Comparison between flexible connections and rigid connections

In structural engineering, the choice of connection systems plays a vital role in determining the behavior and performance of a structure. Two commonly used connection types are flexible connections and rigid connections. While both serve the purpose of joining structural members, they differ in their ability to resist movement and transfer loads. This article aims to provide a comparison between two types of connections, highlighting their characteristics, applications, and advantages.

1. A brief introduction to the connection systems in steel structures

Steel structures are composed of several steel components such as columns, beams, trusses, bracing, etc. Each of the components has particular characteristics and advantages. They are connected together to form a complete and functional steel building or infrastructure.

Connection systems in steel structures are the systems of joints used to used to join steel components together. While there are a number of different connection methods, all of them play a crucial role in steel structures, offering several advantages that contribute to the overall performance and efficiency of the construction.

Here are some key advantages of connection systems in steel structures:

- Structural stability: Connection systems help the building withstand vertical loads and lateral loads by distributing these loads efficiently throughout the building, ensuring that the building remains stable.

- Load transfer: Connection systems facilitate the transfer of loads between steel components, minimizing the risk of overloading and maintaining structural integrity.

- Rigidity and stiffness: Connection systems provide the necessary connection points that allow steel members to act as a cohesive unit, contributing to the rigidity and stiffness of the structure.

- Safety and durability: Properly designed and executed connections are critical for ensuring the safety and long-term durability of steel structures.

- Construction efficiency: Connection systems in steel structures are designed to facilitate efficient and cost-effective construction processes.

