Advantage of cold-formed steel in pre-engineered steel building construction

Pre-engineered steel buildings have gained popularity in the construction industry due to their numerous benefits. Within this realm, cold-formed steel plays a crucial role. Cold-formed steel offers numerous advantages in the construction of pre-engineered steel buildings. In this article, we will explore the advantages of cold-formed steel and its impact on the performance and success of pre-engineered steel buildings.

1. A brief introduction to the pre-engineered steel building concept

Pre-engineered steel buildings refer to structures that are designed, fabricated, and assembled using standardized components and methods before being transported to the construction site. These buildings are engineered to meet specific requirements and are manufactured off-site, allowing for faster and more efficient construction processes.

The components of pre-engineered steel buildings, such as columns, beams, and panels, are fabricated in a factory and then assembled on-site. This construction method provides numerous advantages, including cost-effectiveness, customization options, durability, and compliance with building codes and regulations. Pre-engineered steel buildings have gained popularity in various industries to meet the unique needs of different applications.

2. Information about cold-formed steel

Cold-formed steel is a construction material that is shaped by bending, rolling, and forming thin sheets of steel at room temperature, without the use of heat. It is commonly used in a variety of building applications, ranging from residential and commercial buildings to industrial and infrastructure projects.

Below is some information about cold-formed steel:

Manufacturing process:

- Cold-formed steel is typically manufactured through a series of processes, including roll forming, press braking, folding, and punching.

- Sheets of steel, often referred to as coils, are passed through a series of rollers to shape them into specific profiles and sections.

- The steel is cold-worked and shaped at room temperature, resulting in increased strength and durability.

Material properties:

- Cold-formed steel is primarily made from low-carbon steel or galvanized steel, which provides corrosion resistance.

- The thickness of cold-formed steel sheets can range from 0.5mm to 3mm, depending on the specific application and structural requirements.

- The material properties of cold-formed steel, including its strength, ductility, and stiffness, can vary depending on the specific grade and thickness used.

Applications of cold-formed steel:

- Residential buildings: Cold-formed steel is commonly used in the construction of residential buildings, including detached houses, multi-story apartments, and townhouses.

- Commercial and industrial buildings: It is widely employed in the construction of commercial and industrial structures, such as offices, retail spaces, warehouses, and manufacturing facilities.

- Infrastructure: Cold-formed steel finds applications in infrastructure projects, including bridges, tunnels, and modular structures.

- Interior systems: It is used for interior partitions, suspended ceilings, roofing systems, and other non-structural elements.

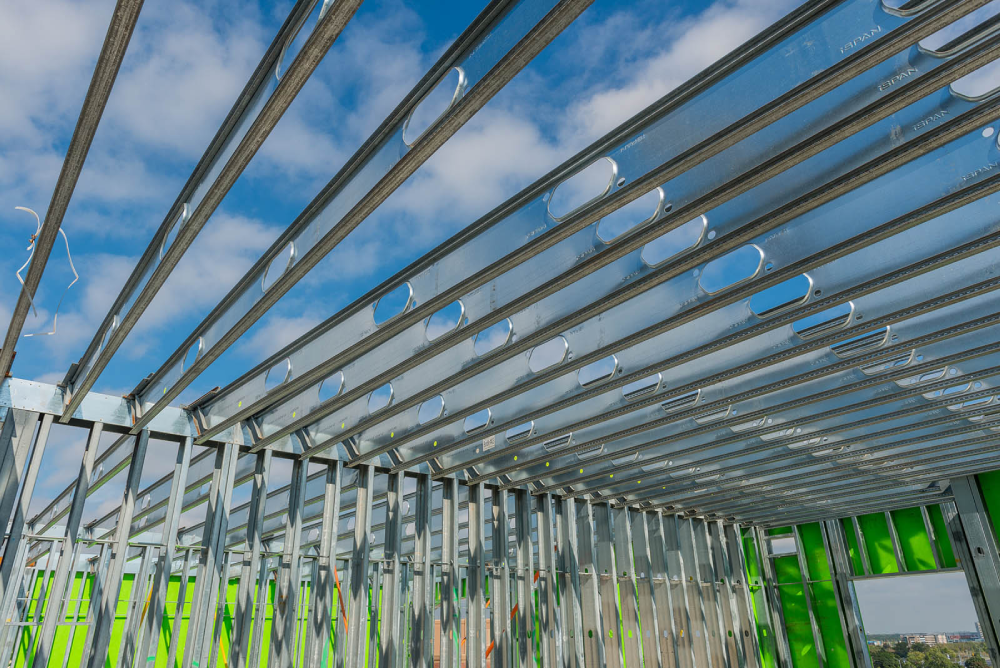

Application of cold-formed steel

Ongoing research and development:

- Ongoing research and development efforts are focused on improving the performance, efficiency, and sustainability of cold-formed steel structures.

- Advancements include the development of high-strength, lightweight steel alloys, improved connection systems, and enhanced fire-resistant coatings.

3. Advantages of cold-formed steel in pre-engineered steel building construction

Cold-formed steel is commonly used in the construction of pre-engineered steel buildings, as it offers several advantages.

3.1 Cost-effectiveness

One of the primary advantages of cold-formed steel in pre-engineered buildings is its cost-effectiveness. Cold-formed steel components can be manufactured in large quantities at a lower cost compared to other construction materials. The efficient manufacturing process, coupled with its availability, makes cold-formed steel an economical choice for pre-engineered steel buildings.

3.2 Lightweight construction

Cold-formed steel is a lightweight material, making it easier to handle, transport, and install during the construction process. Its light weight reduces the need for heavy equipment and simplifies logistics, resulting in cost savings. Additionally, the reduced weight of cold-formed steel structures allows for more flexible foundation designs, potentially lowering foundation costs.

3.3 High strength-to-weight ratio

Despite its lightweight nature, cold-formed steel exhibits remarkable strength. It has a high strength-to-weight ratio, meaning it can bear significant loads and stresses while using less material compared to other construction materials. This advantage allows for the creation of efficient structural systems and designs that maximize strength while minimizing weight.

3.4 Design flexibility

Cold-formed steel offers exceptional design flexibility, enabling architects and engineers to realize their creative visions. It can be easily shaped and formed into various profiles and sizes, allowing for unique architectural features and efficient structural configurations. The flexibility of cold-formed steel enables the creation of custom designs and facilitates the integration of complex building systems.

3.5 Durability and Resilience

Pre-engineered steel buildings constructed with cold-formed steel are highly durable and resistant to various environmental factors. Cold-formed steel is inherently resistant to corrosion, pests, fire, and moisture. It maintains its structural integrity over time, ensuring the longevity and low maintenance requirements of the building. Cold-formed steel structures also exhibit excellent performance in extreme weather conditions, such as high winds, seismic events, etc.

3.6 Speed of construction

The prefabricated nature of cold-formed steel components enables faster construction timelines for pre-engineered steel buildings. These components can be manufactured off-site and quickly assembled on-site, reducing construction time and associated costs. The shortened construction schedule also minimizes project disruptions and allows for earlier occupancy or utilization of the building.

Above is some information regarding the advantages of cold-formed steel in pre-engineered steel buildings. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.