foundation bolts used in constructing large industrial factories are bolts with a diameter of M22 or more.

- Steel columns for factories: Column systems in pre-engineered factories or prefabricated buildings are usually H-shaped and made of steel. In addition, some workshops will use round steel columns.

- Factory steel beams: The beam system is only available in multi-storey factories or workshops with cranes. The most commonly used beams are "I" beams.

- Steel trusses: Steel trusses are used a lot in industrial factory construction projects that need 30-50m. The truss makes of steel beams of variable cross-section or truss form, which is responsible for supporting the purlin system.

- Purlins: Purlins are usually in C, Z, or U shape. The length and height of purlins depend on the distance of the column (usually from 1 - 1.4m) and the load of the building.

- Corrugated iron roof and corrugated iron cover the factory: The roof is usually steel. It has the effect of insulating as well as preventing noise in the factory.

- Light roofing sheets: Light-layer sheets have the effect of absorbing daylight to save energy for lighting the factory. Bright roofing sheets have many types for businesses to choose

- Sky door: It plays a role as ventilation for the factory and gets light to create a cool space as well as save energy used in the factory.

- Wall surrounding the factory: Surrounding the factory has the effect of shielding the space inside the workshop.

- Bracing: Bracing system includes roof bracing, purlin bracing, and gable bracing. A bracing system use increase the connection capacity for the parts of the building, helping the entire structure of the frame to be stable during the construction period.

- Canopy roof: Canopy roof system is a layer of corrugated iron, glass, or aluminum panels that is added to the building to protect the factory from the rain and sun as well as bring aesthetic effects to make the building more beautiful.

- Troughs and drainage pipes: Troughs are placed along both sides of the roof so that rainwater can quickly drain from the roof, and the drainage pipes use bring rainwater down to the sewer system.

- Lightning rod: It uses takes lightning to the ground, ensuring the safety of the entire building and the machinery and equipment inside.

>>> Read more: Factory design services and construction in Vietnam 2024

2. What are the advantages of a 10,000m2 industrial factory?

Why should businesses build an industrial factory of 10,000m2? What are the advantages that make this type of factory stand out from other types?

- The 10,000m2 industrial factory model is applicable to many types of areas so that businesses can choose from many models such as multi-storey factories, single-storey factories, factory combined with offices.

- The 10,000m2 industrial factory with flexible purposes can build an industrial textile factory, a mechanical industrial factory. This type of steel frame factory is easy to expand, upgrade and save installation time because there is no need for complex infrastructure.

- Build the factory by steel structure fabrication with a compact structure, so it does not take up much space and is highly durable and resistant to harsh weather.

3. What enterprise should choose an industrial factory of 10,000m2?

The 10,000m2 industrial factory model is a solution in terms of area for businesses to develop production lines. This factory is suitable for most small, medium, and large businesses. This factory type helps to meet a large amount of space to accommodate a production line's equipment, furniture, and labor. Business owners can also build the factory into a multi-storey structure to save land.