2. Flexible connections and rigid connections

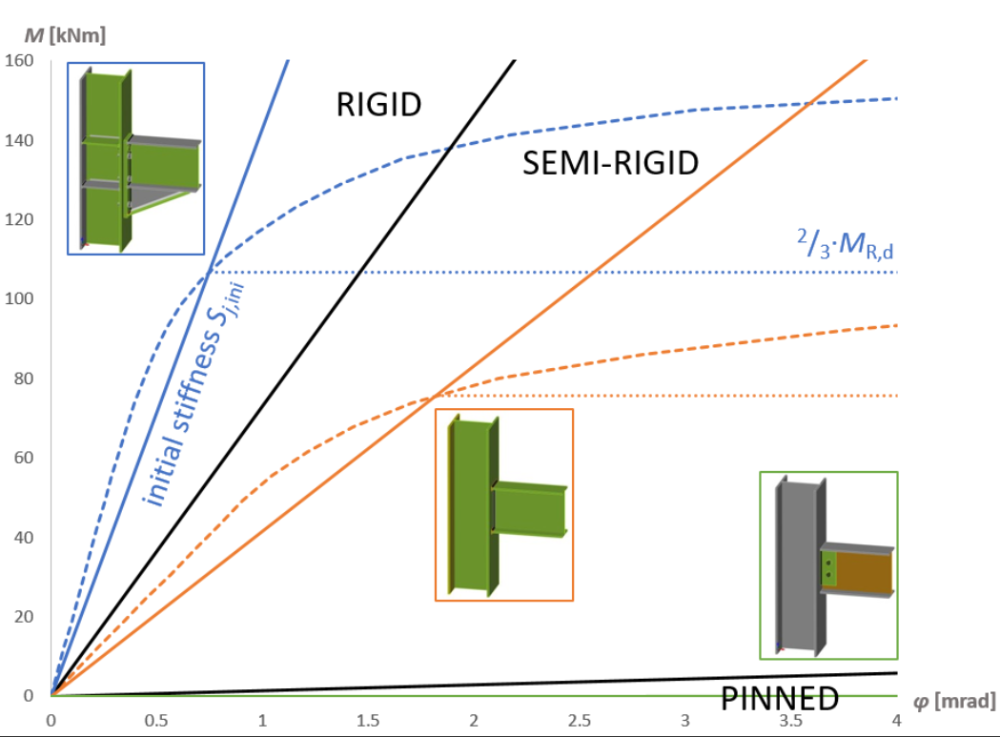

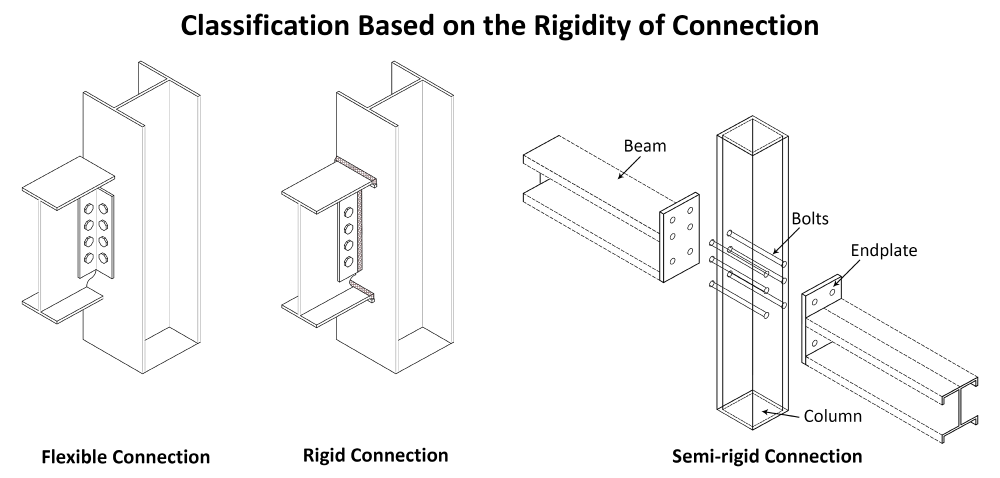

Steel connections can be classified into different types. One of the crucial factors to consider is connection stiffness. Connections can be categorized into two types: flexible connections (pinned connections) and rigid connections.

2.1 Flexible connections

Flexible connections allow relative movement between the connected members. They are designed to permit rotation or translation along one or more axes. While flexible connections do not resist moments and forces, they are capable of transferring axial and shear forces. Commonly achieved using bolts or pins, flexible connections are often employed in structures where some degree of movement or flexibility is desired. These connections can accommodate thermal expansion, deformations, and seismic forces. The advantages of flexible connections include ease of installation, adjustment, and disassembly if required.

2.2 Rigid connections

Rigid connections restrict relative movement between the connected members. They provide a rigid connection that resists rotation and transfers moments and forces between the members. Rigid connections are designed to transmit bending moments and shear forces without allowing significant rotation. These connections are achieved through welding, bolting, or a combination of both. Rigid connections are commonly used in structures where stability, strength, and resistance to lateral loads are required, such as frames or moment-resisting structures. The advantages of rigid connections include their high load-carrying capacity, stiffness, and ability to resist bending moments and shear forces. They provide enhanced stability, structural integrity, and resistance to external loads.

3. Comparison between flexible connections and rigid connections

Here are some differences between flexible connections and rigid connections:

3.1 Load transfer

Flexible connections primarily transfer axial and shear forces while allowing movement.

Rigid connections transfer both axial and shear forces, as well as bending moments, between the connected members. Rigid connections are more effective in transferring larger loads and resisting bending moments.

3.2 Movement and Flexibility

Flexible connections permit relative movement and flexibility between the connected members, accommodating deformations, thermal expansion, and seismic forces.

Rigid connections, on the other hand, restrict movement and provide greater structural stiffness and stability.

3.3 Design and Construction

Flexible connections, such as bolted connections, offer ease of installation, adjustment, and disassembly if required.

Rigid connections, particularly welded connections, require careful design and skilled construction techniques for proper execution.

3.4 Structural behavior

Flexible connections allow for the redistribution of forces and moments, providing a ductile response during extreme events.

Rigid connections offer a more predictable and stiff structural behavior, suitable for resisting lateral loads and maintaining structural integrity.

3.5 Application

Flexible connections are commonly used in structures where some degree of movement or flexibility is desired, such as trusses, bracing systems, or structures subjected to dynamic loads.

Rigid connections are preferred in structures that require stability, strength, and resistance to lateral loads, such as frames, high-rise buildings, or structures subjected to seismic forces.

Above is the comparison between flexible connections and rigid connections in steel structures. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.