Erection and installation company – Expert solutions for steel structures

In today's fast-paced construction environment, steel structure erection and installation services are critical in meeting project demands efficiently and effectively. As the demand for pre-engineered steel buildings continues to rise due to their cost-effectiveness, speed, and flexibility, choosing the right erection and installation company is essential for ensuring a successful build.

This article provides an in-depth look at the services, standards, and processes involved in steel structure erection and installation, with a special focus on BMB Steel, a leading contractor in Southeast Asia.

1. What is an erection and installation company?

An erection and installation company specializes in constructing and assembling pre-engineered buildings or steel structures. These companies handle all aspects of the construction process, from delivering materials to the site to installing structural components such as columns, beams, and roofing systems. They play a vital role in the completion of large-scale industrial projects like factories, warehouses, and commercial facilities.

At BMB Steel, we pride ourselves on being a leader in the steel structure erection and installation field, providing high-quality and reliable services throughout Vietnam and Southeast Asia. With our skilled team of engineers and advanced equipment, we have completed numerous projects, delivering excellent results to our clients.

2. Key components of steel structure buildings

Steel structure buildings are constructed from a variety of essential components designed to ensure strength, durability, and versatility. The primary components include:

- Mainframe (columns and beams): These are the backbone of the structure, providing the necessary support for the building's overall weight and load-bearing requirements.

- Secondary structural elements (purlins, girts, and bracing): These components help reinforce the main frame, adding stability and distributing loads more efficiently.

- Roof and wall panels: Pre-engineered steel panels are used to enclose the building, protecting it from the elements while maintaining structural integrity.

These parts are bolted and welded together during the erection process to form a solid, durable structure that can withstand various environmental conditions.

Each component is fabricated to precise specifications, ensuring seamless assembly at the construction site. These structures are highly adaptable and can integrate mezzanines, crane systems, and other custom features to meet project requirements.

3. Benefits of steel structure erection over concrete construction

When compared to traditional concrete construction, steel structure erection offers several advantages:

- Time-saving: Steel erection takes about half the time of concrete construction. For example, a two-story building that would take two months to complete using concrete can be finished in just one month with a steel structure.

- Cost efficiency: Pre-engineered steel buildings are more cost-effective since most components are prefabricated in the factory, reducing on-site labor costs and construction time.

- Flexibility and adaptability: Steel components are easier to modify and expand. If weather conditions hinder the erection process, construction can be paused and resumed more efficiently compared to concrete structures.

4. BMB Steel’s erection and installation process

At BMB Steel, we follow a meticulous and highly organized process to ensure the success of every project. Our erection and installation workflow includes the following steps:

4.1 Temporary facilities setup

We establish temporary facilities to support the construction process, such as site offices, warehouses, roads, and material storage areas.

4.2 Material handling, unloading, and preservation

We handle the transportation, unloading, and preservation of construction materials on-site, following strict safety processes to prevent damage.

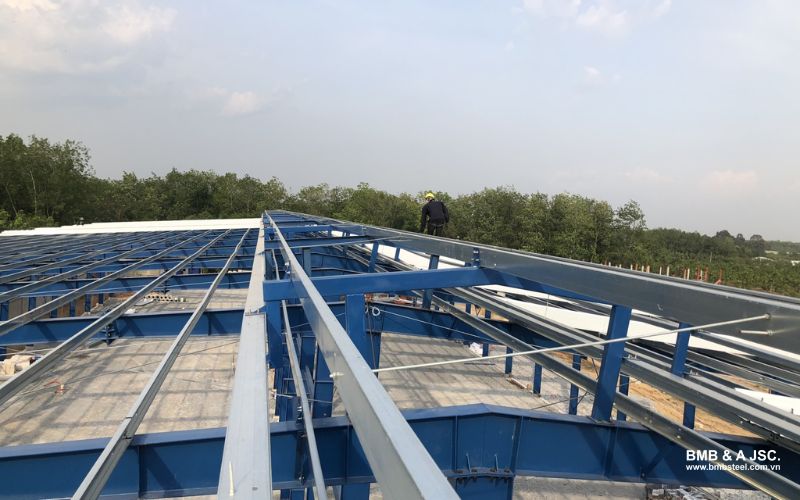

4.3 Main steel structure erection

The main structural components, such as columns, rafters, and beams are assembled and erected, adhering to precise technical and design specifications.

4.4 Roof and cladding installation

Once the main structure, braces, and purlin/girt are completed, roofing and cladding are installed to enclose the building and protect it from weather conditions.

4.5 Final inspection and handover

A comprehensive inspection is carried out, and the final touches are completed before handing over the project to the client.

4.6 Warranty Service

After the handover, BMB Steel monitors the project and provides warranty services as per the agreed terms.

4.7 End of warranty period

Upon completing the warranty period, we conduct a final review to ensure the building meets all quality standards.

With this meticulous and transparent process, BMB Steel is committed to delivering high-quality, safe, and durable steel structure projects for its clients.

5. Factors influencing the cost of erection and installation

Several key factors affect the overall cost of erection and installation services:

- Project size: Larger projects require more materials and labor, complicated erection, increasing the overall cost.

- Building type: Different types of buildings (industrial, commercial, or residential) come with varying complexity, affecting the price.

- Location: The distance to the construction site can influence transportation costs and logistics.

- Materials used: The type of steel and additional coatings, such as fireproofing or anti-corrosion treatments, can raise costs.

At BMB Steel, we offer competitive pricing, tailored to your project’s specific requirements. Our goal is to provide transparent cost estimates with no rise in fees.

6. Key preparations for erection and installation projects

Before beginning any erection and installation project, there are several critical steps to ensure success:

- Site preparation: Proper layout and space allocation based on the current project plan and potential future expansions.

- Design approval: Finalizing structural designs, ensuring they meet the project’s technical and aesthetic requirements.

- Material selection: Ensuring all components comply with relevant safety and construction standards.

- Cost optimization: Analyzing every aspect of the project to maximize savings while maintaining quality.

By adhering to these steps, BMB Steel ensures smooth and efficient construction, minimizing delays and budget overruns.

7. Why choose BMB Steel as your erection and installation company?

With years of experience in the field, BMB Steel stands out as a trusted partner for steel structure erection and installation projects. We combine cutting-edge technology, skilled labor, and customer-focused service to deliver exceptional results on every project.

From industrial plants to large warehouses, BMB Steel has the expertise to manage every aspect of your construction, ensuring the final structure is both durable and cost-efficient.

Choosing the right erection and installation company is crucial to the success of your steel structure project. BMB Steel provides comprehensive services, from initial design to final handover, ensuring that each project is completed with the highest standards of quality, safety, and efficiency. Contact us today for a detailed consultation and discover how we can assist with your next steel structure construction project.