Latest design standards for industrial factory

- 1. Standards of the factory floor

- 2. Standards of the factory foundation

- 3. Roof and roof door

- 4. Walls and partitions

- 5. Windows, doors

- 6. The thermal expansion joint

- 7. Stairs

- 8. Floor

- 9. Ancillary works

- 10. Tunnels - canals

- 11. Platforms and viaducts

- 12. Conveyor corridor

- 13. Bunke

- 14. Silos and silos block

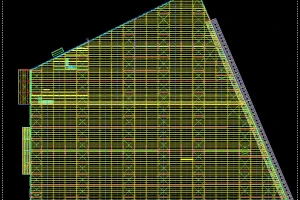

- 15. Support for landing stage of scaffold and mezzanines

- 16. Chimney

- 17. Electrical system

- 18. Water supply and drainage

- 19. Ventilation and air conditioning

How to design a factory with reasonable standards? What are the popular design standards for industrial factories in VietNam? In this article, BMB Steel will introduce to you some information about the latest standard factory design standards.

1. Standards of the factory floor

Recently, when designing factory floors with TCVN 2737: 1995 standards, the contractor has to survey and comply with the fundamental principles on the impacts of topographic, geological, and hydrogeological conditions. Besides, it is vital to prepare suitable geological plans before conducting the construction.

The factory floor includes the following types:

- Concreted floor

- Reinforced concrete floor

- Concrete floor with impact-resistant steel billet

- Concrete floor with the resistance to acid and alkali corrosion

- Cement tiled floor; steel floor

- Wood and plastic plank floor

- Asphalt concrete floor

Each category will be applied with each project's requirements or technological capabilities.

The concrete floor will be designed in each cell with a length of less than 0.6m. The space between each cell should be inserted by bitumen. The lining concrete thickness must have a minimum thickness of 0.1 m. The factory floor is flat, sturdy and effective in draining water.

2. Standards of the factory foundation

A firm and stable factory foundation must meet the standards prescribed by TCVN 2737: 1995. The foundation is an integral part supporting the whole building, so it is designed to withstand the impacts from topographical factors. The foundation is required to meet these following criteria:

- The floor must be higher than the elevation of the foundation. The height of steel columns, the columns with a wall frame and the concrete columns is 0.2m, 0.5 m and 0.15m, respectively.

- For construction that needs to be expanded, the column foundation should be designed altogether adjacent to two columns

- When designing, the foundation must be protected with insulation and rusting materials in order not to affect the foundation structure.

3. Roof and roof door

It is crucial to choose the right materials to create the slope for the roof:

- The slope of the cement roofing sheet is 30% - 40%.

- The slope of the standard corrugated iron roof is 15-20%

- The slope of the reinforced concrete standard roof is 5% - 8%

Depending on the type of factory, it is possible to install the drainage system for the factory inside or outside. The inner water trough system is required to have an additional cover to allow water to flow along the ditch. If the factory is a one span structure with a low column height and small width, it is possible to let water flow freely from the roof. But for buildings higher than 5.4 m, it is mandatory to install a system of down troughs.

For the design of the roof door:

- The maximum length of the roof door is 48m

- The minimum thickness of glass is 3mm and it must be fixed

- In many cases, people do not install the roof door because other auxiliary designs also ensure light and ventilation.

4. Walls and partitions

Some design standards for pre-engineered steel buildings include:

- Force-bearing wall

- Infilled wall

- Self-bearing wall

The skirting design must include the bitumen, mortar or cement waterproofing bricks. The moisture-proof layer at the foot of the wall must be made of cement mortar 75 with a 20 cm thick and placed horizontally on the finished floor

Partition walls between factories should be convenient for assembling and disassembling to meet the requirements of changing technology and repairing equipment.

We can use materials like wood planks, steel mesh, concrete, plywood panels, etc to make the partitions. For manufacturers with span sizes less than or equal to 12m, the column height is not greater than 6m to ensure the load-bearing capacity of the wall.

5. Windows, doors

A standard factory door are required to meet the following categories:

- The door must open to the outside

- The height and width is spacious enough for vehicles. With the height less than 20cm and the width less than 50cm

- The height of the door from the bottom to the right is less than or equal to 2m4

- Windows or doors are required to ensure to have enough natural light for the factory. Besides, it must be spacious for easy movements.

6. The thermal expansion joint

- The thermal expansion joint is designed with a space between two joints less than 60m.

- If the factory is built in an earthquake-prone area of level 7 or higher, the expansion joint must coincide with the earthquake-resistant joint.