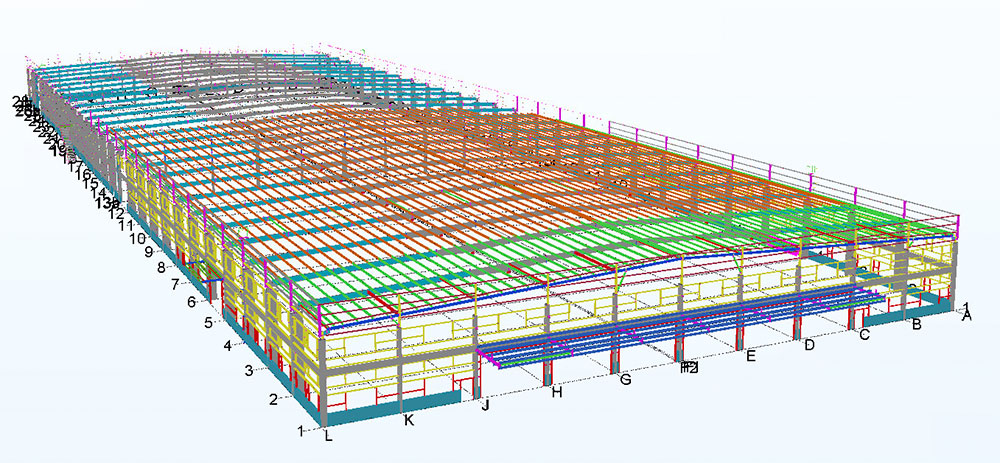

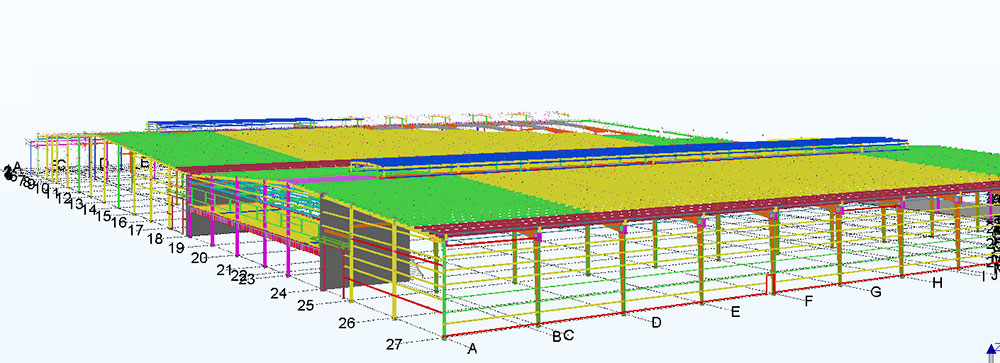

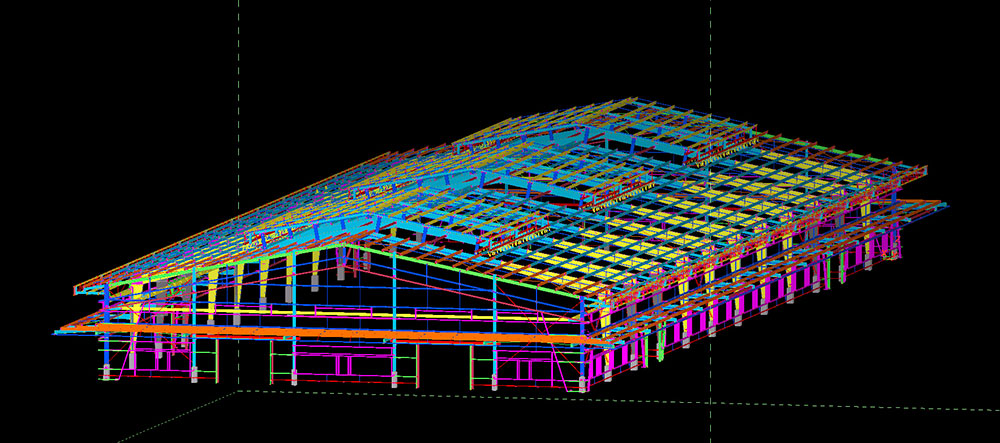

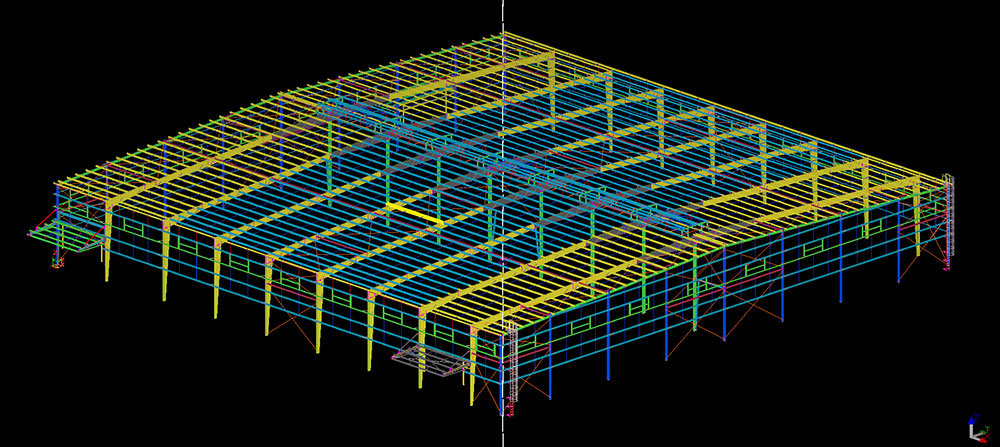

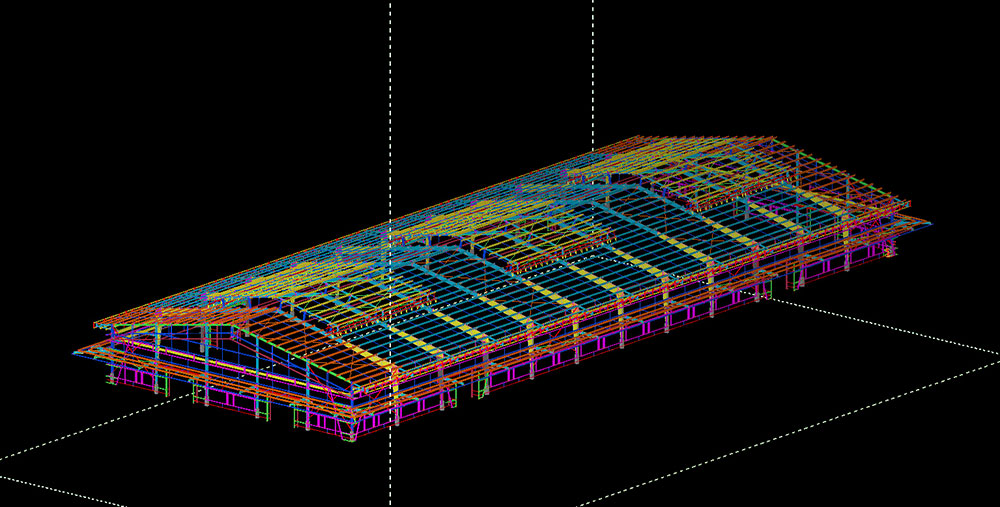

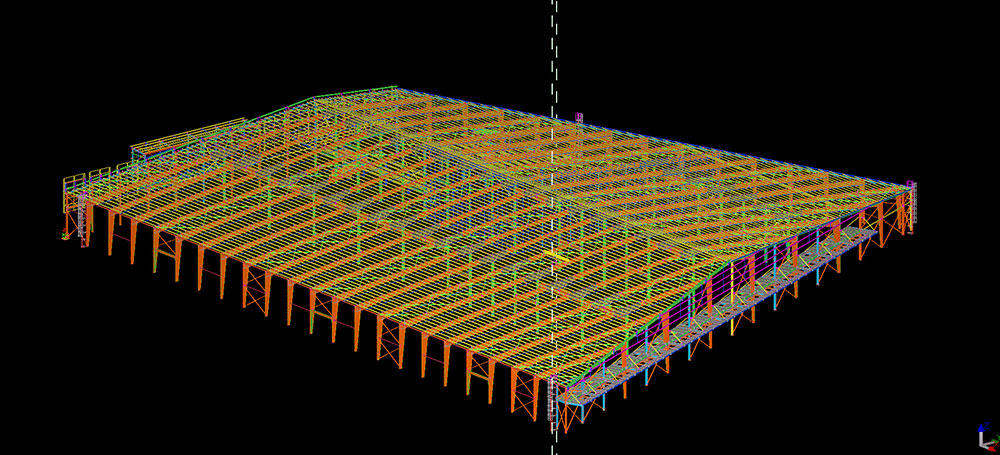

