A guide to steel structure welding. Methods and inspection techniques

Steel structure welding is a vital process in construction, manufacturing, enabling the seamless joining of steel components for strength and durability. This guide dives into the essentials of steel structure welding. You'll learn about inspection standards to guarantee the integrity of every weld. Explore the details with BMB Steel in this article!

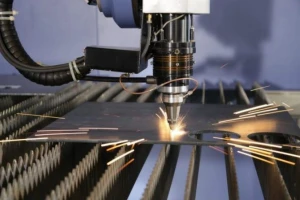

1. What is steel structure welding?

Steel structure welding is a process joining steel components

Welding is the process of using heat from a flame or an electric arc to heat a small portion of metal at the point of contact, causing the metal to melt and fuse together. As it cools, the metal solidifies, forming a strong and durable weld.

Steel structure welding is a technical process applied in construction and manufacturing industries to join steel components together.

2. Steel structure welding methods

2.1. Manual arc welding

Manual arc welding is a common method that uses electric current to create an electric arc between the welding electrode and the metal surface to be welded. The heat generated by the electric arc, reaching temperatures above 2000°C, melts both the welding electrode and the base steel edge (with a melting depth of about 1.5-2 mm).

The molten metal from the welding electrode forms small droplets, drawn into the weld groove by the electric field, mixes with the molten base steel. As the mixture cools, it solidifies to form a weld.

The essence of the weld lies in the tight molecular bond between the melted metals. This weld has strength and load-bearing capacity equivalent to the original steel.

2.2. Automatic and semi-automatic arc welding

Automatic and semi-automatic arc welding methods offer high productivity, ensure the mechanical properties of the weld, save electrical energy.

2.2.1. Automatic arc welding

The automatic welding method operates on the same principle as manual welding but uses a bare welding wire instead of a flux-coated electrode. Flux is pre-applied as a thick layer on the weld groove. The welding wire is gradually fed by the machine at an appropriate speed as the welding machine moves steadily.

Key advantages:

- High welding speed: With high current intensity (600-1200 amps), the welding speed can be 5-10 times faster than manual welding.

- High weld quality: The deep groove ensures a strong weld with a smooth surface. The molten metal is covered by a thick flux layer, allowing gas bubbles to escape and creating a dense, durable weld.

- Work safety: The electric arc burns beneath the flux layer, minimizing health risks for welders.

2.2.2. Semi-automatic arc welding

Semi-automatic welding is widely used with soft tubular or flat welding wires. The metal casing of the welding wire is 0.2-0.5 mm thick, filled with flux inside. This method is both convenient and highly efficient for structural steel fabrication.

3. What is stainless steel?

Stainless steel is an alloy of iron and carbon. What sets it apart is the addition of at least 10.5% chromium, which provides the material with its signature corrosion resistance. This makes stainless steel ideal for applications where durability and resistance to rust or staining are crucial.

There are 5 main types of stainless steel, but fabrication shops commonly work with 3: austenitic, martensitic, and ferritic stainless steel. Among these, austenitic stainless steel is the most widely used. Martensitic stainless steel is preferred for hard-facing applications, while ferritic stainless steel, known for being cost-effective, is frequently used in consumer goods.

4. Common stainless steel welding methods

4.1. Metal inert gas welding method (MIG)

- Metal inert gas (MIG) welding is one of the most widely used welding techniques, favored for its relatively low initial investment cost. The primary equipment required includes a gas cylinder, regulator, wire feed unit, power source, MIG torch.

- To achieve a successful weld, a suitable weld groove must be prepared. This groove provides space for the molten weld metal to fill. Additionally, the welding electrode, which carries the electrical current, must be clean and free from contaminants like oil.

- In the MIG process, a wire welding electrode is automatically fed through a welding gun, creating an arc with the workpiece. The heat from the arc melts the materials, forming the weld. This process is carried out under the protection of an inert shielding gas, such as argon, carbon dioxide, helium, which prevents contamination from the surrounding atmosphere.

- MIG welding is versatile and effective for joining metals, including stainless steel, mild steel, low-carbon steel, aluminum, both thin and thick plate metals.