- The design of thermal expansion joints of the load-bearing structure should be separate from the height structure from the foundation to the roof.

7. Stairs

- According to factory design standards, the stairs will be made of reinforced concrete, with a 1:2 inclination, each step must be designed with a width of 300mm and a height of 150mm.

- The inclination ratio of stairs without cabin is 1:1

- Stairs can be designed vertically with a width greater than 0.6m

- Design an outdoor staircase to make an escape exit for unexpected incidents

- The height for handrail must be more than 0.8m

8. Floor

- The floor must be made of reinforced concrete to withstand the impacts of the outside

- Designing a separate pedestal is mandatory to avoid excessive pressure

- The floor frame should be made of steel

9. Ancillary works

- Ancillary works must be designed according to certain blocks

- The position should not be at the end of the wind direction relative to the building

- The production area must have ventilation and lighting systems.

10. Tunnels - canals

- The distance between the entrance door and the technical network is required to be equal or less than 100m

- Doors must had railing and placed outside the transport area

- The position of the door must be designed so that it does not affect the transportation

- The sump and water drainage are required

11. Platforms and viaducts

- According to the factory design standard TCVN 4604:2012, viaducts are classified according to each function

- Regulations on bridges and pipelines need to pay attention to check the load

- The viaduct supporting the railway branch has a standard height of 1.8m; 3.1m; 6m; 9m. If you want a higher design, you must have all documents with appropriate reasons to be approved.

- Careful calculation of the load for the stable operation of the track.

- The path must have paving slabs

- Viaduct tank has a slope of 0.2%

12. Conveyor corridor

- The distance between the centers of the corridor is 12m, 15m, 18m, 24m, 30m

- The maximum distance between conveyor doors is 100m

- The ladder has a 60 degree inclination

- Conveyor corridor is designed with a height of a multiple of 6M compared to the ceiling floor, for the basement floor is a multiple of 3M

- Corridor dust can be cleaned with compressed air by hydraulic methods and provided with drainage system

- Conveyor corridor must have a natural ventilation system

13. Bunke

- Preferably use reinforced concrete

- Calculation and design of the mouth in a symmetrical form

- Bunke has a less than 80% computational capacity.

- The corners inside should be rounded

- Flame retardant materials is used for the outer layer

14. Silos and silos block

- It is prior to use reinforced concrete material

- It is required to use non-combustible material for the main

- The cross-section is designed in a circle with a 3m diameter, possibly square

- Between the length and width, the ratio of the silo blocks is less than 3.

- Ensure at least two exits for silos

- In the middle of the silo, a discharge mouth must be arranged

15. Support for landing stage of scaffold and mezzanines

- The formulas are 6m x 6m and 6m x 9m (column step) for floor racks and mezzanines. The multiple is 12M for the rack height, more than 4.8 m. The multiples of the landing stage of the scaffold is 6M.

- For fire resistance levels I and II, it is recommended to design with non-combustible materials.

- For buildings with fire resistance level III and IV, it is prior to use non-combustible materials

- Materials with flame retardant paint and a fire resistance limit of 0.75h with steel structures are required

16. Chimney

- For brick chimneys, the diameter is more than 0.8m, for reinforced concrete chimneys, the diameter is not less than 3.5m.

- The height of the chimney is less than 60m

- Steel chimneys must have stiff braces

- For factory design standard TCVN 4604:2012, the inside surface of the chimney must have a protective layer

- Outside the chimney, there must be a system of lightning and lighting protection

- There must be an expansion joint between the air duct and the chimney

- The shape of the chimney depends on the project

17. Electrical system

- Depends on requirements and technology capabilities

- Selection of materials for electrical systems must meet the surrounding conditions

- You should select equipment with optimal standards

- Select wiring sockets working at a maximum voltage of 36V

18. Water supply and drainage

- Consult experts to design internal and external water supply and drainage systems

- Geological and hydrogeological survey is essential to determine the coordinates of drainage position

- Classify types of wastewater

- The rainwater drainage ditches must have covers.

19. Ventilation and air conditioning

- Based on the working and technological conditions to design ventilation and air conditioning.

- Taking advantage of natural air is highly recommended

- The natural ventilation system must ensure that the partitions and walls are reasonable to create alternating airflow.

- Use mechanical methods to clean air dust only under certain circumstances.

- A protective air-conditioning is required for high-temperature cockpits.

The article above is the information about the latest factory design standards. BMB Steel hopes that with this information, businesses and contractors can complete more gorgeous and high-quality buildings