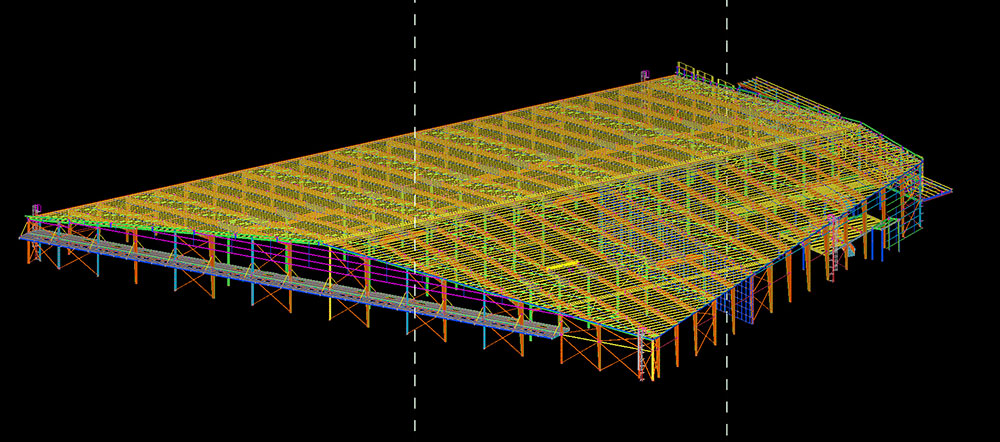

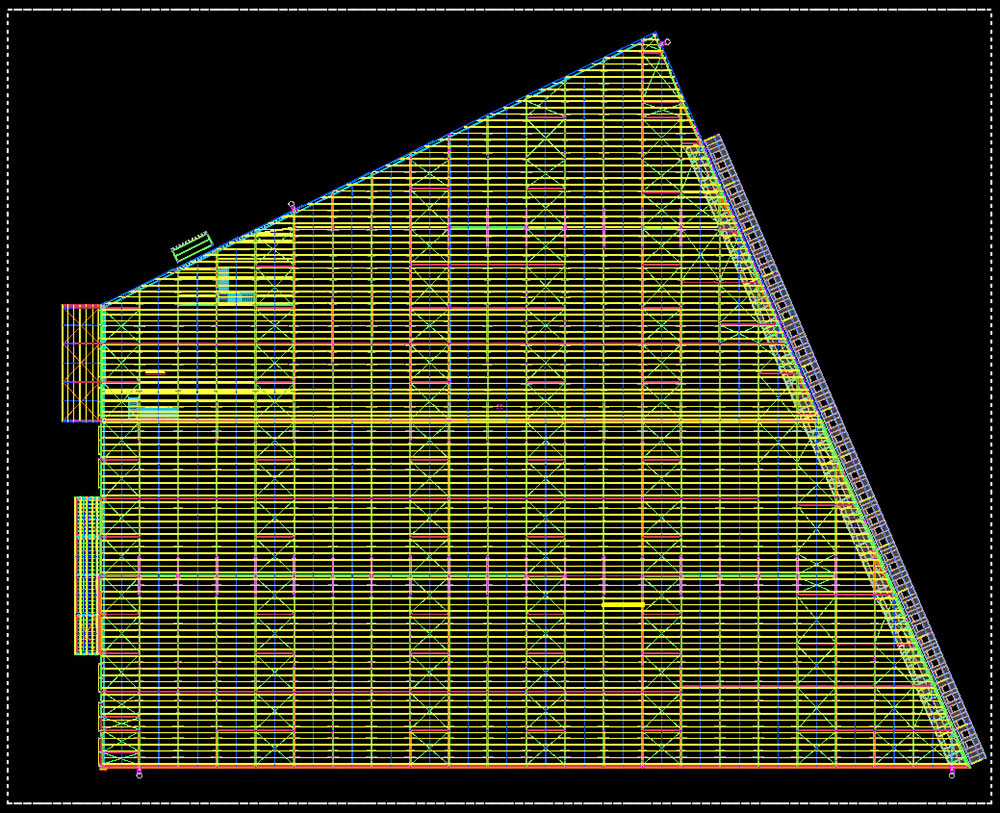

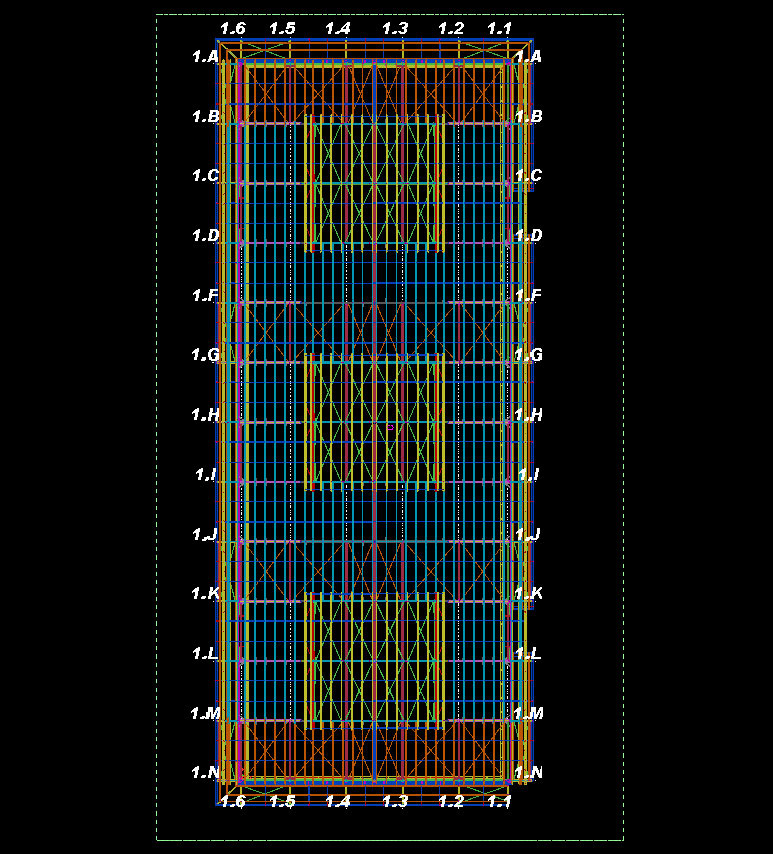

4. Samples of drawings for industrial factory 10,000m2

Below are some pictures of some 10,000m2 industrial factory drawings with many designs for your reference.

Hopefully, the article of BMB Steel has provided you with helpful knowledge and information to help businesses have more options in building an industrial factory of 10,000m2.