4.2. Gas tungsten arc method (TIG)

- Gas tungsten arc welding (TIG) is a widely popular technique. Today, TIG welding is used for metals, including stainless steel, brass, aluminum, bronze, even precious metals like gold.

- Similar to MIG welding, TIG welding relies on an inert shielding gas to protect the weld area from contamination. However, the key difference is that TIG welding uses a non-consumable tungsten electrode instead of a consumable wire.

- In this process, an electric current flows through the tungsten electrode, generating heat to melt the base material. The arc created melts the filler wire, forming a weld pool. TIG welding generates lower heat than other methods, making it ideal for thin workpieces and intricate welds. Commonly welded materials include stainless steel, alloy steel, non-ferrous metals such as aluminum, magnesium, copper alloys.

4.3. Stick or shielded metal arc welding method (SMAW)

- Shielded metal arc welding, often known as stick welding, is one of the oldest and most manual welding methods. It remains widely used due to its simplicity and cost-effectiveness.

- In stick welding, a consumable electrode coated in flux is used. The flux coating prevents the arc from becoming unstable and shields the weld area from atmospheric contaminants. This feature makes stick welding particularly suitable for outdoor, drafty environments.

- Stick welding is limited in its application to metals thinner than 18 gauge, and post-weld cleanup is typically required to remove slag.

- Unlike MIG and TIG welding, stick welding does not require shielding gas, which makes it the most affordable method. However, it is generally better suited for repairs, maintenance rather than large-scale industrial projects.

5. Steel weld inspection methods

After completion, structural steel welds must undergo the following 6 standard inspection methods:

5.1. Visual inspection

- The weld must be free of surface cracks and defects in the molten metal areas.

- Defects such as bumps, undercuts, burn-throughs, lack of fusion, misaligned edges must not be present.

- The size, shape, reinforcement of the weld must meet standard specifications with no deviations exceeding permissible limits.

5.2. Metallurgical inspection

- The weld must not contain cracks in the molten metal zone, heat-affected zone.

- Lack of fusion between weld layers and the edges must not occur.

- Incomplete weld penetration at the weld root must not exceed 15% of the wall thickness or 3 mm (for walls thicker than 20 mm).

- The number of pores must not exceed 5 per 1 cm², with individual pores no larger than 1.5 mm in diameter and a total size not exceeding 3 mm.

- There must be no cracks, fissures that would reduce the elasticity and ductility of the weld.

5.3. Hydraulic testing

- The weld must be free of cracks or signs of water leakage.

- No significant deformation should occur during the test.

5.4. Tensile strength testing

- The average tensile strength values from test samples must not be lower than the minimum tensile strength of the corresponding steel.

- No test sample result may fall below 10% of the steel's minimum tensile strength.

5.5. Bend testing

|

Minimum bend angle |

|||

|

Sample thickness ≤ 20 mm |

Sample thickness > 20 mm |

Sample thickness ≤ 12 mm |

|

|

Carbon steel |

100o |

100o |

70o |

|

Low-alloy steel with manganese, silicon-manganese |

80o |

60o |

50o |

|

Low-alloy steel with chromium-molybdenum, chromium-molybdenum-vanadium |

50o |

40o |

30o |

|

High-alloy steel with chromium |

50o |

40o |

30o |

|

High-alloy steel with chromium-molybdenum |

100o |

100o |

30o |

5.6. Impact toughness testing

|

Minimum impact toughness |

||

|

Ordinary steel |

Austenitic steel |

|

|

20°C |

49,05 Nm/cm² |

68,67 Nm/cm² |

|

< 0°C |

19,62 Nm/cm² |

29,43 Nm/cm² |

Steel structure welding plays a critical role in various industriess. Whether using manual, automatic, specialized methods like MIG or TIG for stainless steel, understanding the techniques and inspection processes is essential. Mastering steel structure welding is key to achieving long-lasting and efficient structural designs.

We hope this article has provided you with valuable information about steel structure welding. Don’t hesitate to contact BMB Steel for support from our team of experts.