The process and design of a steel building structure

- 1. Determining whether steel structure is suitable for the building or not

- 2. Determining appropriate structure and arrangement

- 3. Estimating the cross-sectional area of the structure

- 4. Analyzing the structure

- 5. Inspecting the technical specifications

- 6. Designing the other parts of the building

- 7. Preparing the drawing

Currently, a steel building is a leading trend in construction. What should we learn about when designing and building a steel structure? Look at the article below for more information.

1. Determining whether steel structure is suitable for the building or not

The steel structure is usually used for constructions that require complicated framework systems and the ability to withstand tremendous forces. Besides, these constructions need extensive spans and flexible structures that can easily be assembled and disassembled.

The steel structure is suitable for several types of construction, such as stadiums, bridges, warehouses, factories, garages, and so on.

2. Determining appropriate structure and arrangement

During the arrangement phase, it is important to make a comprehensive design. Design ideas can either come from the relationship between the general system and subsystems or the mechanism and technical experiences. In order to make the arrangement of the steel structure, engineers must consider from the overall perspective, analyze and determine an appropriate arrangement.

Engineers must consider the differences in steel structure during the process. Parts that withstand large forces, like a roof during heavy rain, require suitable curvature and slope. High buildings require structures with a combination of steel and concrete compositions.

A comprehensive mechanical model makes it easier to distribute force. The direction of side beams can be adjusted to fulfill different functions. The designers must have effective solutions to deal with potential risks.

3. Estimating the cross-sectional area of the structure

After planning the arrangement, the engineers must estimate the cross-sectional area of the structure by assuming the shapes and sizes of beams, columns, and braces.

Steel channels and rolled or welded H beams can be used to make steel beams. The height of the section must be from 1/20 to 1/50 of the span. After determining the height and width of the section, designers must calculate the thickness of the steel sheets according to construction standards.

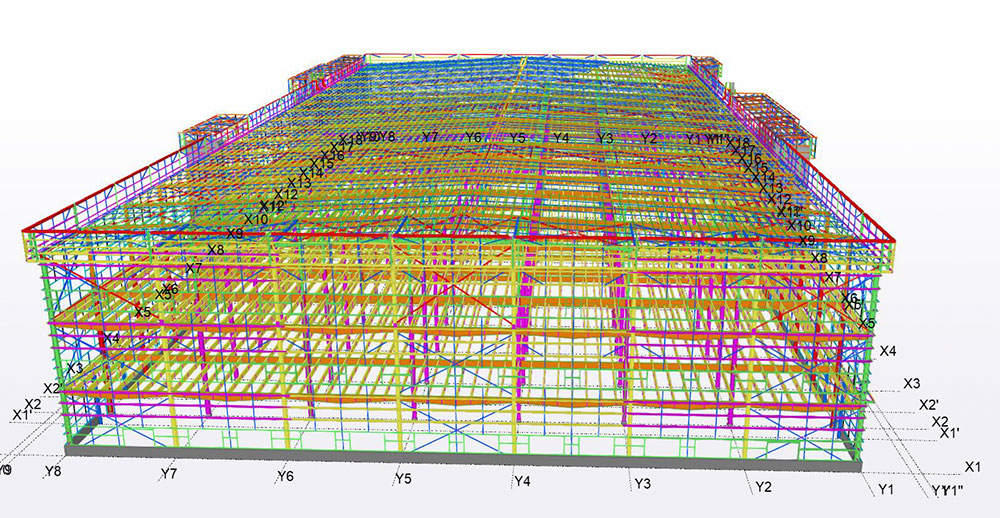

4. Analyzing the structure

During the design process, structure analysis is carried out by analyzing linear elastic with

p-Δ and p-δ considered under particular conditions. This makes the calculation accurate.

5. Inspecting the technical specifications

There must be an inspection report for the output of the structure design. Adjusting the calculation or design model can be based on either the periodic evaluation of total shear force or deformation value.

Besides, there are always differences between values in calculation and reality. In the steel structure design, “practical conditions, concepts, and structures” are more critical factors than quantity numbers. It is important to pay attention to this to avoid technical errors.

6. Designing the other parts of the building

The first step is deciding which materials are used for different building parts. It is easier for management to choose only one type of steel. However, they can combine different types of steel in order to save costs as well as ensure safety.

Besides, some software for steel structures provides services for analyzing the sections. That the machines carried out the inspection process from the beginning till the end makes it much easier for engineers.

Finally, designing the joint points is one of the most critical processes in designing steel structures. Before analyzing the structure, these points must be put into careful consideration. There are three types of points: rigid connection, hinged connection, and semi-rigid connection.

7. Preparing the drawing

There are two types of drawing for different phases of preparing the design: design drawings and detailed drawings.

Design drawings are provided by the design company, while the construction company offers detailed drawings based on the design drawing.

Design drawings are the foundation for making detailed drawings. The design basis, load data, technical data, requirements for materials and design, the structure arrangement, and cross-sectional and primary point design selection must be prepared carefully. The detailed drawing must be detailed enough for the construction and fabricating process.

Above is all information about the process of steel structure design. If you have any further questions, be sure to get in touch with BMB Steel immediately.