BMB Steel is a top-ranking construction company in Vietnam

The infrastructure system’s rapid development is facilitating construction companies’ impressive growth. For construction companies in Vietnam, BMB Steel is considered a top-ranking one that offers customers excellent products at reasonable prices. Let’s go through this paper to learn more about the company.

1. An overall look at BMB Steel Company

BMB was founded in 2004, with its first factory built in Binh Duong Province. Until now, it has opened a number of branches and representative offices along Vietnam as well as in other countries such as Cambodia, Myanmar, the Philippines, Indonesia, and so on.

With the mission of transmitting Vietnamese knowledge to the world through its achievement, together with partners building a bright future, BMB Steel commits to providing customers with excellent products and services at reasonable prices.

Throughout its progress, the company has been making continuous innovations in order to meet unlimited customer requirements.

2. The manufacturing procedure of BMB Steel Company

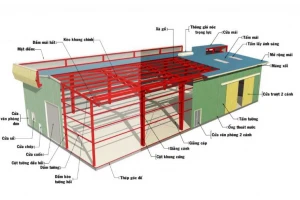

In order to create a respectable construction that meets the requirements of owners, BMB obeys strict procedures with different stages: Designing, Reinforcing and Assembling. During the process, BMB ensures to protect the whole construction and construction worker and architects in safety by learning thorough notes when designing and designing projects.

2.1. Designing Stage

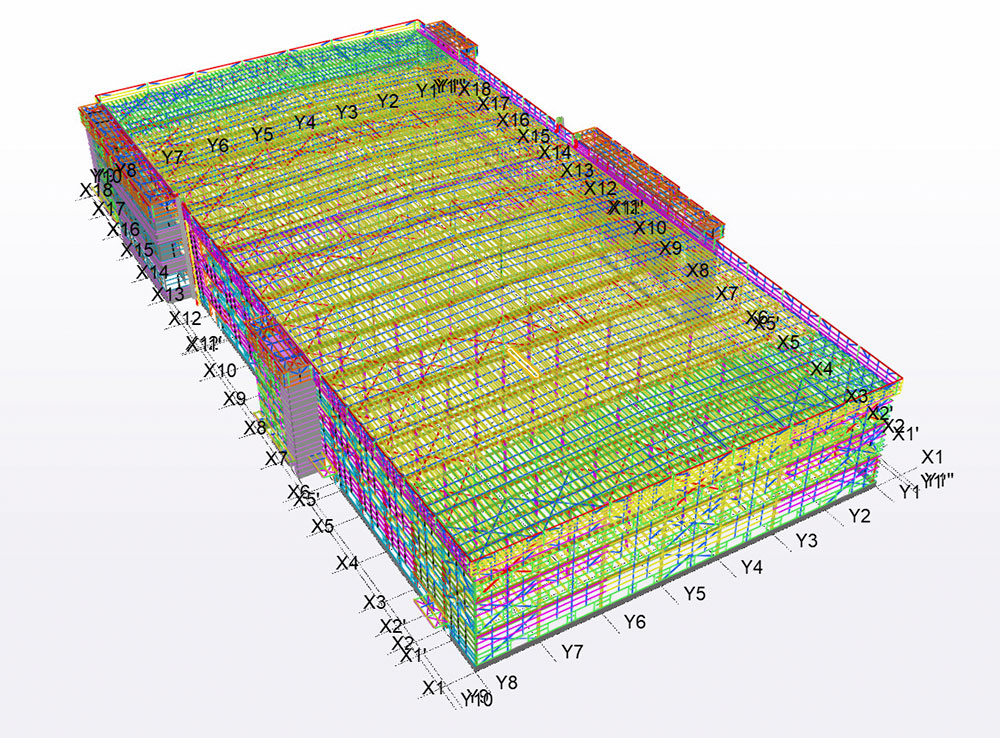

Basic drawing

Each construction process starts with a basic drawing. Firstly, BMB creates basic drawings based on the specific requirements of customers. Architects then display those ideas as technical parameters according to required standards. This initial step is the foundation of the whole process.

Preliminary Design

After the Basic Design Stage, architects move on to preliminary drawing, which displays the owners’ initial ideas about the constructions. Besides, the process includes selecting materials and the technological system and determining the goals and purposes of the construction.

Detailed Design and Shop Drawing

Detailed drawing gives the most thorough description of the construction. The drawing consists of information from significant structure to minor details. It is what engineers and architects can use in practical applications and can be used for the acceptance stage. The drawing must strictly follow designing standards such as AISC 360-10, AISC 360-16, ANSI C-201, UBC 1997, and so on.

2.2. Reinforcing Stage

Selecting and Inspecting Raw Material

Based on the drawings above, BMB carefully selects raw materials that work best in the structure. Before bringing them into practice, BMB conducts a thorough inspection, for example, on origin, quantity, hardness, endurance, and especially processing ability.

CNC Cutting and Manual/Automatic Welding

Engineers use a CNC Cutting Machine to cut the steel under the control of the computer. Then they use manual forces or automatic mechanism systems to weld steel materials together.

Using Hydraulic Cutting Machine, Straightening Reinforcing Bars, and Sharpening

Engineers then use Hydraulic Cutting Machine to cut steel materials and straighten reinforcing bars in sharpening materials so that they eliminate mistakes caused by the welding process and make materials in the accurate size and shape required

Conducting Non-Destructive Testing on Welding Positions and General Testing

The process includes finding and eliminating defective products. Not until the products meet requirements and standards does general testing end.

Applying Finish Painting, Cleaning, Doing Surface Preparation

Engineers finally clean the processed materials and paint them with Finish Painting.

Packaging and Delivering

Finally, products are packaged and delivered to the construction site.

2.3. Erection of Pre-Engineered Steel Stage

Fixing Anchor Bolt

The engineers carefully choose anchor bolts that fit the drawings to ensure there will be no risk and danger during the process.

Installing Steel Truss Frame

Installing a steel truss frame is a crucial step, it is important to make the frame as solid and securely as possible.

Roofing with Corrugated Sheet Metal and Accessories

The next step will be roofing the steel structure with corrugated sheet metal and other necessary accessories.

Finishing

The finishing step includes inspecting the safety quality of the construction. Finally, the company transfers the construction to the owner.

3. Strengths in the constructing procedures of BMB Steel Company

Choosing BMB Steel as your construction contractor is a reasonable choice because of the following strengths:

- Detailed drawings that obey technical standards

- High-quality materials with the true origin

- High levels of safety bring satisfaction to customers

- Respectable prices

- Professional and enthusiastic engineers and architects team

Above is detailed information about BMB Steel. We hope that this can be a reference for you - enterprises - when considering construction contractors for your construction projects. If there is any further question, feel free to contact BMB Steel.